Looking for a high-performance nylon that resists moisture, chemicals, and wear? PA12 (Polyamide 12) is a versatile engineering plastic trusted in automotive, medical, and industrial applications. This article explores what PA12 is, why it stands out, and how to choose the right grade for your application.

What Is PA12 (Nylon 12)?

PA12, or Polyamide 12, is a semi-crystalline thermoplastic that belongs to the nylon family. Known for its low moisture absorption and high chemical resistance, PA12 also offers a distinctive advantage: a more transparent appearance compared to PA6 or PA66. This makes it an excellent choice for both performance-critical and appearance-sensitive applications.

Still looking for more options for your products? Check our full product lines to find our the best technical properties for your needs.

PA12 Material Properties: Low Moisture, Flexibility & More

PA12 stands out among engineering plastics due to its unique combination of characteristics:

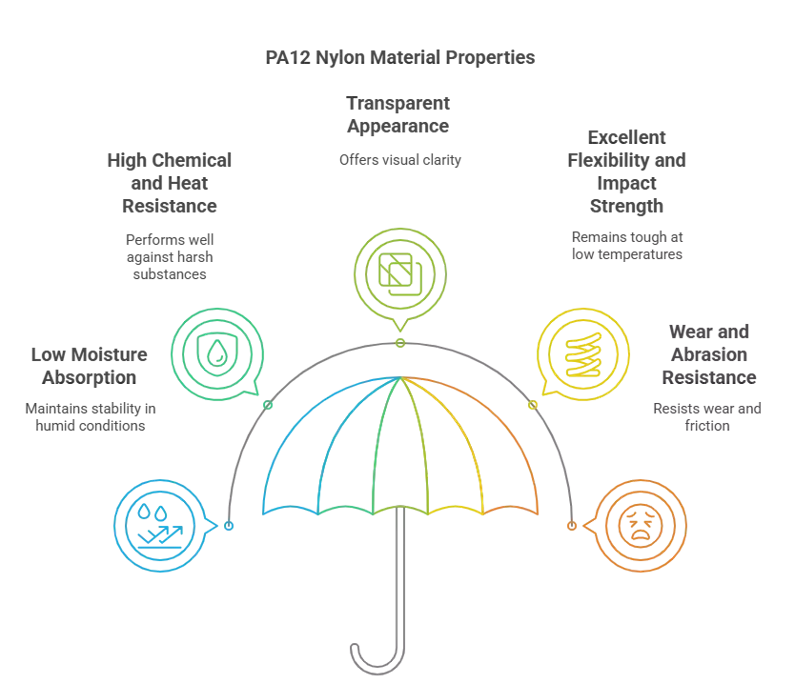

Low Moisture Absorption

PA12 absorbs much less water than PA6 or PA66, which helps it maintain dimensional stability and mechanical properties even in humid environments. This moisture resistance is one of the most valuable PA12 nylon material properties, especially in moisture-sensitive or outdoor applications.

Learn the difference and comparison of PA6 & PA66.

High Chemical and Heat Resistance

PA12 performs well against oils, fuels, greases, and many industrial chemicals, offering reliable PA12 chemical resistance in both automotive and industrial settings. This makes it especially valuable for components exposed to aggressive fluids or harsh environments.

Transparent Appearance

Unlike PA6 and PA66, PA12 exhibits a higher level of natural transparency. This characteristic makes it ideal for products that require both functionality and visual clarity.

Excellent Flexibility and Impact Strength

PA12 remains tough and flexible even at low temperatures, making it suitable for dynamic and safety-critical components.

Wear and Abrasion Resistance

With high surface hardness and a smooth texture, PA12 is highly resistant to wear and friction, even under continuous use.

Key Technical Data of PA12 (Nylon12 Material Properties)

PA12 nylon material properties include high toughness, low density, excellent impact resistance, and reliable chemical resistance. Below are typical values:

|

Properties |

Typical Value |

| Density | 1.03 g/cm³ |

| Melting Point | ~178°C |

| Water Absorption (24h, 23°C) | < 0.25% |

| Tensile Strength | 45-55 MPa |

| Elongation at Break | 200-300% |

| Flexural Modulus | 1300–1700 MPa |

| Notched Izod Impact | No break (high toughness) |

| Cost | High |

Note: Actual values may vary depending on the specific PA12 grade and formulation.

Learn more about PA12 density, melting point, and performance with different reinforcement in our full spec sheet.

PA12 vs PA6 and PA66: What's the Difference?

For engineers comparing PA12 vs PA6 and PA12 vs PA66, key differences lie in moisture absorption, flexibility, and chemical resistance.

|

Properties |

PA12 | PA6 | PA66 |

| Density (g/cm³) | 1.03 g/cm³ | 1.12 g/cm³ | 1.13 g/cm³ |

| Melting Point | 178°C | 226°C | 270°C |

| Moisture Absorption | Very Low | High | Moderate |

| Tensile Strength | 45-55 MPa | 70-80 MPa | 80-90 Mpa |

| Chemical Resistance | Excellent | Moderate | Moderate |

| Flexibility | High | Excelletn | Moderate |

| Transparency | Semi-Clear | Opaque | Opaque |

| Dimensional Stability | Excellent | Moderate | Good |

| Cost | Very High | Lower | High |

While PA6 and PA66 are cost-effective and strong, PA12 is the better option when moisture resistance, flexibility, or chemical stability are critical.

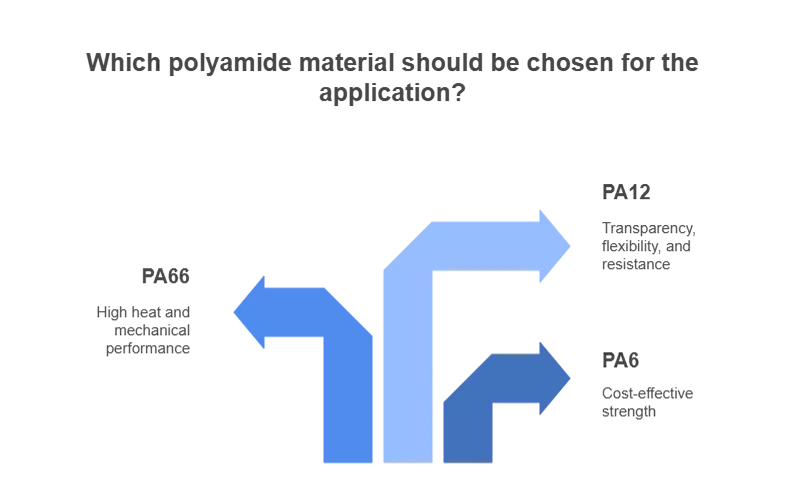

PA6, PA66 and PA12 Choosing Guide:

- Choose PA6 for cost-effective strength. (Check out 10 Essential Insights on PA6 (Nylon 6) You Need to Know.)

- Choose PA66 for high heat and mechanical performance. (Discover the benefits of PA66 compounds for structural and high-temperature applications.)

- Choose PA12 when transparency, flexibility, moisture resistance, or chemical resistance are key priorities.

What Is PA12 Used For? Applications by Industry

Thanks to its outstanding properties, PA12 is widely used in the following sectors:

- Automotive: Fuel lines, brake lines, air brake tubing, cable sheathing

- Electronics: Connectors, sensor housings, insulation components

- Medical: Catheters, tubing, surgical instrument housings

- Industrial: Pneumatic tubing, gears, conveyor rollers, seals

- 3D Printing: Powder bed fusion using PA12 powders for durable, functional prototypes

Learn how to choose the materials if you want to replace metals with plastics.

Consumer Case: Sports Bottle with PA12

A famous Taiwanese brand has adopted PA12 for its sports water bottles to combine durability, heat resistance, and a clean, modern look. PA12's semi-transparent appearance gives the bottles a premium feel, while its heat and chemical resistance ensures lasting performance in hot environments, such as cars or outdoor use.

Thanks to its low moisture absorption, the bottles maintain their shape and clarity over time, offering users a hygienic and reliable hydration option.

This case highlights PA12's ability to deliver on both appearance and performance in everyday consumer products.

Industrial Case: Nike's 3D Printed Footwear with PA12

Another well-known example is Nike, which has used PA12 in the production of high-performance components via 3D printing. PA12's excellent durability, flexibility, and precision make it ideal for prototyping and producing custom midsoles and structural footwear parts. The material's resistance to fatigue and cracking ensures that it can withstand the repetitive stress seen in athletic performance.

Nike's use of PA12 demonstrates how the material supports innovation in design and manufacturing, especially when rapid prototyping, lightweight performance, and form retention are required. This reinforces PA12's status as a go-to material not only for traditional applications, but also for cutting-edge technologies.

Frequently Asked Questions (FAQs) about PA12

Q1. Is PA12 suitable for outdoor applications?

Yes, PA12 has excellent UV and weather resistance.

Q2. How does PA12 compare to PA6 in moisture resistance?

PA12 absorbs significantly less water, maintaining dimensional accuracy and mechanical performance.

Q3. What is the melting point of PA12?

~178°C, while PA6 is ~226°C and PA66 is ~270°C.

Q4. Is PA12 more expensive than PA6 or PA66?

Yes, but its superior properties often justify the cost in demanding applications.

Q5. Is PA12 good for injection molding? What processing methods are suitable for PA12?

PA12 can be processed via injection molding, extrusion, and powder-based 3D printing (SLS).

Reinforced PA12: How to Enhance Strength of PA12 for Demanding Applications

In addition to standard PA12, reinforced PA12 compounds—such as PA12 with glass fiber or mineral fillers—offer improved stiffness, dimensional stability, and heat resistance. These grades are ideal for structural parts or applications that require higher load-bearing capability, such as automotive connectors, industrial housings, and machinery components. Reinforced PA12 maintains the excellent chemical and moisture resistance of the base polymer while delivering enhanced mechanical performance.

PA12 + Glass Beads/Mineral Fillers vs PA12 + Glass Fiber

When customizing PA12 materials for performance, two common fillers are glass fiber and glass beads.

- PA12 + Glass Fiber (PA12 glass filled) significantly improves tensile strength, flexural modulus, and thermal stability, making it ideal for mechanical and load-bearing applications.

- PA12 + Glass Beads/Mineral Fillers improves surface smoothness, dimensional accuracy, and impact resistance, making it suitable for aesthetic parts, housings, and functional components that require tight tolerances.

Understanding the difference between PA12 + glass fiber vs PA12 + glass beads helps engineers choose the right formulation for their specific performance and design needs.

Interested in exploring these material options? Contact us to learn more about our glass-filled PA12 grades.

Is PA12 Expensive? Cost Comparison with PA6 and PA66

Compared to PA6 or PA66, PA12 material price is typically higher due to its superior performance and lower production volume. However, for high-value applications requiring long-term durability, flexibility, and chemical resistance, the investment in PA12 often leads to lower maintenance costs and improved product life cycles.

When Should You Choose PA12 Over Other Nylons?

If your application involves exposure to moisture, chemicals, or low temperatures, PA12 is likely the right choice. Though it comes at a higher cost than PA6 or PA66, its performance benefits often justify the investment—especially in critical or safety-related parts.

Conclusion

PA12 (Nylon 12) is a high-performance polyamide that offers unmatched moisture resistance, flexibility, and chemical stability. Whether you're designing automotive systems, precision electronics, or industrial equipment, PA12 delivers durability and long-term reliability.

Ready to switch to PA12?

Not sure which PA12 grade is right for your needs? Request a datasheet or expert consultation. At All Around Compounding (All Around Polymer Co., Ltd.), we specialize in advanced nylon compounds, including custom PA12 formulations. Let us help you find the perfect balance of performance, durability, and efficiency—no matter the application.

👉 Contact us today to discuss your PA12 needs.