In today's rapidly evolving industrial landscape, engineering plastics have emerged as pivotal materials, offering a blend of strength, versatility, and resilience. Unlike commodity plastics, these high-performance polymers are tailored for demanding applications across sectors like automotive, aerospace, electronics, and medical devices.

What Are Engineering Plastics?

Engineering plastics are a category of thermoplastics known for their superior mechanical and thermal properties. They offer enhanced durability, chemical resistance, and dimensional stability, making them ideal for applications where traditional materials might falter.

Common Types of Engineering Plastics

Several engineering plastics have become mainstays in manufacturing due to their unique properties:

Polyamide (Nylon, PA):

Known for its toughness and wear resistance, commonly used in gears and bearings.

Polycarbonate (PC):

Offers high impact resistance and optical clarity, ideal for safety glasses and electronic housings.

Polyoxymethylene (POM or Acetal):

Exhibits low friction and excellent dimensional stability, suitable for precision parts.

Polybutylene Terephthalate (PBT):

A semi-crystalline thermoplastic with excellent electrical insulation, dimensional stability, and resistance to chemicals and UV exposure. Common in automotive connectors and electronic housings.

Polyethylene Terephthalate (PET):

Known for good mechanical strength and dimensional stability. Used in precision mechanical parts, electronics, and industrial applications where chemical resistance is important.

Key Properties of Engineering Plastics

Engineering plastics are distinguished by a combination of attributes that make them indispensable in various industries:

- Mechanical Strength: High tensile and impact strength allow them to withstand significant loads and stresses.

- Thermal Resistance: Capable of operating at elevated temperatures without deformation.

- Chemical Resistance: Resistant to a wide range of chemicals, making them ideal for harsh environments.

- Dimensional Stability: Maintain their shape and size over time, even under varying environmental conditions.

- Electrical Insulation: Excellent dielectric properties make them suitable for electrical and electronic applications.

👉 These properties enable engineering plastics to replace traditional materials like metals and ceramics in many applications, offering benefits such as weight reduction, corrosion resistance, and design flexibility. For more insights, see how engineers are selecting plastics for metal replacement to improve performance and reduce costs in automotive and industrial applications.

How Are Plastics Categorized?

The performance and categorization of plastics are influenced by their molecular characteristics. One important factor is molecular weight —the length and complexity of polymer chains. Generally, higher molecular weight results in enhanced strength, toughness, and thermal resistance.

Closely related to this is the melting point of the plastic. As the molecular weight increases, the melting temperature tends to rise as well, particularly in semi-crystalline plastics. This is because longer polymer chains require more energy to break their intermolecular forces, which also contributes to improved heat stability.

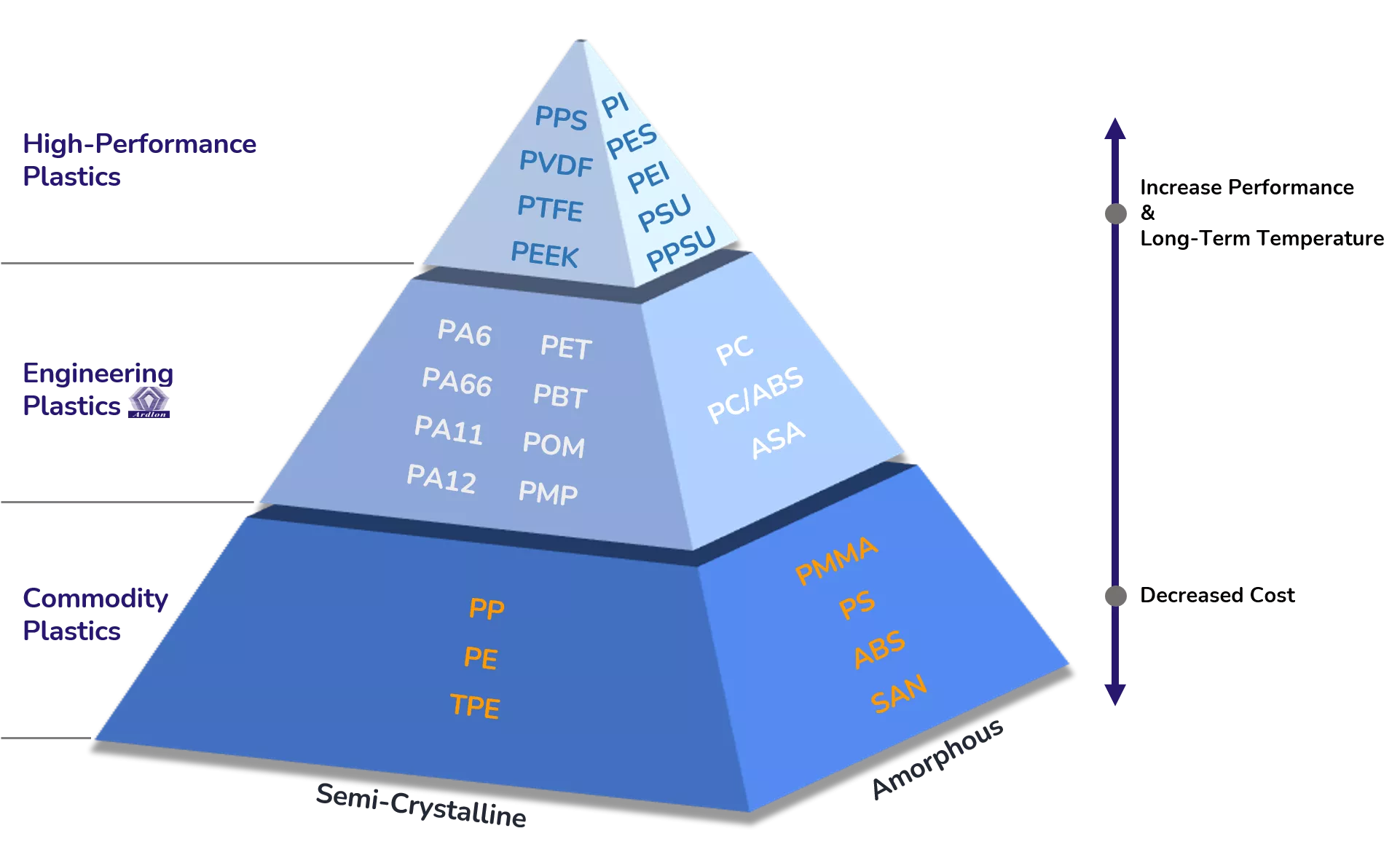

The Plastic Performance Pyramid: Categorizing Plastics by Performance

A helpful way to understand their classification is through the Plastic Performance Pyramid, which organizes plastics based on their performance characteristics and application areas:

- Commodity Plastics: Found at the base, these are used in high-volume, low-cost applications.

- Engineering Plastics: Occupying the middle tier, they offer a balance between performance and cost, suitable for more demanding applications.

- High-Performance Plastics: At the apex, these materials are designed for extreme conditions, offering exceptional thermal and chemical resistance.

This pyramid also differentiates between amorphous and semi-crystalline structures, which influence properties like transparency, toughness, long-term temperature, cost and processability.

Comparison of Commodity, Engineering, and High-Performance Plastics

To better understand the differences between various plastic categories, the following comparison highlights their key characteristics.

|

Properties |

Commodity Plastics | Engineering Plastics | High-Performance Plastics |

| Plastic Types | PE, PP, PVC, PS, ABS, etc. | PA, PC, POM, PBT, PET, etc. | PEEK, PPS, LCP, PEI, PVDF, etc. |

| Molecular Weight (g/mol) | 100,000–300,000 | 200,000–500,000 | 500,000–1,000,000+ |

| Mechanical Strength (MPa) | Moderate | High | Very High |

| Thermal Resistance | Low | Moderate | High |

| Chemical Resistance | Low | Moderate | Excellent |

| Processability | Excellent | Good | Difficult to process |

| Cost (Relative) | Low | Medium | Very High |

| Typical Applications | Packaging, household goods | Automotive, electronics, appliances | Aerospace, medical, high-temperature components |

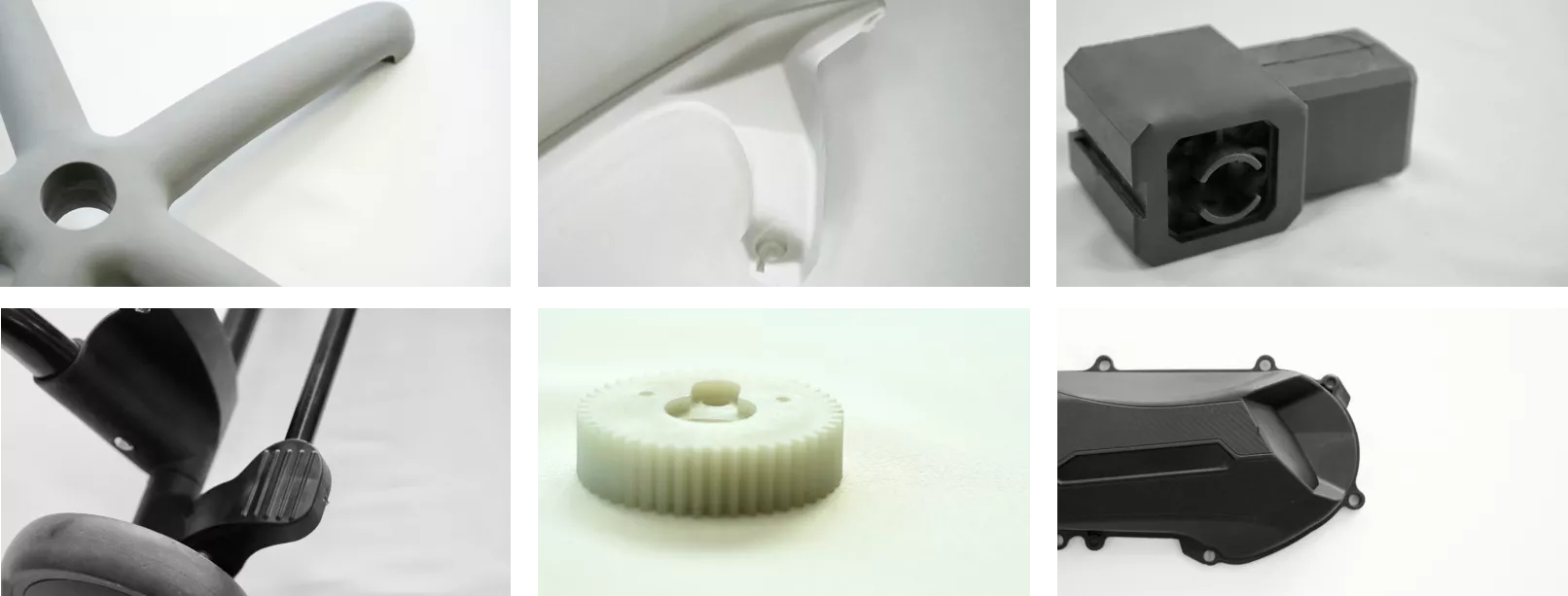

Applications Across Industries

The versatility of engineering plastics allows them to be utilized in a multitude of industries:

- Automotive: Used in components like gears, bearings, and housings to reduce weight and improve fuel efficiency.

- Aerospace: Applied in interior components and structural elements where weight savings are critical.

-

Electronics: Employed in connectors, insulators, and casings due to their electrical insulating properties.

- Medical Devices: Utilized in surgical instruments and implants for their biocompatibility and sterilization resistance.

- Industrial Machinery: Implemented in wear-resistant parts and components exposed to harsh chemicals.

Their adaptability and performance make engineering plastics a preferred choice in applications where traditional materials may fall short.

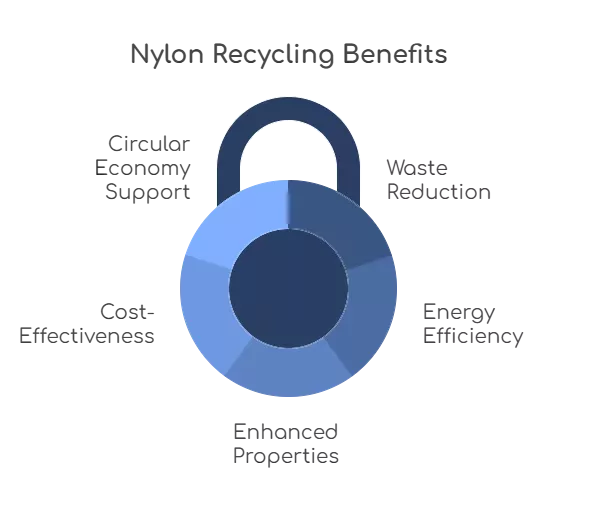

Environmental Considerations

As sustainability becomes increasingly important, engineering plastics are being developed with environmental considerations in mind:

- Recyclability: Many engineering plastics can be recycled, reducing environmental impact. One notable example is the growing use of Recycled Nylon in automotive and textile applications, which combines high performance with environmental responsibility.

- Bioplastics: Research into bio-based engineering plastics aims to create materials with similar performance characteristics derived from renewable resources.

- Lightweighting: Replacing heavier materials with engineering plastics contributes to energy savings, particularly in transportation applications.

These efforts align with global initiatives to reduce carbon footprints and promote sustainable manufacturing practices. Unlike disposable plastics often associated with pollution, nylon-based engineering plastics can be formulated for recyclability, longevity, and environmental responsibility

FAQ About Engineering Plastics

What defines an engineering plastic compared to a commodity plastic?

Engineering plastics exhibit significantly higher mechanical strength, thermal resistance, and dimensional stability than commodity plastics such as polyethylene (PE) or polypropylene (PP). They are designed for structural applications that demand long-term performance and resistance to heat, wear, and chemicals. Engineering plastics tend to have higher melting point, processing temperature and long-term temperature than commodity plastics.

How do engineering plastics compare to metals?

Although metals typically offer higher strength and stiffness, certain engineering plastics—especially those reinforced with glass fibers or aromatic structures—can replace metal parts in applications requiring lightweighting, corrosion resistance, and design flexibility. They also allow for complex geometries via injection molding, which is not possible with metals.

What are high-performance plastics and how are they different?

High-performance plastics represent the top tier of polymer materials. They maintain mechanical integrity under continuous service temperatures exceeding 150°C, and exhibit exceptional chemical and wear resistance. Materials like PEEK, PPS, PES and LCP are commonly used in aerospace, semiconductor, and medical applications where engineering plastics may fail.

Are engineering plastics suitable for long-term durability?

Yes. Many engineering plastics demonstrate excellent creep resistance, fatigue strength, and UV/weathering performance. When properly selected and processed, they can withstand 10–20 years or more in service, especially in automotive and industrial environments.

Our Experience with Engineering Plastics

At All Around Compounding (All Around Polymer Co., Ltd.), we specialize in the development and supply of a wide range of nylon-based engineering plastics, tailored to meet diverse industrial requirements. With over a decade of compounding expertise, we deliver custom formulations designed to optimize strength, weight, cost, and resistance properties based on specific project needs.

We currently offer:

-

PA6 and PA66 compounds – Including Glass fiber reinforced Nylon 6 and Glass fiber reinforced Nylon 66 grades, as well as mineral-filled variations, to improve the mechanical properties of PA6 and PA66. These materials are ideal for structural and high-performance engineering applications, offering enhanced strength and thermal resistance.

👉Check the detailed comparison of PA6 vs PA66 for material selection. -

Impact Modified PA6 and PA66: Nylon blends with POE (Polyolefin Elastomer) are designed to enhance toughness and low-temperature impact performance. Our Impact-modified Nylon 6 is especially effective in structural components that require both rigidity and ductility, while Impact-modified Nylon 66 offers superior thermal stability and is ideal for applications subjected to long-term heat exposure or mechanical stress.

👉Learn more about how Impact Modifiers Affect Nylon in Durability and Flexibility -

Low-moisture-absorption nylons: Designed to maintain dimensional stability and performance in humid or outdoor environments.

-

PBT and PET compounds: Designed for applications that demand excellent dimensional stability, electrical insulation, and resistance to chemicals. PBT is widely used in connectors and electronics, while PET performs well in precision parts and industrial components.

-

Specialty nylon blends: Such as PA with PPO, PA with EPDM, or PA modified with flame retardants, UV stabilizers, and other functional additives to fit in our client's customized requirements.

These materials are developed to support metal replacement, reduce overall system weight, and enhance performance in automotive, electrical, appliance, and industrial sectors. All formulations are backed by internal testing data, material traceability, and the ability to customize for specific end-use conditions.

Whether you're looking to reduce part weight or warpage, improve durability, or enhance processability, our team is ready to support your development goals with reliable, data-driven nylon compounding expertise. Looking for a specific nylon grade or compounding solution? Contact our engineering team today or browse our full nylon product lineup.

Conclusion

Engineering plastics have become indispensable in modern manufacturing, offering a combination of strength, durability, and versatility that meets the demands of various high-performance applications. As technology advances, the development and utilization of these materials are expected to grow, further solidifying their role in shaping the future of engineering and design.

If your project requires materials that deliver superior mechanical strength, thermal resistance, and long-term durability, engineering plastics offer a proven solution over conventional alternatives. Explore our comprehensive range of nylon-based compounds or contact our technical team for expert support in selecting the most suitable material for your application.