Warpage and shrinkage are common challenges in nylon injection molding that can significantly affect dimensional accuracy, assembly fit, and appearance. Understanding what causes these dimensional changes—and how to prevent them—requires a complete approach that includes material formulation, molding process optimization, and mold/tool design. In practice, engineers often start by confirming the nylon shrinkage value of a target grade and then validating how processing and geometry amplify (or stabilize) real-world deformation.

This guide explains the main causes of warpage and shrinkage in nylon compounds and provides practical solutions categorized into four areas: material formulation, process optimization, mold & part design, and post-processing/environmental control.

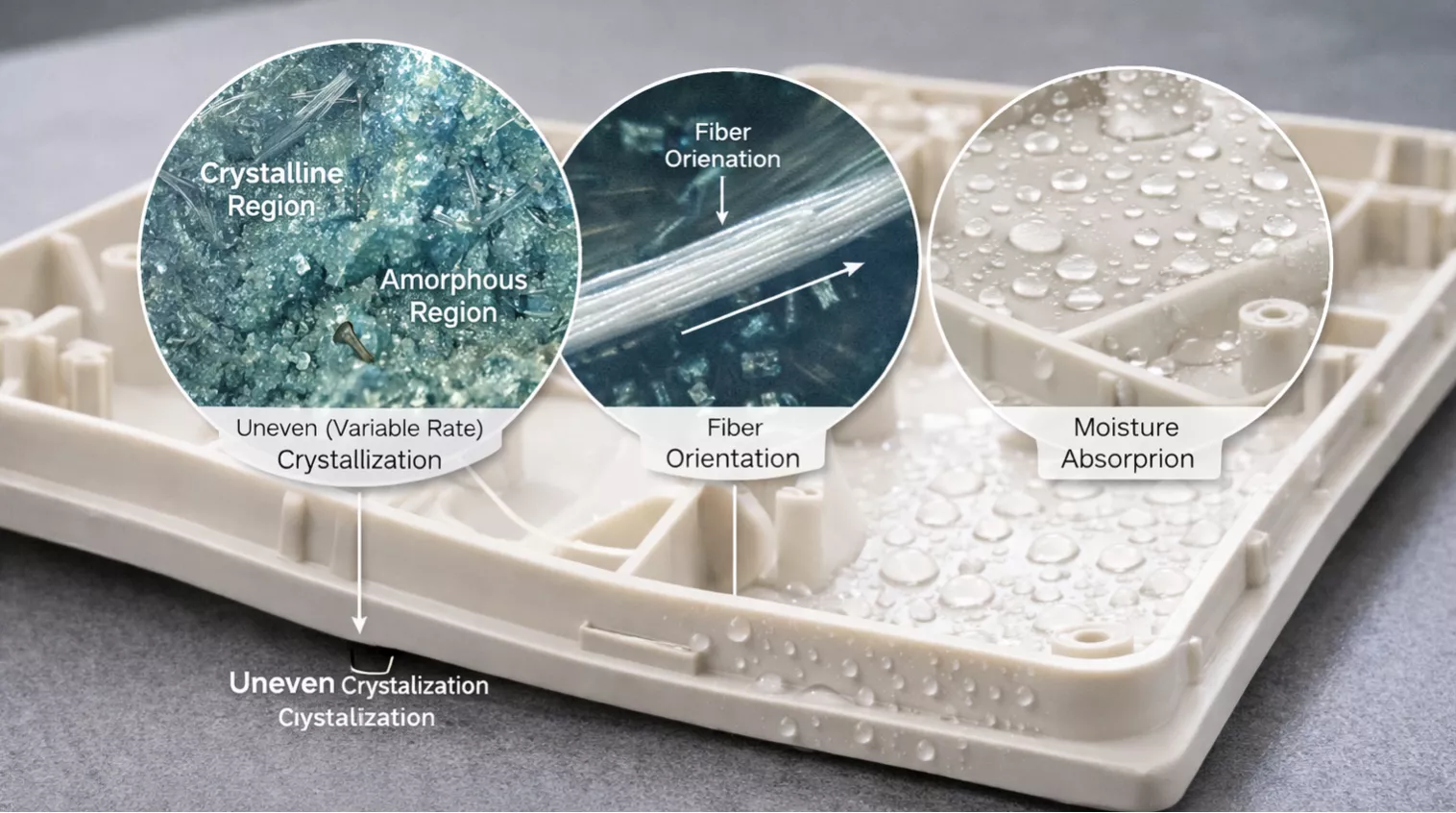

Root Causes of Warpage and Shrinkage in Nylon Compounds

Warpage and shrinkage occur due to uneven contraction of the material during or after molding. These dimensional changes can be traced to four major categories of causes:

| Category | Key Root Causes | Focus Area for Solution |

|---|---|---|

| A. Material-Related Factors | Uneven crystallization, fiber orientation, moisture absorption | Material Formula & Compound Design |

| B. Process-Related Factors | Mold temperature imbalance, residual stress, packing/holding pressure | Injection Molding Process Optimization |

| C. Design-Related Factors | Uneven wall thickness, gate placement, insufficient venting/ejection | Mold and Part Design |

| D. Environmental Factors | Moisture conditioning, storage environment, annealing | Post-Processing & Environmental Control |

A. PA6/PA66 Shrinkage: Material Formulation and Compound Design

Typical causes: uneven crystallization, fiber orientation, and moisture absorption. If you are troubleshooting dimensional drift, begin by confirming the baseline nylon shrinkage value of the resin/compound and whether anisotropy is expected.

1) Uneven Crystallization

Nylon is a semi-crystalline polymer, and its molding shrinkage is directly influenced by how crystals form and grow during cooling. If some regions crystallize faster or more fully than others, they contract unevenly—creating internal stress and visible warpage.

Clarification: Higher crystallinity generally gives nylon a more ordered molecular structure with fewer amorphous regions. This improves rigidity and reduces the number of sites available for water absorption, supporting long-term dimensional stability in humid environments. However, higher crystallinity can also increase initial molding shrinkage, because crystalline regions pack more tightly as they solidify. Therefore, controlling crystallization rate and uniformity is critical.

📌 Recommended Reading: Types of Nylon (Polyamide): Everything You Need to Know About PA6, PA66, and Beyond

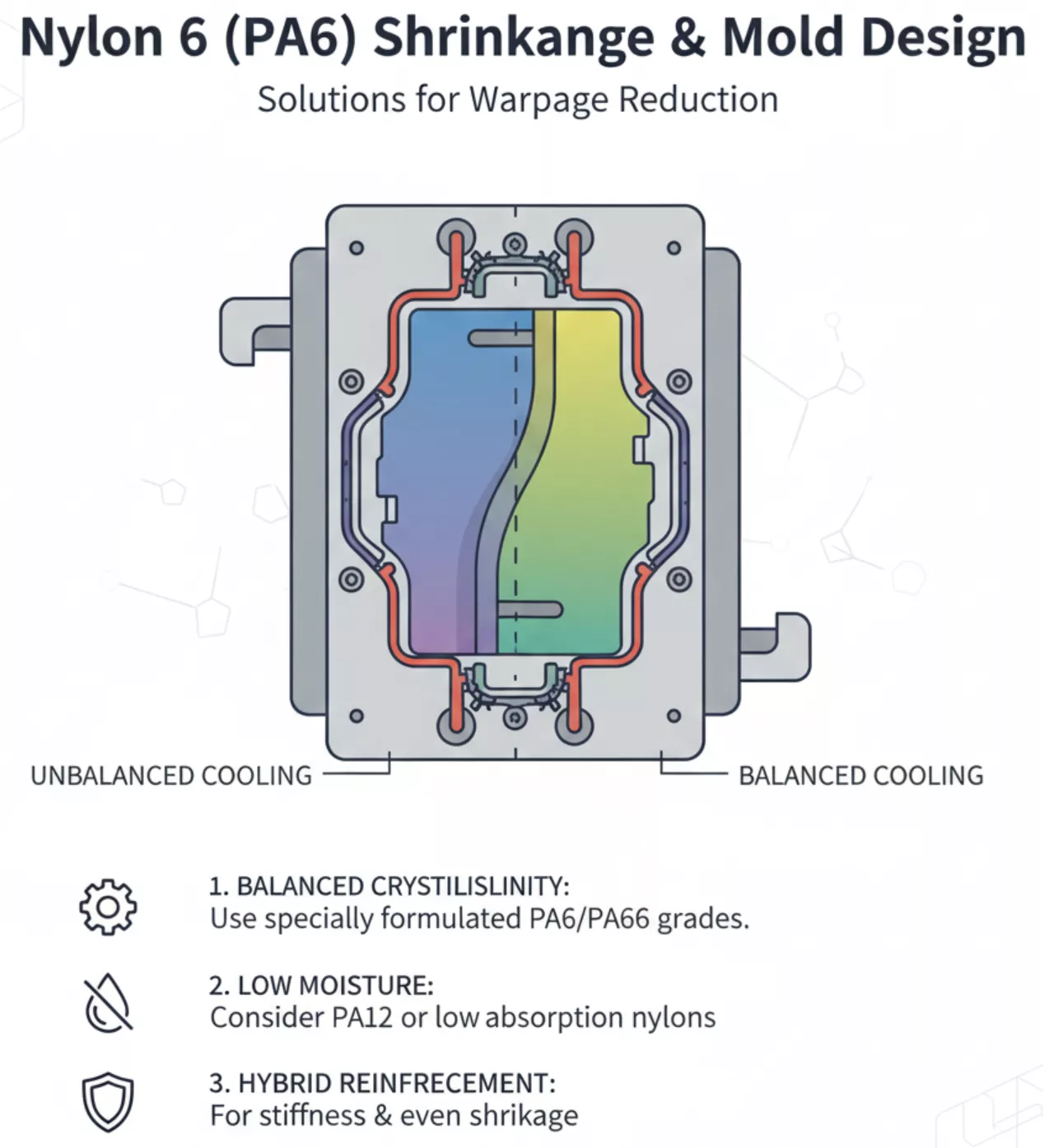

Nylon 6 (PA6) Shrinkage Value and Mold Design

Nylon 6 shrinkage value is a key parameter for mold design. For unfilled Nylon 6, the typical mold shrinkage rate ranges from 0.8% to 1.2%. This is generally lower than PA66 due to PA6’s moderate crystallinity. To reduce warpage in PA6 parts, the goal is to achieve uniform crystallization across the part and avoid localized hot spots or cooling imbalance.

Solutions:

- Select materials with balanced crystallization behavior—such as specially formulated PA6 or PA66 grades—when dimensional precision is critical.

- For humid or long-term service environments, consider PA66 or low-moisture-absorption nylon systems (e.g., PA12 or customized low-moisture grades) to reduce post-molding deformation.

- Consider hybrid-reinforced grades that provide stiffness while managing shrinkage more evenly.

2) Fiber Orientation & Anisotropic Shrinkage in Reinforced Nylon

Glass fiber reinforcement improves mechanical strength but also introduces anisotropic shrinkage—meaning shrinkage differs between flow and transverse directions. In real production molds, fiber orientation often becomes the dominant driver of directional shrinkage even when crystallinity and moisture are well controlled.

Solutions:

- Combine glass fiber with mineral fillers (GF+MF) to balance stiffness and isotropy.

- Control fiber orientation through gate design, injection speed, and flow path—not by relying on fiber length alone.

- For demanding dimensional precision, use formulations designed for balanced flow and lower anisotropy (including long-fiber solutions where applicable).

📌 Recommended Reading: Complete Guide to Long Fiber Reinforced Nylon: Grades, Properties, and Applications

3) Moisture Absorption and Dimensional Stability in Nylon Compounds

Nylon naturally absorbs moisture, which acts as a plasticizer—reducing stiffness and causing dimensional expansion after molding. Excess moisture during processing can also create bubbles, poor surface finish, and unstable shrinkage behavior.

Solutions:

- Before molding: Maintain strict drying control to stabilize viscosity and prevent hydrolysis. Typical drying conditions are 130 °C for 3–4 hours for PA6/PA66 compounds (depending on storage and humidity).

- Material selection: Use low-moisture-absorption compounds to limit water uptake and maintain dimensional stability in humid environments.

- After molding: Apply controlled moisture conditioning when dimensional stabilization is required prior to assembly or coating.

📌 Recommended Reading: Glass Filled Nylon Injection Molding: Processing Guide for PA6 & PA66 GF Materials

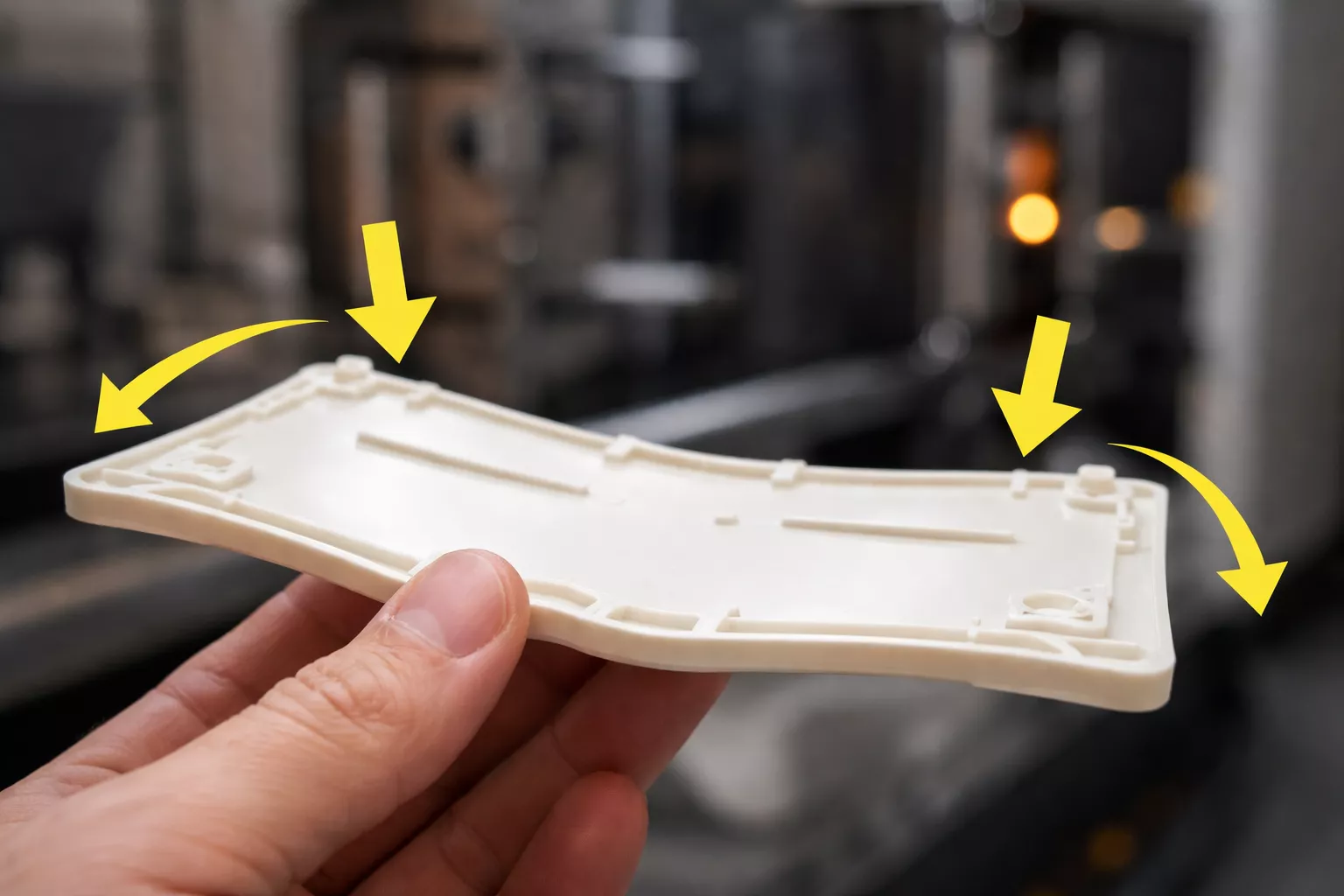

B. Injection Molding Process Optimization for Nylon Warpage Control

Typical causes: mold temperature imbalance, residual stress, and improper packing/holding pressure. Even small temperature differentials between core and cavity surfaces can produce measurable warpage in PA6 and PA66.

1) Mold Temperature Imbalance

Different cooling rates across the cavity create uneven shrinkage and internal stress release.

- Maintain uniform mold temperature, typically 80–110 °C for PA6/PA66.

- Balance cooling channel layout and monitor temperature across zones.

- Avoid large mold temperature differences between cavities.

2) Residual Stress from Packing Pressure

Over-packing or insufficient holding can trap internal stress that releases after demolding, causing distortion.

- Optimize holding pressure/time based on part thickness.

- Use stable melt temperatures (typical: 250–270 °C for PA6; 280–300 °C for PA66).

- Implement gradual pressure decay instead of abrupt cut-off.

3) Inconsistent Drying

Moisture in resin causes unstable viscosity and uneven crystallization.

- Dry PA6/PA66 compounds at 130 °C for 3–4 hours before molding.

- Store dried material in sealed containers to prevent reabsorption.

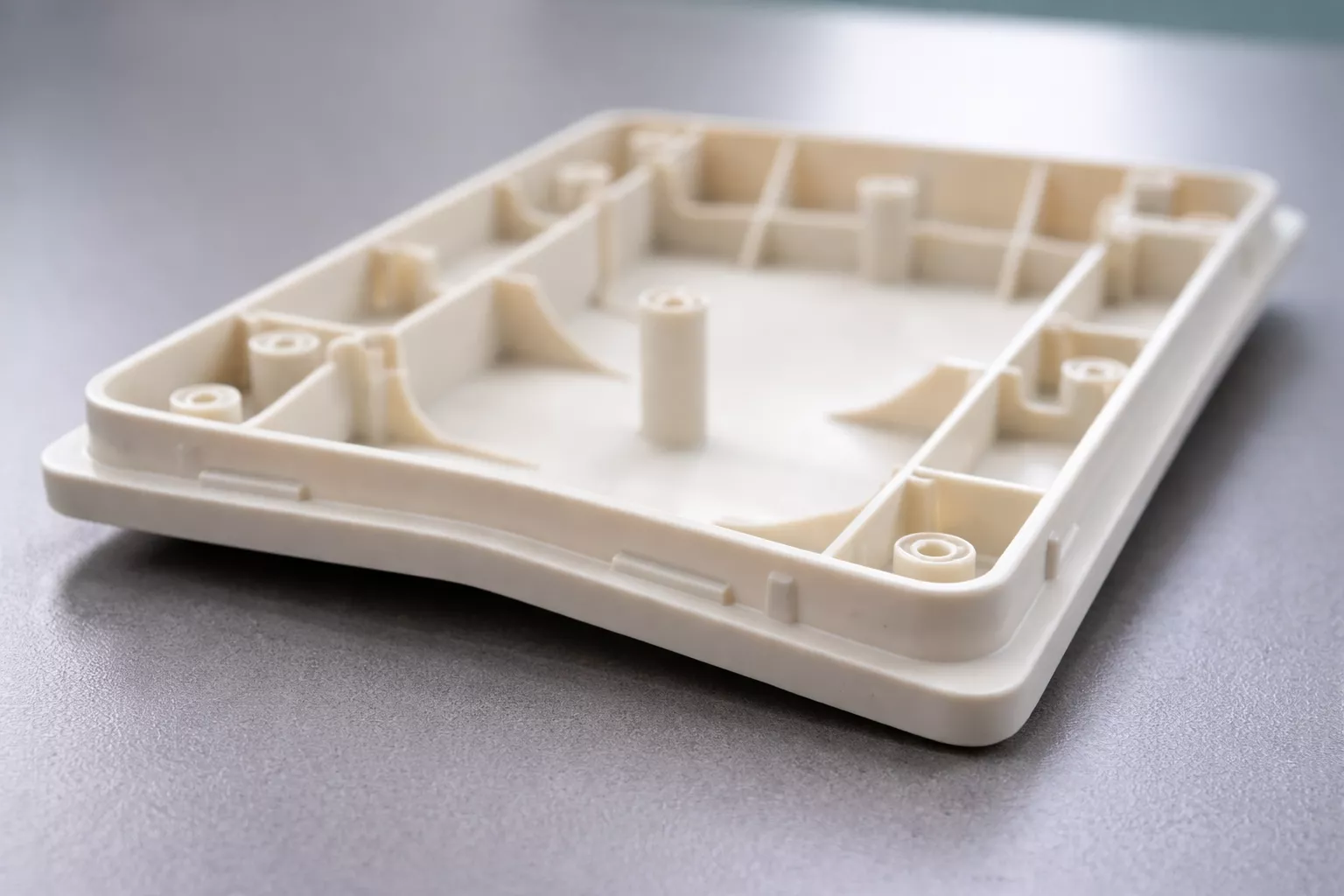

C. Mold & Part Design Solutions to Minimize Nylon Shrinkage

Typical causes: uneven wall thickness, poor gate design, insufficient venting, and asymmetric ejection.

1) Uneven Wall Thickness

Thicker sections cool slower than thinner ones, creating differential shrinkage.

- Maintain uniform wall thickness and smooth transitions.

- Avoid abrupt thickness changes; use gradual tapers or fillets.

2) Gate Location and Flow Path

Improper gate placement causes unbalanced flow, directional fiber orientation, and stress concentration.

- Use centrally located or multiple gates to distribute flow evenly.

- For long/flat parts, consider fan gates or diaphragm gates.

- Use flow simulation (Moldflow, Moldex3D) to predict shrinkage direction and fiber orientation.

3) Venting and Ejection

Poor venting or asymmetric ejection can deform parts during cooling and ejection.

- Design adequate venting at cavity ends to release trapped air.

- Ensure balanced ejector pin layout to prevent localized deformation.

D. Post-Molding Treatments: Annealing and Moisture Conditioning

Typical causes: dimensional changes after molding due to stress relaxation or humidity exposure.

1) Annealing Treatment to Release Nylon Residual Stress

- Apply annealing to release stress and improve dimensional stability.

- Typical annealing: 80–100 °C for 2–4 hours (depends on thickness and geometry).

2) Controlled Moisture Conditioning for Dimensional Stability

After molding, nylon parts are often very dry and may deform once they begin absorbing moisture naturally. Moisture conditioning helps the polymer reach equilibrium moisture under controlled conditions before assembly.

- Humidity chamber: controlled environment (e.g., 23 °C / 50% RH).

- Warm-water immersion: 70–80 °C for limited time, then surface drying.

- Steam conditioning: fast but less precise; used for thick/high-stress parts.

3) Long-Term Storage and Handling

- Store parts in sealed containers or humidity-controlled rooms.

- Avoid prolonged exposure to high humidity before coating or assembly.

FAQs

1) What is the typical shrinkage rate of PA6 and PA66?

Nylon shrinkage value (Polyamide) typically ranges from 0.8% to 1.6% for unfilled grades, and is reduced to roughly 0.2% to 0.6% when 30% glass fiber (GF30) is added.

| Material | Filler Type | Typical Mold Shrinkage (%) | Relative Crystallinity | Dimensional Stability | Remarks |

|---|---|---|---|---|---|

| PA6 | Unfilled | 0.8 – 1.2 | Moderate | Moderate | Lower crystallinity reduces molding shrinkage but may increase long-term moisture-driven drift. |

| PA66 | Unfilled | 1.1 – 1.6 | High | High | Higher crystallinity increases initial shrinkage but improves long-term stability in humid environments. |

| PA6 GF30 | 30% Glass Fiber | 0.2 – 0.5 | Moderate | High | GF lowers shrinkage and increases stiffness; anisotropy still depends on fiber orientation. |

| PA66 GF30 | 30% Glass Fiber | 0.3 – 0.6 | High | Very High | High rigidity and heat resistance; suited for high-precision components. |

| PA66 GF50 | 50% Glass Fiber | 0.07 – 0.1 | High | Excellent | Very high stiffness and stability for structural/metal-replacement parts. |

| PA6 (GF+MD)30 | Hybrid Glass + Mineral | 0.2 – 0.4 | Moderate | Excellent | Hybrid fillers reduce anisotropy and improve flatness and accuracy. |

2) How can I prevent nylon warpage during injection molding?

Use uniform mold temperature, stable drying, optimized packing/holding, and consider hybrid fillers (GF+MF) to reduce anisotropic shrinkage.

3) Which nylon has better dimensional stability, PA6 or PA66?

PA66 generally offers higher crystallinity and better long-term dimensional stability in humid environments. PA66 may show higher initial molding shrinkage than PA6, but post-molding stability is often superior.

4) What additives reduce nylon shrinkage?

Hybrid reinforcement (GF+MF/MD) improves isotropy and flatness. Nucleating agents can promote more uniform crystal growth, reducing localized stress and improving dimensional consistency.

5) Does recycled nylon show more warpage?

Recycled nylon may show more warpage due to molecular-weight reduction and wider material variation. With strong raw-material control and formulation design, dimensional stability can be improved close to virgin performance, but it may not be identical in every case.

6) How to calculate nylon shrinkage value in mm?

While shrinkage is typically given in percentage (%), the nylon shrinkage value in mm is calculated by multiplying nominal part length by the shrinkage rate:

Formula: Shrinkage (mm) = Nominal Part Length (mm) × Shrinkage Rate

Example: A 100 mm part made of unfilled PA6 with 1.0% shrinkage will shrink by 100 × 0.01 = 1.0 mm. This helps determine the mold cavity size (shrinkage allowance). When applying the nylon 6 shrinkage value in mm, the same 100 mm length at 0.3% (GF30) results in 0.3 mm shrinkage.

7) How much shrinkage is considered acceptable in nylon injection molding?

The acceptable nylon shrinkage value depends on tolerance requirements.

- Unfilled PA6 / PA66: 0.8%–1.6%

- GF30 nylon: 0.2%–0.6%

- High-stiffness grades (GF50, GF+MD): < 0.1%

In practice, engineers often assess shrinkage using the nylon shrinkage value in mm. For example, a 100 mm PA6 part at 1.0% shrinks by 1.0 mm, while the nylon 6 shrinkage value in mm for GF30 (0.3%) is only 0.3 mm. The goal is predicting and compensating shrinkage through material choice, mold design, and process control.

Key Takeaways: A Summary of Causes and Practical Solutions

Warpage and shrinkage stem from multiple, often overlapping factors. Each cause can be managed by targeting the right aspect of the system—material, process, design, and post-processing.

| Root Cause | Recommended Solution | Example Action |

|---|---|---|

| Uneven crystallization | Controlled formulation and uniform cooling | Use nucleating agents, optimize cooling rate, adjust GF ratio |

| Fiber orientation | Hybrid reinforcement and flow control | Combine GF with MF/MD, improve gate design, regulate injection speed |

| Mold temperature imbalance | Process temperature balance | Uniform mold temperature and optimized cooling channels |

| Residual stress from packing/cooling | Pressure and time optimization | Adjust holding pressure/time; gradual pressure decay |

| Moisture absorption | Material design and post-treatment | Low-moisture compounds; controlled moisture conditioning |

| Inadequate mold design | Design optimization | Improve wall-thickness transitions, gate layout, venting and ejection symmetry |

| Environmental exposure and handling | Post-processing stabilization | Annealing, conditioning, humidity-controlled storage |

Final Thoughts: Implementing a Holistic Strategy for Dimensional Stability

Warpage and shrinkage are not caused by a single factor but by the interaction between material behavior, process settings, part geometry, and environmental exposure. Achieving stable dimensions requires engineers to treat these elements as one integrated system—where the baseline nylon shrinkage value, flow-driven anisotropy, cooling balance, and moisture equilibrium collectively determine the final outcome.

A robust approach starts with compound design to control crystallization and fiber orientation, followed by disciplined process optimization to reduce residual stress. Finally, annealing, moisture conditioning, and proper storage practices help prevent long-term drift and ensure dimensional stability throughout service life.

Tailored Nylon Compounding Solutions — Engineered by All Around Compounding

At All Around Compounding, we combine formulation expertise with processing data to develop low-warpage nylon compounds tailored to specific molding conditions and performance targets—supporting stable nylon shrinkage value control from material selection to production validation.

Looking to improve dimensional stability in your next project?

👉 Contact us to discuss a customized nylon solution engineered for your tooling, process window, and performance requirements.