Semi-Aromatic Nylon

LCF40

- Semi-Aromatic PA LCF40 (40% Long Carbon Fiber Reinforced Semi-Aromatic Nylon)

- Color: Black

- Features: High strength, low moisture absorption, excellent dimensional stability.

- Certifications: RoHS, REACH

- Scroll down to view the full technical data sheet.

40% Long Carbon Fiber Reinforced Semi-Aromatic Nylon (Semi-Aromatic PA LCF40)

Product Overview

Semi-Aromatic PA LCF40 is a high-strength engineering plastic based on aromatic polyamide and reinforced with 40% long carbon fiber. Compared to aliphatic nylons, semi-aromatic nylons offer lower moisture absorption, better heat stability, dimensional accuracy, and chemical resistance. The long fiber reinforcement significantly enhances mechanical strength, impact resistance, dimensional flatness, and fatigue performance. It is ideal for structural and metal replacement parts used in extreme environments.

Technical Specifications

-

Base Material: Semi-Aromatic Polyamide

-

Carbon Fiber Content: 40% Long Carbon Fiber (LCF)

-

Tensile Strength: 340 MPa

-

Flexural Strength: 580 MPa

-

Notched Impact Strength (23℃): 50 kJ/m²

-

Density: 1.32 g/cm³

-

Moisture Absorption: < 0.3%

-

Color: Black

Application Scenarios

Semi-Aromatic PA LCF40 is ideal for structural applications requiring high heat resistance, heavy load endurance, and long-term dimensional stability:

- Electronics & Electrical: High-temperature connector housings, EV charging station components, control module brackets

- Medical Devices: Rehabilitation equipment frames, mobile device supports, ergonomic structural parts

- Defense Equipment: Rifle stock frames, unmanned system housings, lightweight shields and mounts

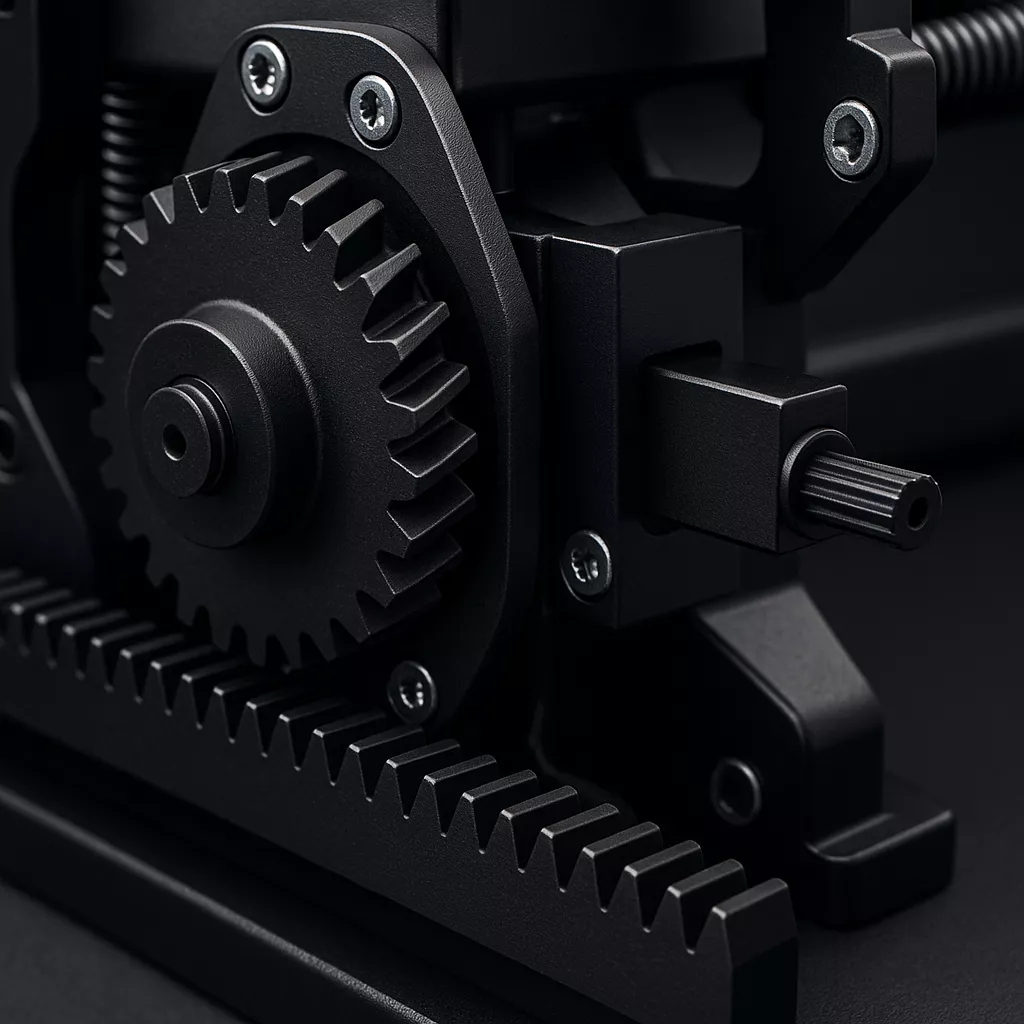

- Industrial Machinery: High-load gears, slide rails, structural supports for long-term operation

- Power Tools: Tool skeletons, grip reinforcements, rotating jigs and impact-resistant parts

Product Applications

Beyond automotive, sporting goods, and aerospace, Semi-Aromatic PA LCF40 is also widely used in industrial machinery, advanced power tools, electronic structures, and medical devices. Its superior thermal stability and rigidity make it an ideal material for maintaining long-term performance under extreme conditions.

Semi-Aromatic Nylon LCF40 Technical Properties

Swipe left or right for more data

| Properties | Test Method | Value | Units | Conditions |

|---|---|---|---|---|

| Density | ISO 1183 | 1.32 | g/cm³ | Dry |

| Tensile Strength at Break | ISO 527 (50 mm/min) | 340 | MPa | Dry |

| Flexural Strength | ISO 178 | 580 | MPa | Dry |

| Flexural Modulus | ISO 178 | 33 | GPa | Dry |

| Notched Impact Strength | ISO 180-1A Charpy, 23°C | 50 | kJ/m² | Dry |

| Melting Point | ISO 3146C (DSC) | 260 | °C | Dry |

| Heat Deflection Temperature | ISO 75, 0.45 MPa | 270 | °C | Dry |

Recommended Reading and Related Resources

Contact Us

If you have any questions or need further technical support, please feel free to contact our team. We are committed to providing you with the best solutions.