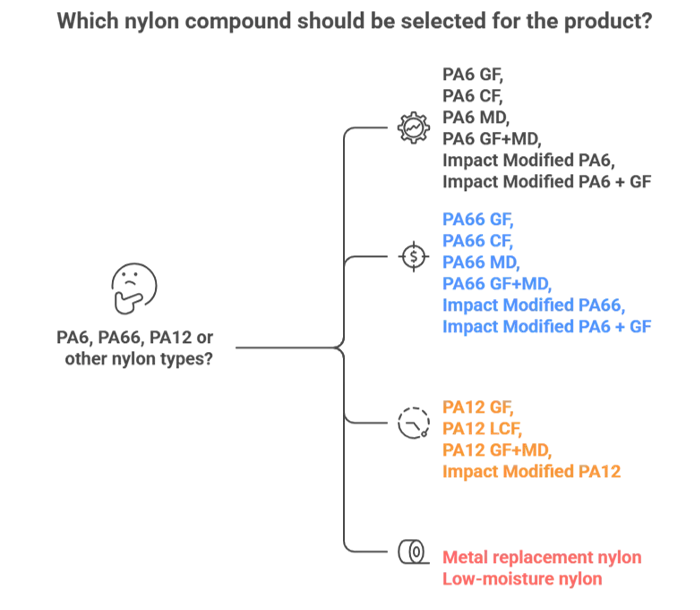

Selecting the right nylon compound can often feel like navigating a maze of technical data — PA6, PA66, PA12, GF30, impact-modified… the list goes on. At All Around Compounding, we've spent over 20 years helping manufacturers navigate that maze — engineering nylon compounds that deliver optimal performance, durability, and efficiency. Whether you're designing a durable automotive bracket, a moisture-resistant connector, or a lightweight structural part, your choice of nylon compound will ultimately define your product's success in terms of performance, cost-effectiveness, and long-term reliability.

With so many variations — from glass-fiber-reinforced to impact-modified grades — knowing what to focus on is essential. In this guide, we'll walk through five key factors that separate a good material choice from a great one, and explore the latest trends in nylon compounding that are transforming modern manufacturing.

📌To explore what is nylon compounds and how they work for different applications, please read: Nylon Composite Materials: 6 Main Types, Advantages, and Applications

1. Thermal Resistance — Finding the Right Heat-Resistant Nylon Compound

Every nylon grade offers a different level of heat resistance — and understanding those differences is key to selecting the right compound.

- PA6 provides a balanced performance-to-cost ratio but may soften earlier under continuous high temperatures.

📌 To better understand the material of PA6, check out 10 Essential Insights on PA6 (Nylon 6) You Need to Know

- PA66 offers superior heat-aging resistance and maintains mechanical integrity in long-term use around 120 °C.

📌 For a deeper look into PA66's mechanical strength, heat resistance, and typical uses, read What is PA66 (Nylon 66) – 8 Must-Know FAQs.

- PA12, though slightly lower in heat resistance than PA6, excels when temperature stability must be combined with low moisture absorption — making it ideal for environments that experience both heat and humidity.

📌 Looking for a lightweight yet durable nylon material? Learn more in What Is PA12 (Nylon 12)? Properties, Benefits, and Key Industrial Applications.

- PA46 or high-heat stabilized grades push this boundary even further, performing reliably in components exposed to engine heat, friction, or continuous mechanical stress.

📌 If you're choosing materials for industrial design or product manufacturing, the Engineering Plastics Guide is a great place to start.

| Grade | Heat Resistance | Key Advantages | Common Uses |

|---|---|---|---|

| PA6 | Up to 100–110 °C | Balanced strength-to-cost ratio | Structural parts, general-use components |

| PA66 | Up to 120–130 °C | Excellent heat-aging and strength retention | Under-the-hood parts, gears |

| PA12 | Around 90–100 °C | Low moisture absorption, stable in humid heat | Electrical connectors, sensors |

| PA46 | Up to 150 °C | Exceptional high-temp and wear resistance | Engine covers, friction parts |

Tip: When thermal stability is critical, choose grades that are heat stabilized or highly crystallized to minimize softening and maintain stiffness under load.

📌 Types of Nylon (Polyamide): Everything You Need to Know About PA6, PA66, and Beyond

2. Dimensional Stability and Moisture Absorption

One of nylon's well-known challenges is its tendency to absorb moisture from the environment. This can lead to swelling, reduced stiffness, and warpage — a serious concern in precision parts.

- PA12 is widely recognized for its exceptionally low moisture absorption, offering outstanding dimensional stability and long-term precision. It is ideal for applications such as electrical connectors, sensors, and precision gears that operate in humid or outdoor environments.

- Low-moisture-absorption PA6 or PA66 compounds provide a more cost-effective alternative to PA12 when density or total component weight is not a major concern. These modified grades deliver improved moisture resistance compared to standard nylons while maintaining good mechanical strength and processability.

- Glass fiber and mineral reinforcement further reduces water uptake while enhancing rigidity and dimensional consistency.

Engineering insight: Even small improvements in moisture control can make a significant difference in long-term dimensional stability, especially in humid or outdoor environments.

3. Mechanical Strength and Toughness

Nylon compounds can be engineered to achieve specific performance targets — from lightweight flexibility to near-metal stiffness. By adjusting the type and ratio of reinforcement, fillers, and modifiers, each formulation offers a distinct balance of strength, toughness, dimensional stability, and durability.

Here are the most common nylon compound families and how they perform across different applications:

Different reinforcement systems create unique property profiles — from lightweight flexibility to metal-like stiffness.

| Compound Type | Base Polymer | Main Advantages | Typical Applications |

|---|---|---|---|

| Glass Fiber Reinforced (GF) | PA6 GF, PA66 GF, PA12 GF | Excellent tensile and flexural strength; high stiffness; good dimensional stability | Structural components, brackets, gears, housings |

| Mineral Filled (MF) | PA6 MF, PA66 MF | Improved dimensional stability and surface finish; reduced warpage | Precision housings, covers, thin-wall components |

| Glass + Mineral Reinforced (GF+MF) | PA6 GF+MF, PA66 GF+MF, PA12 GF+MF | Balanced stiffness and dimensional accuracy; reduced warpage vs pure GF | Automotive housings, mechanical parts requiring low distortion |

| Carbon Fiber Reinforced (CF) | PA6 CF, PA66 CF, PA12 LCF | Exceptional strength-to-weight ratio; electrical conductivity; fatigue resistance | Sporting goods, UAV parts, electronic components |

| Impact-Modified | PA6, PA66 | Enhanced ductility and impact resistance; prevents cracking under sudden loads | Connectors, clips, hinges, tool housings |

| Glass Fiber + Impact Modifier | PA6, PA66, PA12 | Combines rigidity and toughness; ideal for parts that must absorb energy | Scooter frames, brackets, protective casings |

| Low-Moisture-Absorption Grades | PA6, PA66 | Improved dimensional stability; reduced warpage | Electronic connectors, sensors, precision gears |

| Recycled / Eco Compounds | PA6, PA66 | Sustainable and cost-effective; stable mechanical performance | General-purpose housings, industrial parts |

Example: In metal replacement applications, PA66 GF30 offers structural strength close to lightweight metals, while glass fiber + impact modifier compounds are ideal for components that require both rigidity and impact absorption. For applications with strict dimensional control, GF+MF or MF grades provide minimal warpage and smooth surface appearance.

4. Chemical, Thermal, and Environmental Resistance

Beyond mechanical performance, nylon compounds must also endure chemical exposure, heat, and environmental stress. The right formulation ensures long-term durability, color stability, and safety compliance under harsh operating conditions.

Here are the major compound families designed for demanding chemical or environmental environments:

| Compound Type | Reinforcement / Additives | Main Advantages | Typical Applications |

|---|---|---|---|

| PA12 | Base polymer with inherent low moisture uptake | Excellent fuel, oil, and chemical resistance; outstanding hydrolysis resistance | Fuel lines, fluid connectors, outdoor components |

| Flame-Retardant (FR) | Halogen-free or halogenated FR packages | Meets UL94 V-0 or V-2 ratings; maintains mechanical integrity under high temperature | Electrical housings, power modules, appliance parts |

| UV-Resistant / Weatherable Grades | UV stabilizers, antioxidants | Long-term color and strength retention under sunlight; prevents surface cracking | Outdoor equipment, automotive exterior parts, lighting housings |

| Heat-Stabilized Compounds | Thermal stabilizers and antioxidants | Extends service life under continuous heat or temperature cycling | Engine covers, fan blades, structural components near heat sources |

These advanced protection systems extend nylon’s reliability in demanding environments — from under-the-hood components to outdoor equipment exposed to constant UV and moisture.

Design note: When selecting materials for harsh environments, consider not only chemical compatibility but also the combined impact of UV exposure, humidity, and thermal cycling. A properly stabilized nylon compound can maintain strength and appearance for years under these conditions.

5. Processing and Cost Efficiency

Even the most advanced material must also be practical to process. A nylon compound's success in real-world production depends not only on its mechanical and chemical properties but also on how it performs during molding, cooling, and mass production cycles.

Balancing Flow, Crystallinity, and Cycle Time

Among engineering plastics, PA6 remains one of the most efficient materials to process. It offers excellent melt flow, shorter cycle times, and high moldability — ideal for complex geometries or thin-wall parts. Its great mechanical strength with relatively low processing temperature also reduces energy consumption and enables high-volume manufacturing with consistent surface finish.

PA66, in contrast, provides higher crystallinity and better thermal performance but requires tighter process control — typically higher mold temperatures and longer cooling times. When properly optimized, PA66 produces components with greater dimensional precision and reduced post-shrinkage, which is essential in structural or load-bearing designs.

📌Check out the thorough comparison of PA6 vs PA66, PA6 vs PA12 & PA66 vs PA12

Cost–Performance Optimization

Optimizing cost isn't about lowering resin price — it's about improving total manufacturing efficiency.

Key factors influencing cost-effectiveness:

- Processing efficiency: Compounds that fill molds faster and require less rework reduce cycle time and energy usage.

- Material tuning: Adjusting fiber length, filler ratio, or impact modifier package can reach target performance without overspecifying the grade.

- Process stability: Compounds with stable viscosity, low moisture sensitivity, surface finish, and predictable shrinkage minimize scrap and downtime.

- Sustainability: Recycled or eco-grade nylons can cut raw material cost while meeting environmental and corporate goals.

Expert insight: Considering molding temperature, tool wear, and cycle duration often reveals that a technically optimized compound can achieve 10–20% lower total cost without compromising performance.

While theoretical comparisons are useful, the real value of nylon compounding lies in how custom-engineered formulations solve practical challenges — replacing costly or difficult-to-process materials while maintaining performance. The following two case studies illustrate how tailored compounds achieved measurable efficiency and performance gains.

Case Study 1: Replacing PPS GF40 with a Low-Moisture Nylon Compound

A manufacturer needed an alternative to PPS GF40, which offered excellent stability but was expensive and required very high processing temperatures.

By developing a low-moisture-absorption nylon compound, our team achieved:

- Similar mechanical strength and dimensional precision,

- Easier processing at lower melt temperatures,

- Shorter cycle times and reduced mold wear.

This formulation delivered consistent performance with lower total production cost, proving that smart compounding can outperform premium polymers in targeted applications.

Case Study 2: Replacing PA12 with an Impact-Modified PA6 Compound

Another client producing sports equipment sought a more cost-efficient alternative to PA12. Through a custom impact-modified PA6 compound, we achieved:

- Comparable impact strength and flexibility,

- High fatigue resistance and long-term impact durability under repeated loading,

- Improved molding efficiency with faster cycle turnaround.

The result was a durable, production-friendly, and economically optimized solution — tailored to fit existing tooling and equipment without the need for redesign.

Takeaway: True processing efficiency goes beyond cycle speed — it's about designing nylon compounds that integrate seamlessly with your equipment, tooling, and cost structure. With decades of formulation experience and data-driven development, All Around Compounding helps manufacturers reach optimal balance between performance, productivity, and price stability.

Emerging Trends in Nylon Compounding

The nylon compounding field is evolving rapidly, driven by sustainability, performance, and new design requirements.

Here are the top trends shaping the market:

- Hybrid Reinforcements – Combining glass fiber with mineral fillers for enhanced stiffness and dimensional control.

- Low-Moisture-Absorption Compounds – Especially for electronic housings and precision mechanical parts in humid climates.

- Recycled Nylon – High-quality recycled PA materials can now match virgin-grade performance, supporting sustainability goals.

- Metal Replacement Applications – High-glass-fiber (up to 60%) and long-fiber PA compounds are replacing aluminum and steel components in structural applications.

These innovations make nylon more than just nylon — a platform for engineered performance across industries.

Selecting the right nylon compound isn't just about material type — it's about understanding performance, environment, and processing together.

By focusing on the five key factors above, engineers and procurement teams can make data-driven choices that reduce risk and extend product life.

Final Recommendation

Selecting the right nylon compound isn't just about material type — it's about understanding performance, environment, and processing together. By focusing on the five key factors above, engineers and procurement teams can make data-driven choices that reduce risk and extend product life.

Tailored Nylon Compounding Solutions — Engineered by All Around Compounding

Selecting the right nylon compound is where material science meets practical engineering. At All Around Compounding, we provide tailored nylon compounds for industries all around the world — backed not just by decades of expertise, but also by continuous progress backed by data.

Whether you're optimizing for impact resistance, dimensional stability, or metal replacement, our team can help you find the right formulation.

👉 Contact us to learn how our nylon compound solutions can enhance your next project.