BSGM12

- PA6 60% GF/MF

- Reinforced with 60% Glass Fiber and Mineral Fillers

- Available in Natural, Black, or Custom Color Options

- Product Benefits: High Dimensional Stability, Low Moisture Absorption, Good-looking Surface

- Certificate: RoHS, REACH

- Scroll down to download PDF version

60% Glass Fiber and Mineral Filled Nylon 6 (PA6-(GF+MD)60)

Product Overview

60% Glass Fiber and Mineral Filled Nylon 6 (PA6-(GF+MD)60) offers unmatched rigidity and thermal performance. This material is specifically engineered for applications requiring high mechanical strength, superior dimensional stability, and excellent creep resistance under extreme conditions.

The 60% reinforcement ensures optimal performance in structural and high-stress environments, making it ideal for advanced industrial and engineering applications.

Technical Specifications

-

Material: Nylon 6 (Polyamide 6)

-

Reinforcement: 60% Glass Fiber and Mineral Fillers

-

Tensile Strength: 195 MPa

-

Elongation at Break: 2%

-

Impact Strength (23°C): 80 kJ/m²

-

Specific Gravity/Density: 1.67 g/cm³

-

Melting Point: 230°C

-

Colors: Natural, Black, or Custom Colors

Application Scenarios

60% Glass Fiber and Mineral Filled Nylon 6 is designed for heavy-duty industrial and engineering use:

-

Automotive Components: Chassis components, structural reinforcements, and engine brackets.

-

Infrastructure: High-load-bearing construction tools and heat-resistant panels.

-

Renewable Energy: Wind turbine components and solar panel mounting systems.

-

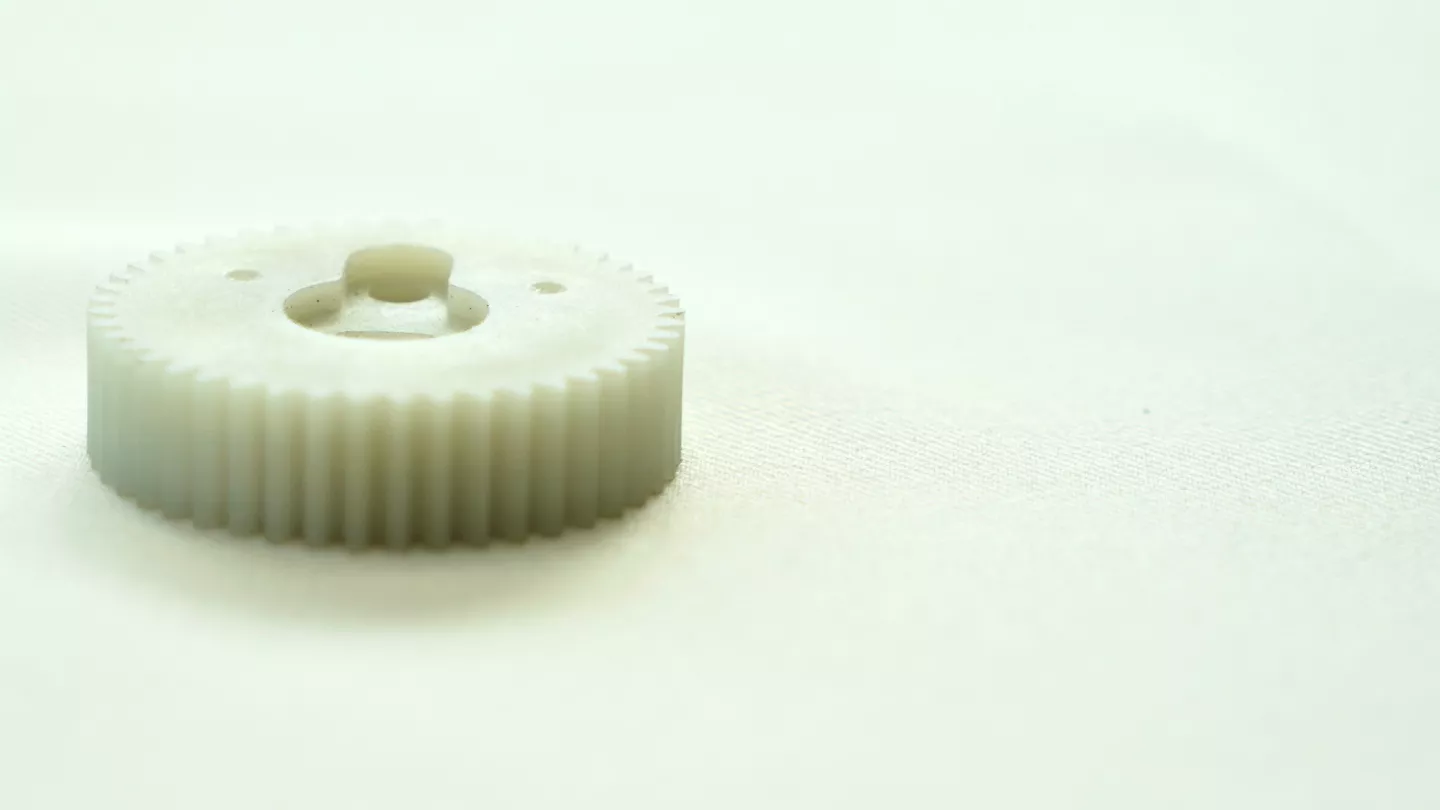

Industrial Applications: Gear wheels, conveyor belts, and precision machinery parts.

-

Metal Replacement Component: Load-bearing parts and shock-resistant housings for mining equipment.

Comparison with Other Glass Fiber and Mineral Filled Nylon Products

PA6-(GF+MD)60 |

PA6-(GF+MD)50 |

PA6-(GF+MD)40 |

PA6-(GF+MD)30 |

|

| Tensile Strength | 195 MPa | 180 MPa | 163 MPa | 145 MPa |

| Elongation at Break | 2% | 2.2% | 3% | 3.5% |

| Impact Strength | 80 kJ/m² | 77 kJ/m² | 73 kJ/m² | 70 kJ/m² |

| Density | 1.67 g/cm³ | 1.56 g/cm³ | 1.46 g/cm³ | 1.37 g/cm³ |

Applications

60% Glass Fiber and Mineral Filled Nylon 6 is commonly used in automotive, infrastructure, renewable energy, industrial, and heavy machinery applications requiring exceptional rigidity, strength, and dimensional stability.

Technical Properties

Swipe Right to View Full Details

| Properties | Test Method | Units | Conditions | Value |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | Dry | 1.67 |

| Tensile strength at break | ISO 527 (50mm/min) |

Mpa | Dry Cond. |

195 160 |

| Elongation at break | ISO 527 (50mm/min) |

% | Dry Cond. |

2 2.2 |

| Impact strength | ISO 180-1C Charpy,23℃ |

Kj/㎡ | Dry Cond. |

80 80 |

| Impact strength | ISO 180-1C Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

72 75 |

| Notched impact strength | ISO 180-1A Charpy,23℃ |

Kj/㎡ | Dry Cond. |

14 14 |

| Notched impact strength | ISO 180-1A Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

14 13 |

| Melting point | ISO 3146C DSC | ℃ | Dry | 230 |

Download file