In the world of engineering plastics, Polybutylene Terephthalate (PBT) and Nylon (Polyamide, PA) are among the most commonly used thermoplastics due to their balance of strength, thermal resistance, and processability. Both materials are widely adopted in industries like automotive, electrical & electronics, and consumer appliances — but how do you decide between them?

This article compares PBT vs. Nylon (PA6/PA66) across key performance factors to help you make the right material selection for your application.

Still looking for more options for your products? Check our full product lines to find our the best technical properties for your needs.

What Is PBT?

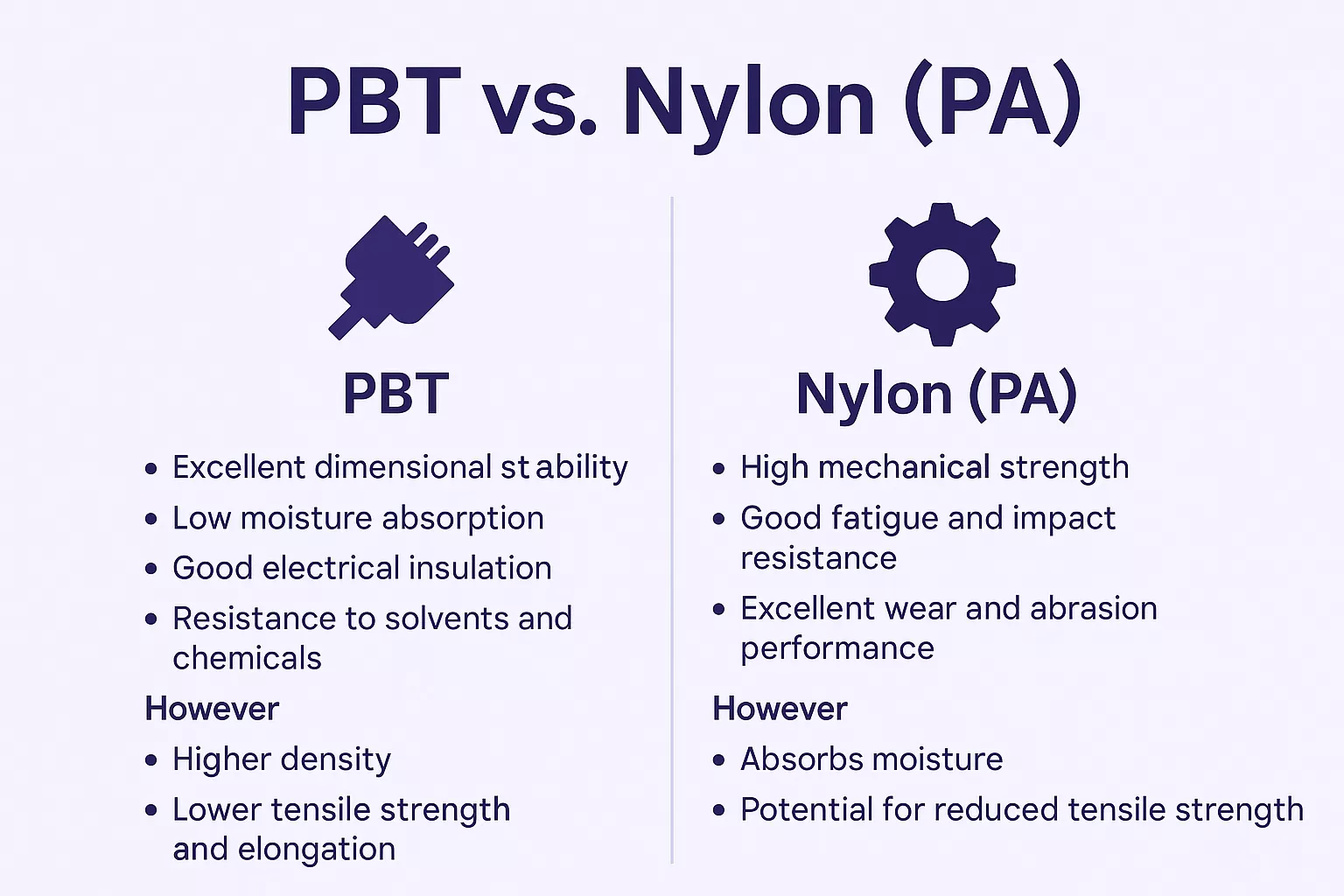

PBT (Polybutylene Terephthalate) is a semi-crystalline thermoplastic polyester known for:

- Excellent dimensional stability

- Low moisture absorption

- Good electrical insulation

- Resistance to solvents and chemicals

However, PBT has a higher density and typically lower tensile strength and elongation at break compared to Nylon, which can result in reduced toughness and a tendency to become brittle under impact or stress.

It is commonly used in connectors, switches, sensor housings, and appliance parts, especially where long-term shape retention and electrical properties are essential.

What Is Nylon(PA)?

Nylon, especially PA6 & PA66, is a family of thermoplastics with:

- High mechanical strength

- Good fatigue and impact resistance

- Excellent wear and abrasion performance

However, Nylon tends to absorb moisture over time, which can lead to reduced tensile strength but increased toughness. This moisture uptake may also cause warpage and dimensional changes, especially in applications requiring tight tolerances. To overcome these challenges, many engineers turn to reinforced Nylon compounds—such as PA66 filled with glass fiber and mineral additives—which significantly improve moisture resistance and ensure long-term shape retention. Learn how glass fiber and mineral-filled PA66 enhances dimensional stability in demanding environments.

Nylon materials are often chosen for automotive components, gears, bearings, and structural parts due to their strength-to-weight ratio and durability.

Read more about Different types of Nylon (PA)

PBT vs. Nylon (PA) – Key Differences at a Glance

PBT vs. PA: Property Comparison Table

|

Properties |

PBT (Base / Reinforced) |

Nylon (PA6 / PA66) (Base / Reinforced) |

| Density | 1.31 (unreinforced) | 1.13 (unreinforced) |

| Water Absorption | Very low (~0.1%), stable without additives | High (PA6 up to 2.5%, PA66 ~1.5%), may require additives for moisture resistance |

| Dimensional Stability | Excellent, even without reinforcement | Fair in unfilled grade; improves significantly with GF or mineral fillers |

| Tensile Strength | Moderate (30–90 MPa with GF) | High (up to 250 MPa with GF reinforcement) |

| Impact Resistance | Moderate; improved with elastomers | High in PA6, moderate in PA66; impact-modified grades available |

| Heat Resistance | ~120–150°C (with GF reinforcement) | PA6: up to ~180°C; PA66: up to ~210°C (with GF) |

| UV Resistance | Requires stabilizers or UV masterbatch | Also requires stabilizers for long-term outdoor use |

| Chemical Resistance | Excellent to oils, greases, fuels; weak to strong acids | Good general resistance; sensitive to strong acids and oxidizers |

| Friction/Wear Resistance | Good for sliding parts | Excellent, especially in PA66 and self-lubricating grades |

| Cost | Lower | PA6 more economical; PA66 moderately higher but still cost-effective |

Notes:

Both PBT and Nylon can be modified with additives (e.g., UV stabilizers, flame retardants, impact modifiers) to meet specific application needs. For projects requiring tailored mechanical strength, impact resistance, or enhanced thermal stability, consider toll compounding services that offer customized nylon formulations and reinforcements.

For fair comparison, this table considers commonly used PA6 GF reinforced grades, not just base resin alone.

Application Considerations

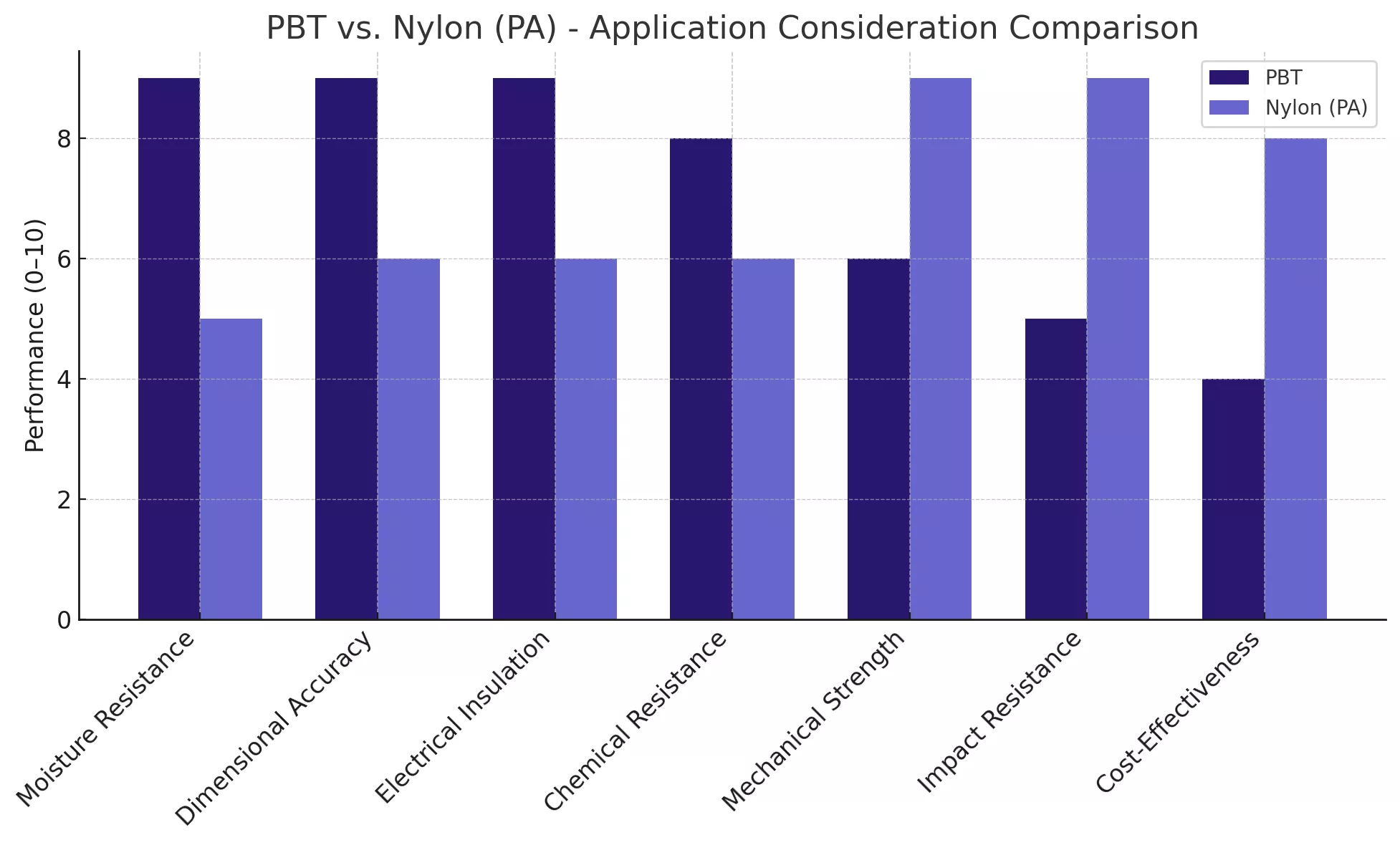

Choose PBT when:

- You need low moisture uptake for tight tolerances

- Electrical insulation and dimensional accuracy are critical

- Your part is exposed to oils, greases, or outdoor environments

Choose Nylon when:

- You need mechanical strength and toughness

- Parts are subject to repeated impact or wear

- Cost is a concern, and PA6 offers a more economical solution

PBT vs. Nylon (PA): Visual Comparison of Application Performance

PA66 vs. PBT for Electrical Applications

In electrical and electronic applications, the choice between PA66 and PBT is common. While PA66 offers superior mechanical properties and higher temperature resistance, PBT often performs better in terms of moisture resistance, insulation, and dimensional stability — all of which are crucial for connectors, switches, and terminal blocks.

For environments with high humidity or precision-fitting requirements, PBT compounds (especially UL94 V-0 flame-retardant grades) are preferred. On the other hand, PA66 may be chosen when parts also require mechanical load-bearing strength in addition to insulation.

Glass-Fiber Reinforced Options

Both PBT and Nylon can be glass-fiber reinforced to improve stiffness, strength, and thermal performance. For example:

- PBT GF30: Suitable for connectors requiring shape retention at higher temperatures.

- PA66 GF30: Used in automotive brackets or structural parts requiring mechanical durability

Did you know? PA66 reinforced with up to 50% glass fiber can replace metal in structural automotive and industrial parts by offering high rigidity, lightweight advantages, and excellent fatigue resistance.

Sustainability and Recycling

- PBT is recyclable but less commonly reused compared to PA.

- Recycled PA6 and PA66 are more readily available and cost-effective, especially in regions with strong plastic recovery infrastructure.

If sustainability is a focus, recycled nylon compounds may offer a better balance of performance, cost, and environmental benefit.

FAQ: PBT vs. Nylon(PA)

Q1. Which is stronger: PBT or Nylon (PA6/PA66)?

PA6 and PA66 generally offer higher tensile, toughness and impact strength compared to PBT, making it more suitable for structural parts under mechanical load.

Q2. Is PBT more dimensionally stable than Nylon?

Yes. PBT absorbs significantly less moisture than PA6 or PA66, which helps maintain dimensional stability in humid environments.

Q3. Can PBT replace Nylon in automotive parts?

In some cases, yes — especially for electrical housings or parts that require surface finish and stability over mechanical strength. But PA66 remains superior for high-strength or high-temperature load-bearing applications.

Q4. Which is better for electrical connectors: Nylon or PBT?

PBT is often preferred in electrical connectors due to its lower moisture absorption and better dimensional accuracy, especially in high-humidity environments.

Q5. Which has lower environmental impact: Nylon or PBT?

Nylon, especially recycled PA6 and PA66, tends to have a lower environmental impact due to wider availability of recycling streams and established reuse infrastructure. While PBT is recyclable, it is less commonly reused in practice. For projects prioritizing sustainability, recycled Nylon compounds are often the better choice.

Case Study: Nylon MF vs. PBT MF in Automotive Headlight Housings

Background

An automotive OEM was evaluating two material options for the rear housing of LED headlamps — a critical component that must maintain dimensional stability, resist heat buildup, and provide a smooth surface for sealing and assembly.

The two candidates:

Design Considerations

- Heat Resistance: LED modules generate moderate but consistent heat; material must maintain form under prolonged thermal exposure.

- Dimensional Stability: Precise sealing is needed to prevent moisture and dust ingress.

- Surface Quality: Smoothness affects reflective coating adherence and sealing function.

- Cost Efficiency: Material and processing cost directly impact vehicle profitability.

Test Results & Performance

| Criteria | PA6 MF30 | PBT MF20 |

| Thermal Resistance | 160–170°C | ~150°C |

| Moisture Sensitivity | Moderate (needs drying before molding) | Lower (drying recommended), stable dimensions even in humidity |

| Warpage / Shrinkage | Slightly higher due to moisture uptake | Lower shrinkage, better retention of shape |

| Surface Finish | Matte, less glossy, but surface can be good with proper injection | Smoother |

| Processing Cost | Slightly higher resin cost; faster demolding, higher temperature | Lower material cost; slightly longer cycle with lower temperature |

| Overall Score | Good for high-strength and recyclability | Better for sealing precision & stability |

Note: For improved surface finish and thermal performance in PA6 MF, consider using Nylon-6 nanocomposite compounds.

Final Decision

The OEM selected PBT MF20 for this specific headlamp housing project due to:

- Better dimensional control in humid and hot environments

- Lower processing temperatures, improving efficiency and cost effectiveness in mass production

However, PA6 MF remains a qualified and competitive alternative, particularly for interior light housings where higher thermal resistance and recyclability are prioritized.

Lesson Learned

Both PBT MF and Nylon MF are viable options for automotive headlamp applications. The key is to weigh:

- Environmental exposure

- Tightness of tolerances

- Cosmetic vs. structural requirements

- Long-term thermal loading

Conclusion: Nylon or PBT?

The choice between PBT and Nylon ultimately depends on your application needs:

- For dimensional stability, electrical applications, and low cost and water uptake – go with PBT.

- For high mechanical demands, impact resistance, or eco-friendly options – Nylon (especially PA66 or modified PA6) may be more suitable.

Still unsure? At All Around Compounding (All Around Polymer Co., Ltd.), we specialize in customizing nylon compounds for unique requirements — from high-glass-fiber formulations to impact-modified and mineral-filled solutions.

Ready to Choose the Right Engineering Plastic?

Whether you're comparing PBT vs. PA66/PA6 or seeking a custom nylon solution, our experts are here to help.

👉 Contact us today and let's develop the material that fits your application — all around the world.