When choosing engineering plastics, two materials often come up in the conversation: PA (Polyamide/Nylon) and PPO (Polyphenylene Oxide). Each offers a unique combination of mechanical, thermal, and chemical properties, making them suitable for a wide range of industries—from automotive and electrical to consumer goods.

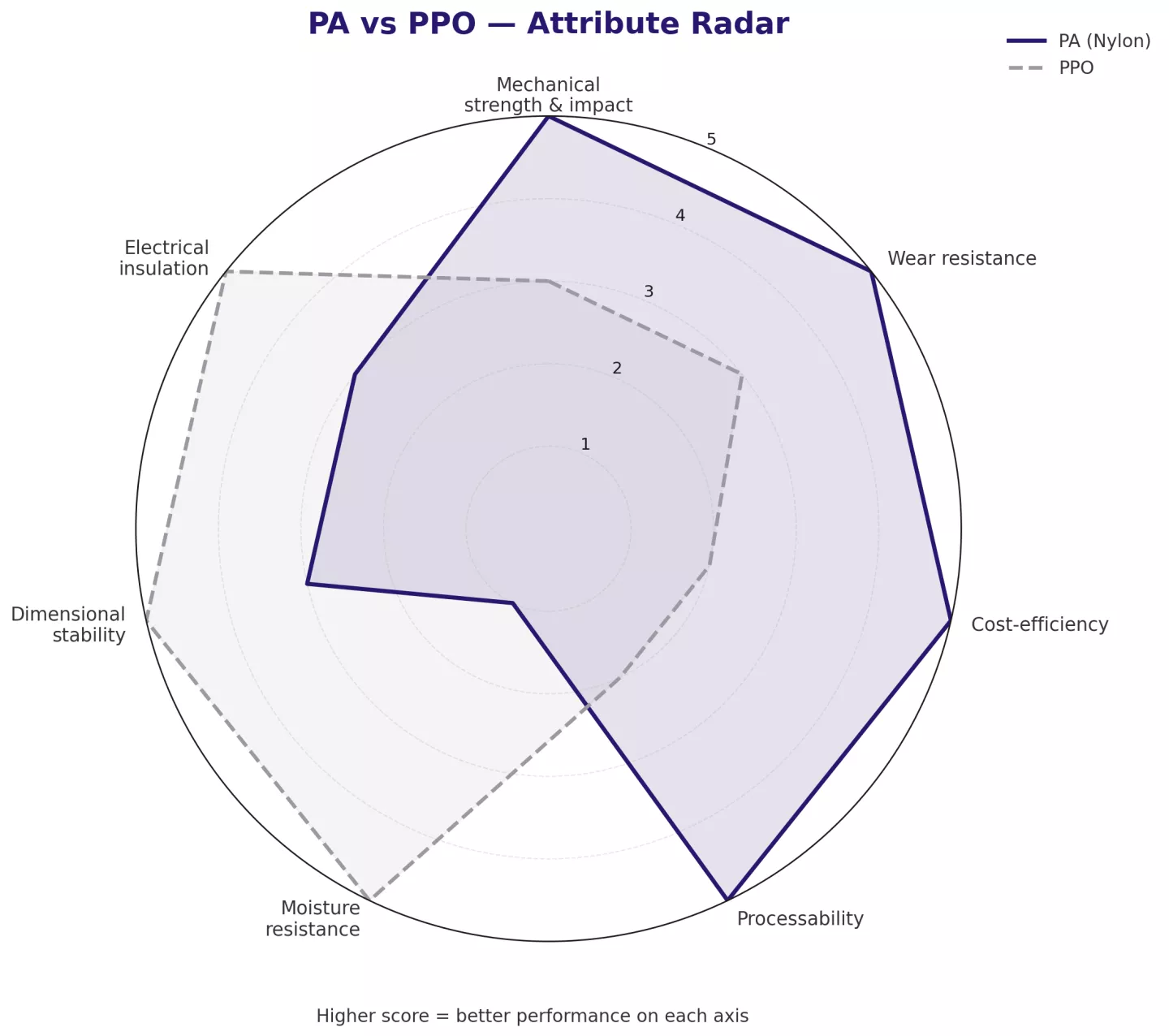

But how do you decide between PA and PPO? PA (Nylon) offers superior mechanical strength and impact resistance, while PPO excels in dimensional stability, electrical insulation, and low moisture uptake. In this guide, we'll compare these two high-performance thermoplastics across key selection factors, answer common questions, and help you make an informed material choice for your next project.

What Is PA (Polyamide/Nylon)?

PA, commonly known as Nylon, is a semi-crystalline thermoplastic with excellent mechanical strength, flexibility, and wear resistance. Common types include PA6 and PA66, used in structural parts, gears, and housings.

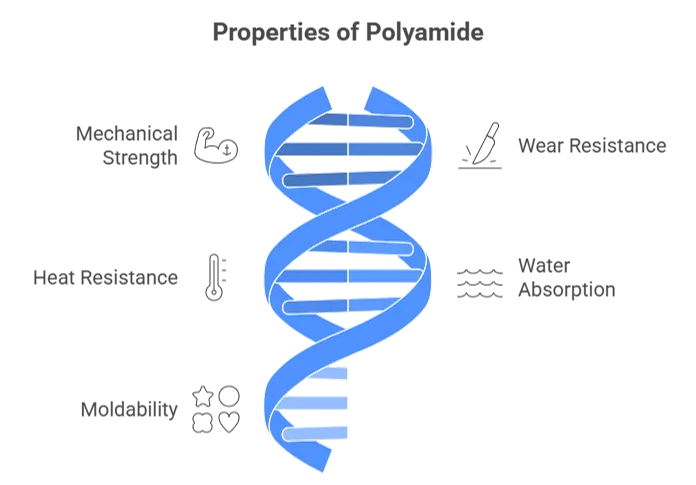

Key properties of PA (Polyamide/Nylon):

- High tensile and impact strength

- Good wear and abrasion resistance

- Moderate heat resistance (up to ~120–150°C depending on type)

- High water absorption (can affect dimensional stability)

- Excellent moldability

📌 Learn the in-depth introduction about the most commonly seen Polyamide/Nylon -- PA6, PA66 & PA12.

What Is PPO (Polyphenylene Oxide)?

PPO, often blended with polystyrene to form Noryl™, is an amorphous engineering plastic with excellent dimensional stability and electrical insulation.

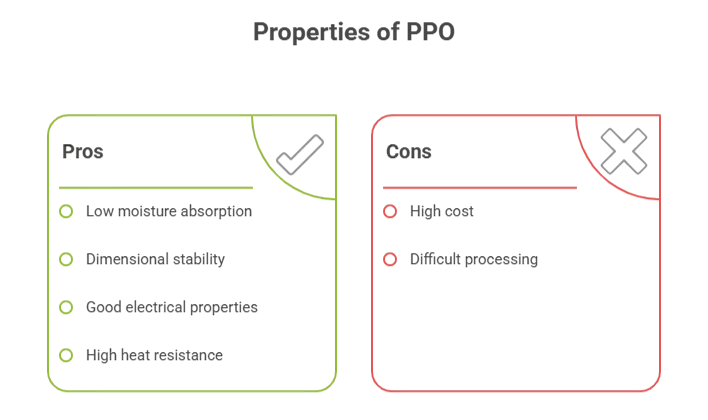

Key properties of PPO (Polyphenylene Oxide):

- Very low moisture absorption

- Excellent dimensional stability

- Good hydrolytic and electrical properties

- Higher heat resistance (up to ~200°C in some grades)

- Higher cost and more difficult to process than PA

These performance differences stem from fundamental variations in their molecular structure.

Structural Difference at a Glance

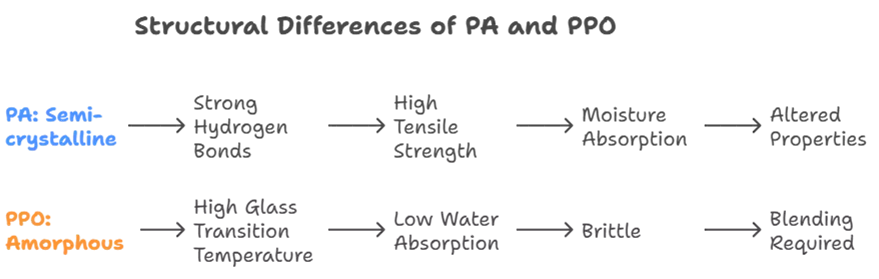

Before we look at the performance table, it's important to understand the molecular structures that drive these differences. While PA and PPO may appear similar in some applications, their chemical architectures result in very different behaviors.

- PA (Polyamide/Nylon) is a semi-crystalline polymer, meaning it has both ordered (crystalline) and disordered (amorphous) regions. Its polymer chains form strong hydrogen bonds, which contribute to high tensile strength, toughness, and excellent wear resistance. However, this structure also makes PA prone to moisture absorption, which can alter its mechanical and dimensional properties. With the right additives—glass fiber (GF), mineral fillers (MF), GF+MF, or GF plus an impact modifier—PA can retain the expected mechanical strength even in humid conditions.

📌 At All Around Polymer (All Around Compounding Co., Ltd.), we offer low-moisture-absorption nylon compounds to mitigate moisture-related problems. Explore our Low-Moisture Nylon product line.

- PPO (Polyphenylene Oxide) is an amorphous polymer, made up of aromatic rings and ether linkages. This structure leads to a high glass transition temperature, low water absorption, and excellent dimensional stability, especially in humid or high-heat environments. However, PPO is more brittle and often requires blending to improve processability and impact performance.

PA vs PPO: Performance Comparison (Quick View)

| Property | PA (Polyamide/Nylon) | PPO (Polyphenylene Oxide) |

| Heat Resistance | Moderate (PA66: ~150°C) | High (up to ~200°C) |

| Moisture Absorption | High | Very low |

| Dimensional Stability | Moderate (impacted by water) | Excellent |

| Impact Strength | High (especially PA6) | Moderate |

| Electrical Insulation | Moderate | Excellent |

| Processability | Excellent | More difficult |

| Cost | Lower | Higher |

| Common Applications | Gears, housings, fasteners | Electrical parts, pump housings |

Detailed Property Comparison

| Property | PA6 / PA66 (Polyamide) | PPO (Polyphenylene Oxide) |

| Glass Transition Temperature (Tg) | PA6: ~50–70°C, PA66: ~70–80°C |

~210–220°C |

| Melting Point | PA6: ~220°C, PA66: ~260°C |

Amorphous (no true melting point) |

| Tensile Strength | ~60–80 MPa | ~70–100 MPa |

| Flexural Modulus | ~2–3 GPa | ~2.5–4 GPa |

| Elongation at Break | ~30–120% (depending on grade) | ~3–5% |

| Moisture Absorption (24 h) | ~1.0–1.5% | ~0.06% |

| Oxygen Index (LOI) | ~24% | ~32% |

| Dielectric Strength | ~10–30 kV/mm (depending on grade) | ~19–21 kV/mm |

| Processing Temperature | ~240–290°C | ~270–300°C (requires drying; often blended) |

Which Is Better: PA or PPO?

Choose PA (Nylon) if you need:

- High mechanical strength and impact resistance

- Good wear resistance for gears, bearings, sliding parts

- Cost-efficiency and excellent moldability

Choose PPO if you need:

- Dimensional stability in humid or high-temperature environments

- Excellent electrical insulation

- Very low water absorption for tight tolerances

PPO/PA Blends: A Hybrid Solution

In some applications, engineers don't have to choose strictly between PA or PPO. Instead, they may opt for PPO/PA blends that combine the best of both materials—leveraging the dimensional stability and low moisture uptake of PPO with the toughness and flexibility of PA.

One well-known example is Noryl™, a family of PPO blends designed for applications requiring excellent electrical insulation, low moisture absorption, and good processability. These blends are often used in automotive housings, electrical connectors, pump bodies, and fluid-handling systems where balanced mechanical and thermal properties are critical.

By blending PPO with PA, manufacturers can reduce brittleness, improve flow characteristics, and tailor performance to meet specific environmental and mechanical requirements. This hybrid approach offers greater design freedom when single-material solutions fall short.

Applications: Where Are PA and PPO Used?

| Category | PA (Polyamide/Nylon) | PPO (Polyphenylene Oxide) |

| Automotive | Engine covers, fasteners, cable ties | Fluid tanks, pump components |

| Electrical/Electronics | Connectors, housings | Switchgear, enclosures, insulators |

| Consumer/Industrial | Gears, sports equipment | Water filter housings, medical device parts |

PA vs PPO – Frequently Asked Questions

1. Is PPO stronger than PA?

No. While PPO has better thermal and dimensional stability, PA generally offers higher tensile strength and impact resistance.

2. Which absorbs more moisture, PA or PPO?

PA absorbs significantly more moisture, which can affect dimensional accuracy. PPO has excellent moisture resistance.

3. Can PPO replace PA in most applications?

Not always. PPO is better for electrical and high-heat environments; PA is preferred when flexibility and toughness are critical.

4. Is PPO more expensive than PA?

Yes. PPO is generally more costly due to raw material pricing and processing complexity.

5. What’s the difference between PPO and Noryl™?

Noryl™ is a commercial family of PPO blends (often with polystyrene) designed for improved processability while retaining PPO’s advantages.

6. Can PPO and PA be blended?

Yes. PPO is often blended with PA (or PS) to improve flow and impact performance, creating versatile materials for balanced properties.

PA or PPO—Which One Should You Choose?

Both PA and PPO are high-performance thermoplastics, but they serve different engineering needs.

Choose PA (Polyamide/Nylon) when:

- High tensile strength and impact resistance are required

- The part will see wear, friction, or fuel/oil exposure

- Cost-efficiency and moldability are key

Choose PPO when:

- Dimensional stability in humid or high-temperature environments is critical

- Electrical insulation is a primary requirement

- Low water absorption is essential to maintain tight tolerances

Explore More Engineering Plastic Comparisons

Want to explore more material comparisons and application guides? Here are popular resources from our engineering plastics series:

Understand how polyamide compares to polypropylene in key aspects like mechanical strength, molding behavior, and industrial use.

A side-by-side look at two widely used thermoplastics in automotive, electrical, and appliance industries.

Learn how these two polyamide grades differ in moisture absorption, flexibility, and chemical resistance.

Discover high-performance polymers that can replace metal in demanding structural applications.

Compare polycarbonate, nylon, and PPO-based materials for optimal heat resistance, transparency, and impact strength in headlamp applications.

Need Help Choosing?

Whether you're comparing PA and PPO or considering a custom blend, All Around Compounding (All Around Polymer Co., Ltd.) can help. We offer expert guidance and customized nylon (PA), PPO, and PPO/PA solutions—reinforced with glass fiber, mineral fillers, or impact modifiers.

Contact us today for a material consultation and get the most out of your injection molding, structural, or electrical application.