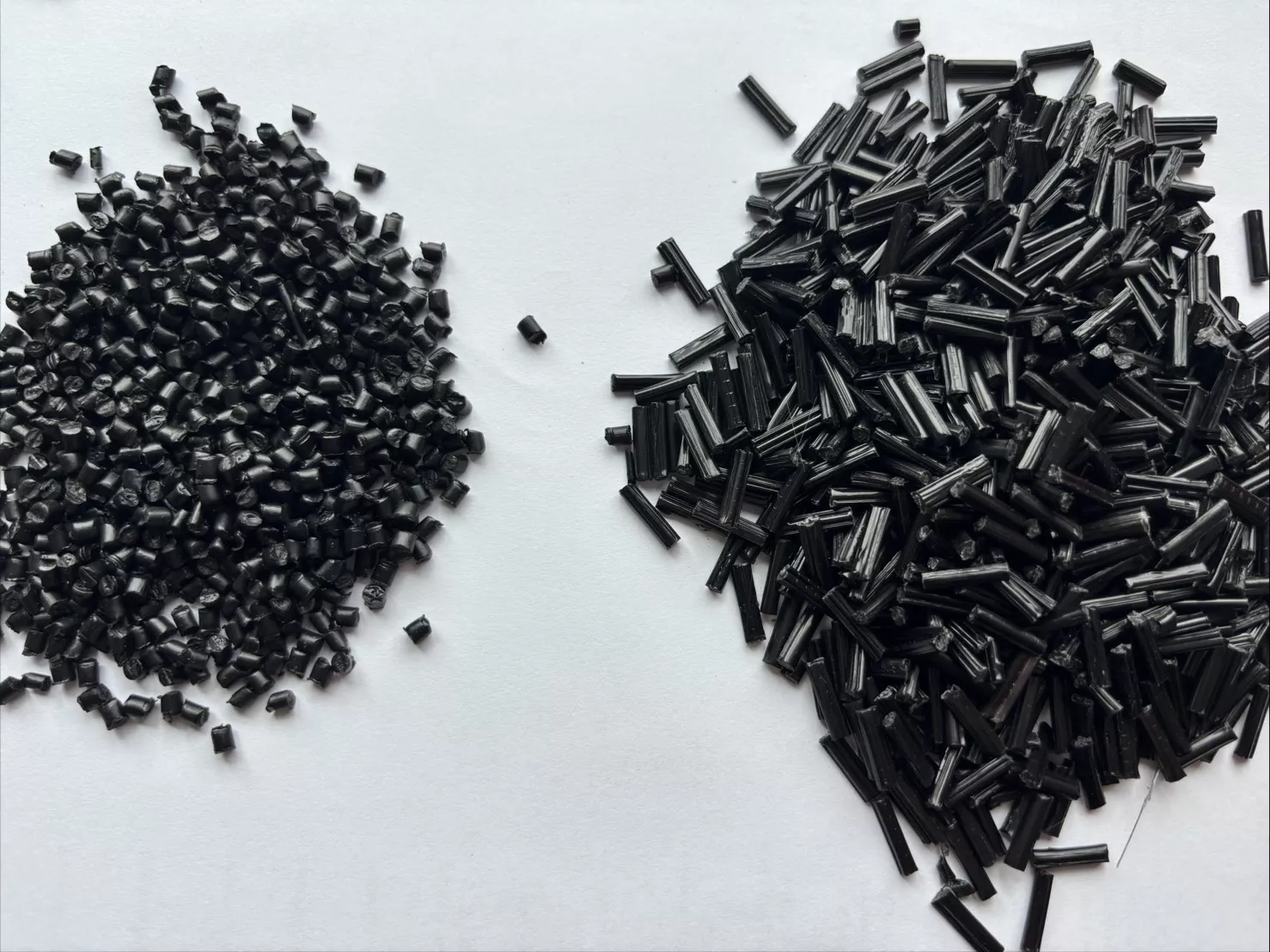

Long Fiber Reinforced Nylon (LFT/LCF) is rapidly becoming the go-to material for replacing metals in high-stress, lightweight structural parts. By using pultruded glass or carbon fibers measuring ~6–25 mm, these materials form an internal “fiber skeleton” during molding, delivering superior stiffness, impact strength, and dimensional stability.

In this guide, we explore the best-performing grades like PA66 LFT40 and PA12 LCF40, explain key mechanical and thermal properties, and highlight real-world applications across automotive, aerospace, medical, and electronics industries.

- LFT (long glass fiber): best value, electrically insulating, robust impact.

- LCF (long carbon fiber): highest specific stiffness/strength and natural conductivity/EMI shielding; typically black/dark; higher cost.

What Is Long-Fiber Reinforced Nylon?

- Matrix families: PA6, PA66, PA12, semi-aromatic PA; for higher temperatures: PPS and PAEK.

- Pellet architecture: Pultruded long-fiber pellets maintain continuous fiber integrity during molding, unlike chopped fibers. This continuous reinforcement network enhances dimensional stability, minimizes warpage, and supports long-term mechanical load—especially critical in metal replacement parts.

- Compared with short fiber PA

- Higher tensile and flexural performance (notably with LCF)

- Better impact and fatigue life

- Lower warpage/deflection with proper design/molding

- Higher HDT and more stable load bearing

- More processing-sensitive—fiber preservation is crucial

📌 Further reading:

- PA-GF vs PA-CF : which to choose —

- Impact-Modified Nylon for high-strength parts —

- Top Plastics for Metal Replacement

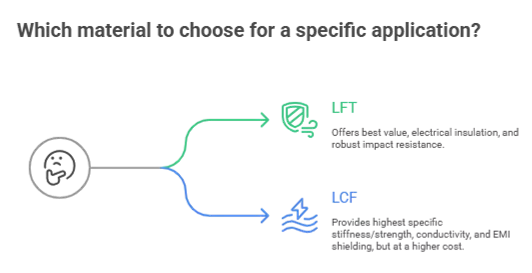

LFT vs LCF: How to Choose

- LFT (Long Glass Fiber): Best value, electrically insulating, robust impact resistance

- LCF (Long Carbon Fiber): Highest specific stiffness/strength, conductivity & EMI shielding, typically black, higher cost

Plastic Grade Overview: Matrix & Performance

- PA6 LFT/LCF: Friendly flow, good price-performance; LFT30–40 for balance, LCF40 for conductivity

- PA66 LFT/LCF: Higher heat and stiffness; LFT40/LCF40 ideal for load-bearing metal replacement

- PA12 LFT/LCF: Low moisture, lightweight; excellent for electronics, optics, UAVs

- Semi-Aromatic PA LFT/LCF (e.g., PA6T/PA6I co-polymers)

: High-temp tolerance; tight tolerances; consider A-surface planning - PPS LFT/LCF: Heat + chemical resistance; ideal for E/E and harsh environments

- PAEK LFT/LCF: Top-tier for aerospace, optics; highest mechanical/thermal performance

📌 Explore related products: PA12 LCF40 · Semi-Aromatic Nylon LCF40 · PPS LCF40 · PAEK LCF45

Typical Property Comparison: Long vs Short Fiber

Actual values depend on grade, formulation, and test conditions. Refer to TDS and part testing. Standards: ISO 527 (tensile), ISO 178 (flexural), ISO 75 1.8 MPa (HDT). Baseline short-fiber comparison uses PA66 GF40.

| Property | PA66 GF40 (Short) | PA66 LFT40 | PA12 LCF40 |

| Density (g/cm³) | 1.46 | 1.45 | 1.20 |

| Tensile Strength (MPa) | 180–210 | 210–230 | 260 |

| Flexural Modulus (GPa) | 9-10 | 9-12 | 18–20 |

| Notched Izod (kJ/m²) | 10-14 | 14–22 | 25 |

| HDT @1.8 MPa (°C) | 220–255 | 230–260 | 150–190 |

| Electrical | Insulating | Insulating | Conductive/EMI potential |

| Color | Light colors feasible | Some fiber show; light colors possible | Black |

| Cost Index | ★★☆ | ★★★ | ★★★★ |

📌 More comparisons:

The New Standard for Lightweighting: Long-Fiber Nylon vs. Metals

When it comes to high-performance structural parts, designers are increasingly turning to long-fiber reinforced nylon to replace traditional metals like aluminum and zinc. This isn't just about reducing weight; it's about achieving superior performance, greater design freedom, and a better overall cost-benefit ratio.

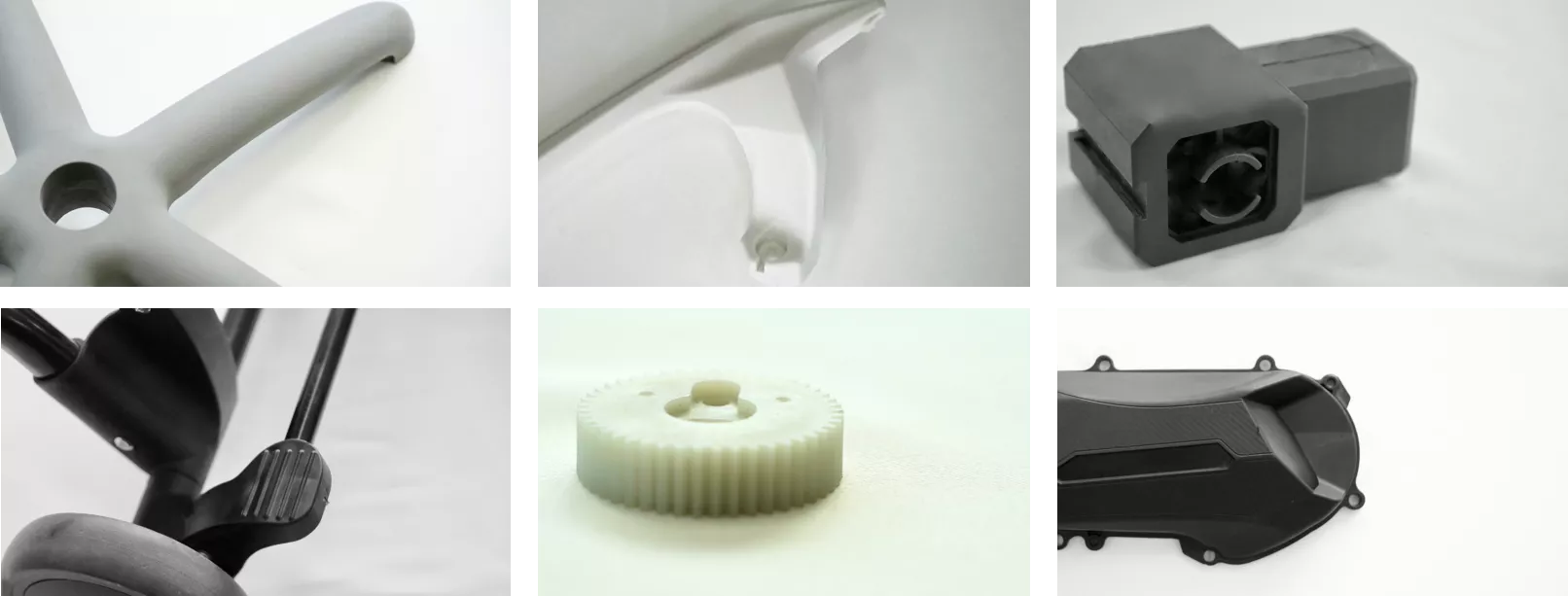

Application Examples for Long Fiber Nylon

| Application | Recommended Grade | Why |

| Smallsat/cubesat brackets | PAEK LCF45 | Heat/creep margin; low outgassing |

| UAV payload rails | PA12 LCF40 | High specific stiffness; lightweight |

| LiDAR mounts | Semi-Aromatic PA LCF40 | Dimensional accuracy |

| Semicon ESD fixtures | PA12 LCF40 / PPS LCF40 | ESD + chemical resistance |

| Medical robotics | PA12 LCF40 / Semi-Aromatic PA LCF40 | Rigid, precise fit |

| High-end audio | PA12 LCF40 | Rigidity with damping |

| Pro cinema rigs | PA12 LCF40 | Black A-surface, stiffness |

| Marine field use | PA12 LCF40 | Corrosion-friendly |

| Test rigs | PPS LCF40 | Thermal & chemical durability |

Frequently Asked Questions (FAQ)

1. What's the real difference between long-fiber and short-fiber compounds?

Long fibers form an interlocked skeleton, boosting stiffness and toughness—but they require careful processing to maintain fiber length.

2. LFT vs LCF: which one to choose?

Choose LFT for value and insulation; LCF for maximum specific strength and EMI. LCF is usually black—use surface textures to manage finish.

3. What matrix to choose: PA6, PA66, PA12, or semi-aromatic PA?

PA6 = best flow; PA66 = heat/dimension; PA12 = low moisture; semi-aromatic PA = high-temp + tight tolerance.

4. Can I get LCF in light colors?

LCF is typically dark. For light colors, use LFT with optimized flow or co-fillers like minerals.

5. How do I spec EMI/conductivity?

Set surface resistivity target, ground effectively, and verify coatings/interfaces.

6. What's the #1 processing rule?

Preserve fiber length! Use low shear, balanced gates, short residence, and correct drying.

7. How to reduce warpage and fiber read-through?

Control gate placement, flow direction, and cooling. Use fillets, textures, and co-fillers to balance aesthetics and strength.

Is Long Fiber Reinforced Nylon the Right Choice for Your Metal Replacement Project?

Long Fiber Reinforced Nylon (LFT/LCF) isn't just a lighter substitute for metal—it's a high-performance engineering material that delivers outstanding strength-to-weight ratio, dimensional stability, and design freedom. When formulated and processed correctly, it meets or exceeds the performance of aluminum, zinc, and other metals in demanding environments.

If you're considering replacing metal components, here's a quick guide to choosing the right grade:

✅ PA66 LFT40: Automotive brackets, load-bearing housings

✅ PA12 LCF40: Lightweight UAVs, electronics

✅ Semi-Aromatic PA LCF40: Precision parts with heat/humidity

✅ PPS LCF40: Chemical/thermal extremes

✅ PAEK LCF45: Maximum performance: aerospace, optics

By choosing the right matrix and long fiber reinforcement, you can not only match metal properties—but surpass them in processability, lifecycle cost, and weight efficiency.

📣 Contact Us for Long Fiber Nylon Solutions

All Around Compounding (All Around Polymer) offers proven long-fiber solutions—like PA12 LCF40, and PAEK LCF45—for customers seeking lighter, stronger, and more efficient components. We provide:

- Trial-grade samples for prototyping

- Design-for-manufacturing (DFM) support

- Data-driven formulation customization

- Expert guidance on tooling, gating, and fiber preservation

📩 Contact us to discuss your application needs—we’ll help you unlock the full performance potential of long fiber reinforced nylon.