Choosing the right material for impact-resistant plastic parts is critical—especially for components with notches, weld lines, holes, and thin-wall features. This guide compares Long Carbon Fiber (LCF), Long Glass Fiber (LGF), and Short Fiber Reinforced Nylon with ENZ impact modifiers, helping engineers select the optimal solution for structural integrity, lightweight design, and moldability.

- Long-fiber thermoplastics (LFT)—including LCF (long carbon fiber) and LGF (long glass fiber).

- Short fiber nylon (typically PA6/PA66 with glass fiber), often toughened with ENZ impact modifiers.

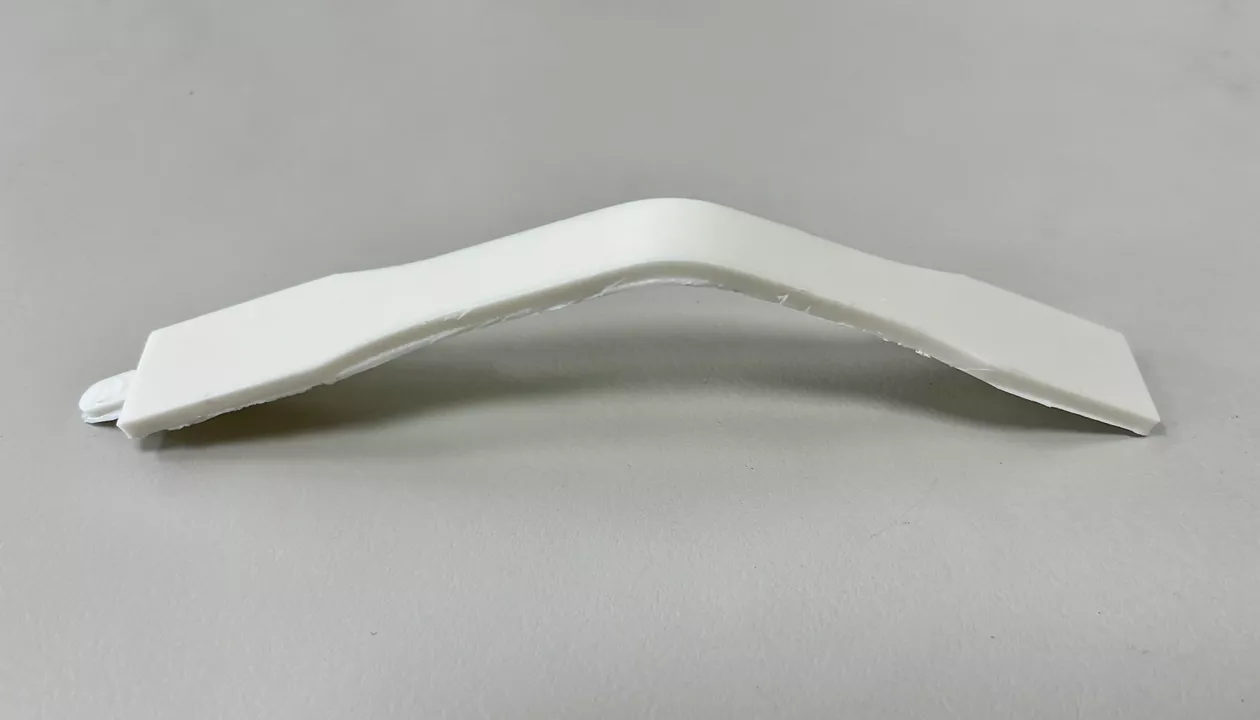

Think of LFT materials as building a mini "rebar " network inside your part, helping it carry load and absorb shocks.

Short Fiber Nylon (PA6/PA66) with ENZ impact modifiers may lack the continuous network of long fibers, but it offers excellent flow for thin-wall molding, supports complex part geometries like ribs and bosses, and delivers superior notched impact performance—especially at weld lines and holes—when properly toughened with ENZ.

The real question isn't "which is best in theory, " but what your part looks like, how it's molded, and where it's used.

If your goal is maximum specific stiffness/strength and impact-fatigue life—especially with weight reduction—LCF rises to the top. If you need great notched impact in thin-wall, long-flow parts with clean surfaces and consistent dimensions, short fiber PA + ENZ often wins on practicality and total cost. LGF sits in between: powerful and proven for large structural parts, with a broader cost window than carbon.

📌Check out the thorough comparison of PA6 vs PA66 : Key Differences, Material Properties, and Best Use Cases

LCF vs LGF vs Short Fiber Nylon: Material Overview

- LCF-Nylon (Long Carbon Fiber):

Carbon fibers are stiff and light. In an LFT matrix they create a continuous load-sharing skeleton that resists crack growth and soaks up impact energy. You'll see the benefit in parts that take repeated knocks or must stay stiff without getting heavy.

- LGF-Nylon (Long Glass Fiber):

Similar "network effect, " typically at a more economical price point than carbon. You still get strong impact performance and durability, especially on larger, thicker parts.

- Short Fiber Nylon (PA6/PA66) + ENZ:

Short glass fibers bring stiffness/strength; ENZ (impact modifiers) add micro "shock absorbers " inside the nylon, which blunt crack tips and boost notched impact—especially at weld lines and around holes. Net result: a friendly molding window, good cosmetics, and solid impact for thin, complex parts.

📌Learn about our Complete Guide to Long Fiber Reinforced Nylon: Best Grades, Properties, and Metal Replacement Applications

Comparing Impact Resistance: Standards & Conditions

Use consistent standards/conditions when comparing: ISO 179/ISO 180 (Charpy/Izod) or ASTM D256, and consider temperature (e.g., -30 °C, 23 °C) and moisture conditioning for PA.

| Scenario | LCF-Nylon | LGF-Nylon | Short Fiber PA (+ ENZ) | Notes |

| Drop/High-energy impact | Excellent energy absorption and impact-fatigue; high specific stiffness helps stability | Strong overall; proven for large structural parts | ENZ boosts impact; practical on thin/complex parts | Gate/flow orientation still critical |

| Notched & weld-line toughness | Very good, but abrupt notches still need design radii | Very good; sensitive to sharp defects | Standout at weld lines & holes with ENZ | Smooth thickness transitions amplify gains |

| Low-temperature impact | Retains ductility and stiffness well (grade-dependent) | Retains network benefit (grade-dependent) | ENZ families available for low-T ductility | Match ENZ type/ratio to target T |

| Impact-fatigue life | Often best-in-class | Strong | Improved vs. un-toughened short fiber | Validate on part-level fatigue |

| Dimensional stability & surface | Stiff; manage fiber print; good for thin walls with proper gating | Manage fiber print/warpage | Usually easiest for appearance/tolerance | Often highest mass-production yield |

| Total cost & cycle | Premium material/cycle sensitivity | Mid-to-high | Often best value | Consider full landed cost, yield, scrap |

How ENZ Improves Short Fiber Nylon

ENZ is an impact modifier designed for PA6/PA66. Think of ENZ as many tiny, well-dispersed cushions inside the nylon—when a crack tries to start at a notch or a weld line, those cushions spread out the stress, so the crack is less likely to run. In practice, that means higher notched Izod/Charpy, better weld-line strength, and more reliable low-temperature behavior. Typical loadings are roughly 5–30%, tuned to the glass fiber level, target impact, and the stiffness/heat-deflection you still need.

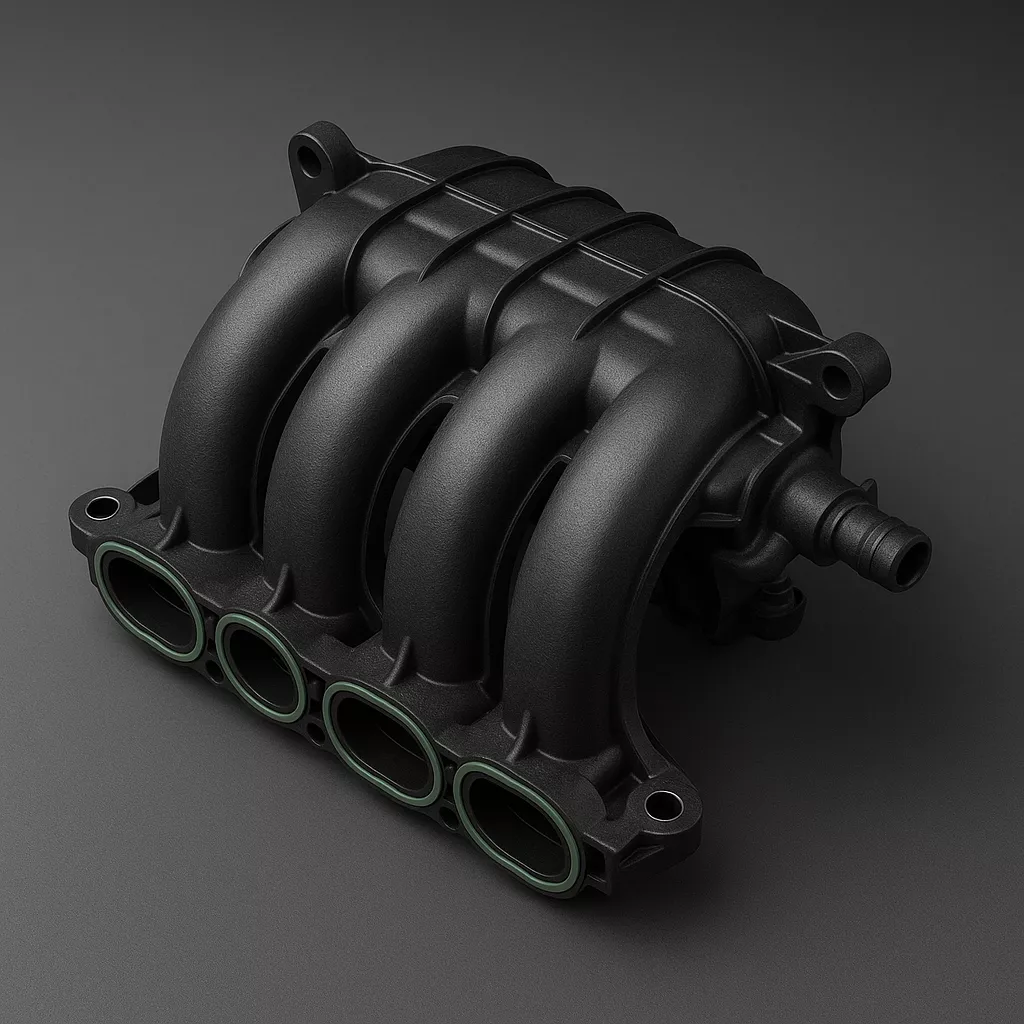

When to Choose LCF-Nylon

- You need maximum specific stiffness/strength, impact-fatigue durability, or weight reduction with structural robustness.

- The part faces tough temperature or chemical environments (see PPS/PAEK bases).

- You can protect fiber length (screw design, residence time) and manage orientation with gating/flow.

📌Learn the datails of High-Performance Polyamides : PA46, PA6I, PA6T, and PA9T Comparison Guide

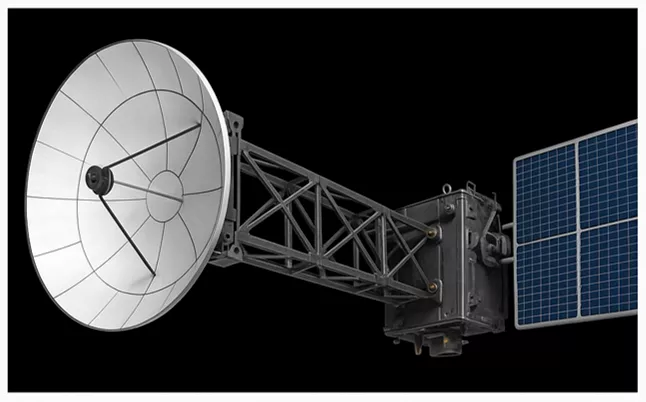

When to Choose LGF-Nylon

- Large structural parts with established processing and cost windows.

- Balanced impact/stiffness with broader material availability.

When to Choose Short Fiber PA + ENZ

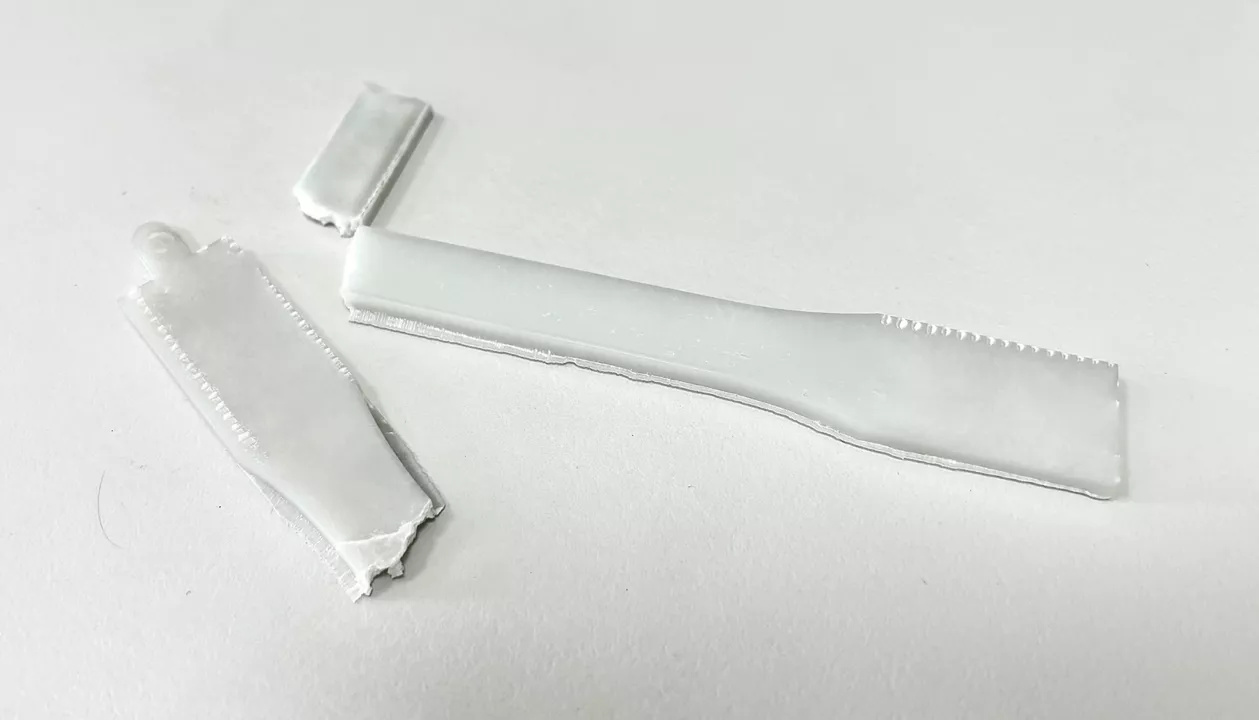

- Thin-wall, long-flow, multi-rib, complex features where molding window, surface, and tolerances dominate.

- You need strong notched values and weld-line strength without LFT premiums.

Real-World Performance: LCF vs LGF vs Short Fiber PA+ENZ

1) Pure impact hits and drop events

- LCF: Excellent at absorbing energy while staying stiff; great for parts that get hit hard or often.

- LGF: Very capable for big structural components; widely used with predictable processing.

- Short fiber + ENZ: Impressive toughness for most products, especially when parts are thin or intricate—and at a more approachable cost.

2) Notches, weld lines, and holes (where failures actually start)

- LCF & LGF: Strong materials, but sharp geometries still need radii and smoother transitions.

- Short fiber + ENZ: This is where ENZ shines—notched impact and weld-line toughness improve significantly, reducing brittle breaks in those tricky spots.

3) Thin walls and long flow paths

- LCF & LGF: Possible, but require careful gating and process control to preserve fiber length and orientation.

- Short fiber + ENZ: Naturally easier to mold thin sections and complex ribbing; often higher yield with better surfaces.

4) Weight and stiffness per weight

- LCF: Best stiffness-to-weight; strong candidate for lightweighting without giving up strength.

- LGF: Heavier than carbon at the same fraction but still a big stiffness bump vs. unfilled or short fiber only.

- Short fiber + ENZ: Balanced; not a stiffness-per-weight leader, but often "stiff enough + tough enough " for housings and brackets.

5) Appearance, color, & dimensional consistency

- LCF & LGF: Manageable with good tooling, but watch fiber print and warpage.

- Color: LCF parts are naturally dark gray/black due to carbon fiber—light/bright colors are hard without painting, coating, or overmolding. LGF allows more color flexibility, but fiber show-through can make pale colors look speckled; texture helps.

- Short fiber + ENZ: Typically cleaner surfaces and tighter tolerances with less effort.

- Color: The most color-friendly; darks and mid-tones are straightforward, and even lighter colors are achievable (texture helps hide glass).

6) Budget and timing

- LCF: Premium performance at a premium cost; process discipline required.

- LGF: A strong middle ground.

- Short fiber + ENZ: Frequently the best value when you tally material, cycle time, yield, and scrap.

7) Processing accessibility & equipment

- LCF: Premium performance but needs gentle handling to preserve fiber length—lower screw RPM, modest backpressure, generous gates/runners, smooth flow paths, and wear-resistant hardware. Long-fiber pellets may call for larger nozzles/check rings and careful purging.

- LGF: Similar principles to LCF but a bit more forgiving; still avoid excessive shear and sharp flow turns.

- Short fiber + ENZ: Easiest to mold on standard injection equipment with a wider process window; great for thin walls/long flow and usually higher yield. As with all PA, drying and moisture control are critical.

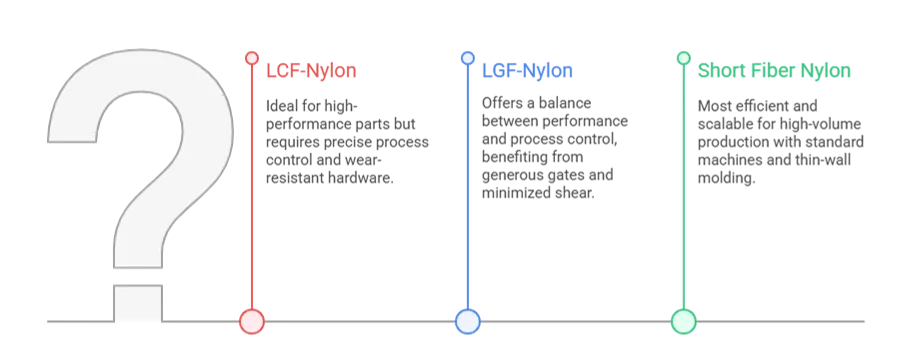

✅Long Carbon Fiber (LCF) requires wear-resistant hardware, low screw RPM, and gentle flow paths to preserve fiber length. It's ideal for high-performance parts but demands tighter process control.

✅Long Glass Fiber (LGF) is slightly more forgiving than LCF but still benefits from generous gates and minimized shear.

✅Short Fiber Nylon (PA6/PA66) with ENZ modifiers offers the widest processing window, allowing use on standard injection molding machines with thin-wall molding and long-flow part geometries, making it the most efficient and scalable option for high-volume production

Key takeaway:

If your part must survive repeated or severe hits while staying light and stiff, start with LCF (and consider LGF if budget is tighter). If your part is thin, detailed, and appearance-critical, start with short fiber PA + ENZ—you’re likely to get the impact you need with smoother molding and friendlier economics.

The table below provides indicative numeric ranges that support these takeaways, allowing side-by-side comparison of LCF, LGF, and short-fiber PA + ENZ under standard test conditions.

Numbers at a Glance: Impact & Stiffness (23 °C, PA Systems)

Here are indicative key performance ranges for Impact Resistance and Flexural Modulus of LCF-Nylon, LGF-Nylon, and Short-Fiber PA + ENZ (at 23 °C under ISO/ASTM methods). These figures facilitate side-by-side comparison for structural design and impact-toughening. (Values are indicative ranges at 23 °C under common ISO/ASTM methods; compare within the same standard/conditioning. Validate on part-level tests.)

| Property | LCF-Nylon (≈40% CF) | LGF-Nylon (≈40% GF) | Short-Fiber PA (GF25–35) + ENZ |

| Density (g/cm³) | 1.15–1.35 | 1.35–1.55 | 1.20–1.40 |

| Flexural Modulus (GPa) | 12–25 | 8–14 | 5–9 |

| Notched Izod @23 °C (kJ/m²) | 8–25 | 10–30 | 20–60 |

| Unnotched Impact @23 °C | often NB/very high | often NB/very high | often NB/very high |

| Low-T Notched Impact (−30 °C) | mid–high | mid–high | mid–high (grade-dependent ENZ) |

Color & Finish

Color and Surface Finish Considerations for LCF, LGF, and Short Fiber Nylon with ENZ:

- LCF (long carbon fiber): Expect black/dark gray as the native look; carbon's color dominates the base polymer (PA12, semi-aromatic PA, PPS, PAEK). For light/bright colors, plan for paint, coating, or cosmetic overmold.

- LGF (long glass fiber): Wider colorability than LCF, but pale/solid colors may show fiber telegraphing; texture (MT/VDI) helps.

- Short fiber + ENZ: Best color flexibility and surface cosmetics of the three. For light/clean colors, pair with PA-carrier masterbatch, mind UV packages (slight darkening), and use mold texture to hide fibers.

Long Carbon Fiber (LCF) materials naturally appear black or dark gray due to the inherent color of carbon fiber, making light or bright color options limited without secondary processing like painting or overmolding.

Long Glass Fiber (LGF) provides wider color flexibility than LCF but may cause fiber telegraphing, especially in pale colors; textured mold surfaces help mitigate this.

Short Fiber Nylon (PA6/PA66) with ENZ impact modifiers delivers the best balance of colorability, surface quality, and dimensional precision, making it the top choice for appearance-critical applications.

- General tips:

- For color-critical parts, minimize regrind and excessive shear (streaks).

- Texture/matte finishes hide fibers better than high gloss.

- Mineral fillers can reduce print-through but may affect impact—balance with ENZ/GF.

- Validate color under your actual lighting and temperature (aging can shift hue).

Processing Accessibility — Quick Setup Notes

| Material family | Dryer & moisture | Screw/Shear | Gating/Flow | Notes |

| LCF (long carbon fiber) | Dry to spec; keep moisture low to protect toughness | Low RPM, moderate backpressure; avoid mixing elements that chop fibers | Large, radiused gates/runners; gentle turns; avoid thin knife-edges | Wear-resistant barrels/nozzles; careful purging; premium cycle control |

| LGF (long glass fiber) | Same discipline as LCF | Low–moderate shear; protect fiber length | Generous gates help; manage orientation | Slightly more forgiving than LCF; watch fiber print |

| Short fiber PA + ENZ | Dry PA6/PA66 properly (avoid hydrolysis) | Standard screws typically fine; wider window | Works well with thin walls & long flow | Often highest mass-production yield; easy color matching |

Frequently Asked Questions (FAQ)

1. Is LCF always better than LGF or short fiber nylon for impact resistance?

Not always. LCF usually leads on stiffness-to-weight and impact-fatigue. LGF is a strong, cost-balanced structural option. For thin, complex, appearance-critical parts, short fiber PA + ENZ often meets impact targets with easier molding and better yield.

2. When should I consider ENZ for short fiber nylon?

Use ENZ when you need higher notched impact and weld-line toughness (holes, knit lines, sharp transitions) or low-temperature ductility—common in thin-wall housings and ribbed parts.

3. How much ENZ should I add?

Start with pilot trials around 10–20%, then refine within ~5–30% based on target impact, GF level, flow, stiffness/HDT, and dimensional needs.

4. What about color—can I make long-fiber parts light or bright?

LCF parts are naturally dark gray/black; light/bright colors typically need paint, coating, or overmolding. LGF allows more color flexibility but can show fiber telegraphing in pale colors. Short fiber + ENZ is usually the most color-friendly.

5. Which is easiest to mold?

Short fiber PA + ENZ has the widest processing window and is most forgiving for thin walls/long flow. LGF is more forgiving than LCF, but both long-fiber families need gentle shear and appropriate gates/runners.

6. How do moisture and drying affect impact?

PA absorbs moisture, which affects impact and dimensions. Dry to spec before molding and control moisture during storage and testing for consistent results.

7. Which metrics should I compare for impact?

Use notched Izod/Charpy (ISO 179/180 or ASTM D256) at the same temperature/conditioning. If your geometry has weld lines or notches, prioritize notched data. Always confirm with part-level drop and impact-fatigue tests.

8. Can I keep stiffness while boosting impact?

Yes—balance GF level, ENZ loading, and (if needed) mineral fillers. Expect some trade-off; tune the formulation and process to hit both toughness and stiffness/HDT targets.

9. Any quick design tips to avoid brittle failures?

Add radii at corners, smooth thickness transitions, keep rib ≤ ~60% of wall thickness, and place gates to control weld-line locations and fiber orientation.

10. What if my part must be light, stiff, and survive repeated knocks?

Start with LCF; it offers excellent specific stiffness/strength and impact-fatigue. If budget or processing simplicity is key for a large structural part, evaluate LGF. For thin/complex parts with color and surface needs, try short fiber PA + ENZ.

11. Will LCF/LGF hurt surface finish?

They can show fiber print and increase warpage risk. Good tooling, texture (matte/MT/VDI), and process control help. Short fiber + ENZ typically gives the cleanest surface.

12. Do I need special hardware for long-fiber materials?

Plan for wear-resistant barrels/nozzles, larger/radiused gates and runners, lower screw RPM, and moderate backpressure to protect fiber length. Purge carefully.

Featured LCF Grades for Impact-Resistant Plastic Parts

If your part requires lightweight stiffness, repeat-impact durability, and performance under thermal or chemical stress, our Long Carbon Fiber (LCF)-reinforced nylon grades are engineered to deliver structural strength with reduced weight. Explore the options below to match your part geometry, environmental demands, and performance goals:

- PA12-LCF40 – Offers low moisture absorption and excellent dimensional stability, making it ideal for thin-wall components in humid environments.

- Semi-Aromatic Nylon LCF40 – Combines high heat resistance with strong impact-fatigue performance, suitable for parts exposed to elevated temperatures or mechanical cycling.

- PPS-LCF40 – Designed for chemical resistance, tight dimensional control, and thermal stability in aggressive operating conditions.

- PAEK-LCF45 – Withstands extreme temperatures and harsh environments, making it a top choice for metal-replacement in structural applications requiring long-term durability.

Match the right LCF grade to your mechanical requirements, geometry constraints, chemical exposure, and target surface quality—and confirm with part-level testing.

Match the Right Material to Your Design and Performance Needs

Choosing the optimal fiber-reinforced nylon depends on your part's geometry, impact requirements, processing constraints, and target cost.

- Use LCF (Long Carbon Fiber) for the highest stiffness-to-weight ratio, impact-fatigue durability, and performance in lightweight structural applications.

- Consider LGF (Long Glass Fiber) for cost-effective, large structural parts with proven strength and processability.

- Select Short Fiber Nylon (PA6/PA66) with ENZ impact modifiers for thin-wall, appearance-critical, or high-yield molded parts requiring strong notched impact and surface quality.

No matter the material, always validate your design with part-level testing—including drop, fatigue, and notched/unnotched impact tests—under real-world moisture and temperature conditions to ensure consistent performance.

Need help choosing the right grade for your part?

Share your geometry, impact targets, operating temperature, and appearance goals—and our technical team will recommend the most suitable material formulation, along with processing guidance to get you from mold to market faster.

📩 Contact us or Request a Material Recommendation