Trying to choose between PA and PP plastics for your next project? You're not alone. These two popular thermoplastics—PA (polyamide/nylon) and PP (polypropylene)—are used in everything from engine parts to packaging. In this guide, we'll break down the practical differences in mechanical strength, heat resistance, moisture absorption, cost, and injection molding performance, so you can make the best material decision for your product.Once you've understood how PA and PP compare, you may also want to explore other types of engineering plastics suitable for different applications.

PA vs PP: Property Comparison Chart (Strength, Heat, Cost)

| Property | PA6 / PA66 (Nylon) | PP (Polypropylene) |

| Density | ~1.13–1.15 g/cm³ | ~0.90–0.91 g/cm³ |

| Tensile Strength | High (up to 95 MPa) | Moderate (30–40 MPa) |

| Flexibility | Moderate | High |

| Moisture Absorption | High (up to 2–3%) | Low |

| Heat Resistance | 180–210°C (depending on grade) | ~100–130°C |

| Chemical Resistance | Excellent | Good |

| Wear Resistance | Excellent | Moderate |

| Cost | Higher | Lower |

📌 Compare the properties, applications, and key differences between PA6 vs PA66

Why Choose PA (Polyamide/Nylon) Over PP?

- High Mechanical Strength: Ideal for load-bearing components

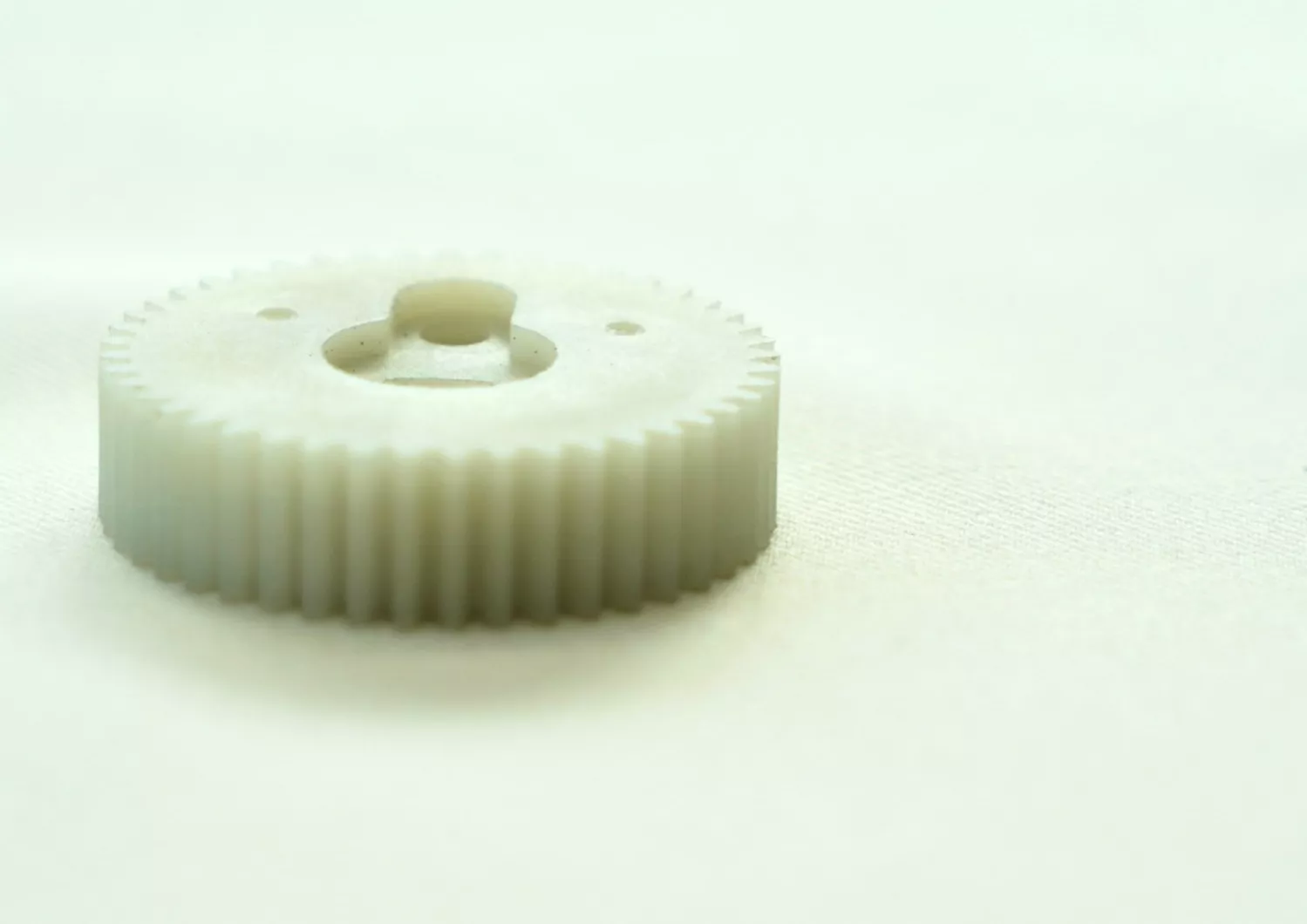

- Excellent Wear and Abrasion Resistance: Great for gears, bushings, and friction-intensive parts

- High Thermal Resistance: Can perform well in high-heat environments

- Significant Differences with Fillers: Can perform significant differences in properties when reinforced with glass fiber, mineral, or impact modifiers

📌 Learn how reinforcing PA with glass fiber affects its density, strength, and processing.

Why Pick PP (Polypropylene) Instead of PA?

- Cost-Effective: Excellent choice for mass production and consumer goods

- Lightweight: Lower density makes it ideal where weight reduction is needed

- Excellent Flexibility: PP resins offer excellent elongation and impact resistance, making it suitable for living hinges, snap-fit parts, and applications requiring bending without breakage

- Very Low Moisture Absorption: Dimensionally stable in humid environments

- Excellent Flowability: Enables efficient injection molding of large components due to superior melt flow characteristics.

📌Read more about PP GF compounds and their processing performance

PA vs PP in Real Applications: Automotive, Packaging, More

| Industry | PA (Polyamide) | PP (Polypropylene) |

| Automotive | Engine covers, air intake manifolds | Interior panels, battery cases, bumper |

| Appliances | Gear wheels, bearing housings | Water buckets, plastic hinges |

| Packaging | High-barrier films, food-grade films | General-purpose containers, caps |

PA vs PP: How to Choose the Right Plastic

Choose PA if you need:

- Strength and rigidity

- Resistance to wear and friction

- Heat resistance above 150°C

- Structural components under mechanical stress

Choose PP if you need:

- Cost-effective production

- Resistance to moisture and chemicals

- Lightweight, low-load applications

- Parts for household, packaging, or simple assemblies

Case Study: Switching Between PA6 GF30 and PP GF30

We've worked with clients who initially used PP GF30 (Polypropylene with 30% glass fiber) for its lightweight nature, low water absorption, and cost-effectiveness, especially in applications like battery casings and structural panels where chemical resistance was critical. However, when the parts required greater mechanical strength, higher heat resistance, and superior dimensional stability under load, they switched to PA6 GF30 (Polyamide 6 with 30% glass fiber). While PA6 GF30 is more expensive and absorbs more moisture, it offers significantly better stiffness, wear resistance, and temperature tolerance, making it ideal for demanding automotive or industrial components.

Conversely, we also helped a client who initially intended to use PA6 GF30 for a large plastic chair. After conducting mold flow and mechanical simulation, we found that PP GF30 would be more suitable due to better processing stability, lower total weight, and easier flow for large and thick sections. This switch improved flowability and reduced material cost, without compromising the structural requirements.

PP GF30 vs PA6 GF30 Comparison

| Property/Feature | PP GF30 | PA6 GF30 |

| Base Material | Polypropylene | Polyamide 6 (Nylon 6) |

| Glass Fiber Content | 30% | 30% |

| Density | ~1.06–1.10 g/cm³ | ~1.35–1.40 g/cm³ |

| Tensile Strength | ~70–90 MPa | ~130–170 MPa |

| Flexural Modulus | ~4,500–6,000 MPa | ~8,000–10,000 MPa |

| Heat Resistance (HDT) | ~120–130°C | ~210–220°C |

| Moisture Absorption | Very Low (~0.1%) | High (~1.5–2.5%) |

| Chemical Resistance | Excellent (especially to acids and bases) | Excellent (especially to oils and greases) |

| Dimensional Stability | Moderate (good in dry settings) | High (especially with proper conditioning) |

| Cycle Time Efficiency | Longer (due to slower crystallization) | Shorter (faster solidification) |

| Cost | Lower | Higher |

| Application Suitability | Electrical housings, battery cases, covers, bumper | Engine parts, structural brackets, gear housings |

PA vs PP Injection Molding: Cycle Time and Processing Tips

One critical factor often overlooked in material selection is cycle time during injection molding. In terms of injection molding efficiency, the PA vs PP injection molding comparison reveals a surprising result: despite PP's lower melting point.

This is because PP has a slower crystallization rate, which extends cooling and demolding times. In contrast, PA6—especially when reinforced—crystallizes and solidifies faster, allowing for shorter molding cycles and higher productivity in mass production environments.

PA vs PP – Frequently Asked Questions

Still wondering how to choose between PA vs PP plastics? Below are answers to the most frequently asked questions by engineers comparing polyamide (nylon) and polypropylene.

1.What is the difference between PA and PP plastics?

PA (nylon) is a strong, wear-resistant material suitable for high-stress applications. PP is lighter, more flexible, and cost-effective—ideal for moisture-resistant, non-load-bearing parts.

2.Can PP replace PA in injection molding applications?

In some cases, yes. PP can replace PA when cost, moisture resistance, or easier flow is a higher priority than mechanical performance. However, PA is still preferred for high-load or high-heat parts.

3. Which is stronger: PA or PP?

PA is significantly stronger than PP. For example, glass fiber reinforced PA6 can reach tensile strengths over 130 MPa, while PP GF30 typically stays under 90 MPa.

4. Is PA more expensive than PP?

Yes. PA usually costs more than PP due to its higher raw material cost and added performance benefits. However, PP can offer savings in applications that don't require high structural strength.

5. Which has better chemical resistance: PA or PP?

It depends on the environment. PP performs better in highly acidic or alkaline conditions, making it suitable for chemical containers and laboratory applications. However, PA generally offers better resistance to oils, greases, fuels, and many organic solvents, especially in automotive and mechanical applications. The right choice depends on the specific chemical exposure involved.

6. Does PA absorb moisture more than PP?

Yes. PA has high moisture absorption (up to 2–3%), which can affect its dimensional stability and mechanical properties. PP, on the other hand, absorbs very little moisture. However, both materials should be properly dried before injection molding to ensure optimal performance, prevent surface defects, and reduce the risk of material degradation during processing.

7. Which plastic has shorter cycle times in injection molding: PA or PP?

Despite its lower melting point, PP often has longer cycle times due to slower crystallization. PA6 tends to solidify faster, especially in glass fiber-reinforced grades, which can result in shorter molding cycles.

8. When should I use PP GF30 instead of PA6 GF30?

PP GF30 is a good option when weight savings, chemical resistance, and cost are more important than mechanical strength. It's also preferable for large parts requiring easier flow and more forgiving molding conditions.

Need Help Choosing?

Whether you're debating between PA and PP or need a custom formulation tailored to your product, All Around Compounding (All Around Polymer Co., Ltd.) can help. We offer expert guidance and customized nylon (PA) and polypropylene (PP) solutions—reinforced with glass fiber, mineral fillers, or impact modifiers.

Contact us today for a material consultation and get the most out of your injection molding, structural, or packaging project.