Polyamide (PA), more commonly known as nylon, is one of the most versatile engineering plastics used in modern industries. From fibers and films to automotive and electronic components, polyamides are available in a wide range of types—such as PA6, PA66, PA11, and PA12—each with distinct properties and application areas. Understanding these differences is essential for engineers, designers, and procurement managers to choose the right material for durability, performance, and cost efficiency.

1. What Is Nylon (Polyamide, PA)?

Before diving into the types, it's important to first understand what nylon—or polyamide (PA)—is at its core.Nylon is a synthetic polymer formed by linking repeating amide bonds through processes like condensation or ring-opening polymerization. Its robust molecular structure provides:

- High tensile strength

- Abrasion resistance

- Chemical stability

These qualities make nylon suitable for diverse forms such as fibers, molded parts, and films. Importantly, “PA” is the standard abbreviation for polyamide, and it encompasses multiple types (PA6, PA66, PA12, etc.) that differ significantly in their properties.

Learn more about Nylon6 (PA6), Nylon66 (PA66) and Nylon12 (PA12).

2. Common Types of Nylon (Polyamide)

Different PA types exist to serve different applications, from flexible fibers to heat-resistant automotive parts. The most widely used and notable types include:

Nylon 6 (PA6): Made from caprolactam; known for flexibility but higher moisture absorption.

- Nylon 6 (PA6): Made from caprolactam; known for flexibility but higher moisture absorption.

- Nylon 66 (PA66): Produced from hexamethylenediamine and adipic acid; stronger and more rigid than PA6.

- Nylon 11 (PA11): Bio-based from castor oil; offers excellent impact resistance.

- Nylon 12 (PA12): Lightweight, low moisture absorption, and chemical resistant.

- Nylon 610 / PA612: Low water absorption, stable dimensions, suited for precision parts.

- Nylon 1010: High extensibility and strong low-temperature performance.

- Nylon 46 (PA46): Outstanding heat resistance, designed for extreme mechanical loads.

For a full list of types and their applications, visit our resource on Nylon catalog.

PA Types Comparison Table

This quick reference highlights the major PA types, their defining traits, and most common applications.

| Type | Key Properties | Common Applications |

| PA6 (Nylon 6) | Tough, flexible, but absorbs more moisture | Textiles, automotive parts, films, packaging |

| PA66 (Nylon 66) | High strength, rigidity, heat resistance | Gears, engine components, industrial fasteners |

| PA11 | Bio-based, excellent impact resistance | Fuel lines, pneumatic tubing, sporting goods |

| PA12 | Lightweight, low moisture absorption | Electrical connectors, pipelines, 3D printing |

| PA610/ PA612 | Very low water absorption, high stability | Precision engineering, cable coatings |

| PA1010 | Flexible, works well in cold climates | Tubing, outdoor parts |

| PA46 | Extreme heat and stress resistance | Automotive under-the-hood parts |

Applications by PA Type

Each PA type has its own niche. Below is a summary of where different types of nylon are most commonly used:

- PA6 & PA66: General-purpose engineering plastics for automotive and industrial parts.

- PA11 & PA12: Ideal for tubing, connectors, and pipelines where chemical and moisture resistance matter.

- PA610 & PA612: Used in precision applications like cable sheathing.

- PA1010: Performs in cold environments with good flexibility.

- PA46: Chosen for high-heat automotive environments.

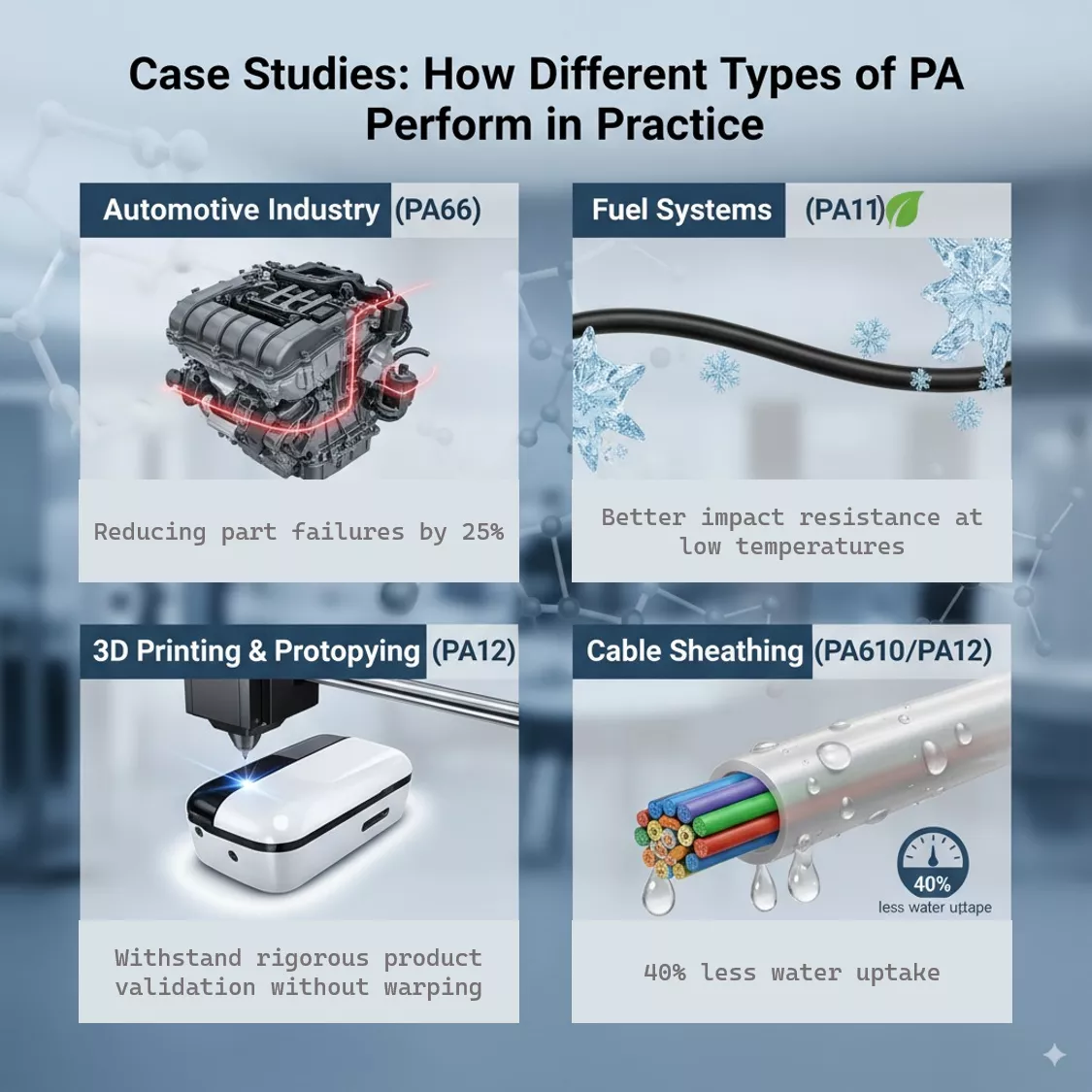

Case Studies: How Different Types of PA Perform in Practice

Practical applications show how choosing the right PA type can solve real engineering challenges:

- Automotive Industry (PA66):

A Tier-1 automotive supplier switched from PP to PA66 reinforced with 30% glass fiber for under-the-hood components. The change improved heat resistance and dimensional stability, reducing part failures by 25% in long-term engine testing.

- Fuel Systems (PA11):

In the transportation sector, bio-based PA11 is widely used in fuel lines. A European OEM selected PA11 over PA12 due to its better impact resistance at low temperatures, which extended service life in cold climates.

- 3D Printing & Prototyping (PA12):

A consumer electronics company adopted PA12 powder for selective laser sintering (SLS) in prototype casings. The material’s low moisture absorption and chemical resistance allowed the prototypes to withstand rigorous product validation without warping.

- Cable Sheathing (PA610/PA612):

A precision engineering firm chose PA612 for cable coatings in high-humidity environments. Compared to standard PA6, the material showed 40% less water uptake, ensuring long-term electrical insulation stability.

3. Classification of Nylon Polymers

Nylons are not only defined by their type numbers but also by their molecular structures.

They can be broadly classified as aliphatic, semi-aromatic, or fully aromatic, which explains performance differences in heat, strength, and chemical resistance.

| Category | Example Types | Key Traits |

| Aliphatic | PA6, PA66, PA11, PA12, PA610, PA612, PA1010, PA46 | Balanced performance, cost-effective |

| Semi-aromatic | MXD6 | Higher heat and chemical resistance |

| Fully aromatic | PPTA (e.g., Kevlar®) | Superior strength, specialty applications |

For further details on classifications and emerging trends, see Understanding the Diverse World of Nylon Polymers.

4. How Nylon Is Made

The manufacturing process for each nylon type plays a critical role in determining its performance. While all PA types share a common polymer backbone, their production methods differ significantly:

- PA6: Ring-opening polymerization of caprolactam.

- PA66: Condensation polymerization of hexamethylenediamine and adipic acid.

- PA11 & PA12: Produced from castor oil derivatives or laurolactam, with low moisture absorption.

- Other nylons (PA610, PA612, PA1010, PA46): Follow specific condensation routes to optimize strength, flexibility, or thermal stability.

These production differences explain why PA6 absorbs more water, PA12 resists chemicals better, and PA46 tolerates higher heat.For more on processing challenges and solutions, check out PA6 vs PA66: Difference & Comparison for Material Selection and PA6 vs PA12: Key Differences, Applications & Performance.

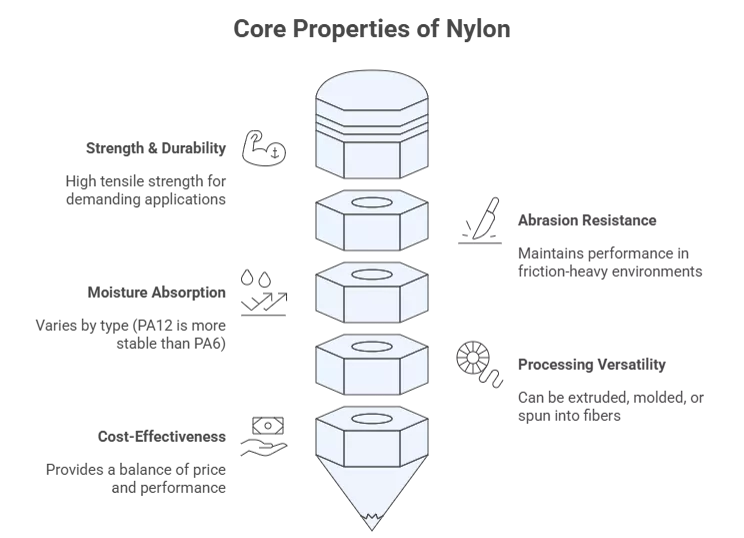

5. Key Material Properties of Nylon

Although every PA type has unique strengths, there are core properties that define the nylon family. These make PA one of the most popular choices in engineering plastics:

- Strength & Durability → High tensile strength for demanding applications.

- Abrasion Resistance → Maintains performance in friction-heavy environments.

- Moisture Absorption → Varies by type (PA12 is more stable than PA6).

- Processing Versatility → Can be extruded, molded, or spun into fibers.

- Cost-Effectiveness → Provides a balance of price and performance compared to other engineering plastics.

Nylon often provides an optimal balance of performance and affordability compared to other engineering plastics. Check out the full capabilities of PA Compounds & : The Role of Additives and Customized Solutions.

6. Enhancing Nylon Performance

Beyond selecting the right PA type, nylon can be modified to further extend its capabilities. Additives and reinforcements are frequently used to adapt nylon for specialized industrial needs:

- Impact Modifiers:

These additives significantly improve toughness and impact resistance, ensuring components can withstand harsh conditions. Learn more in Enhance Nylon Durability and Flexibility with the Right Impact Modifier. - Reinforced Composites:

Adding materials like glass fiber, carbon fiber, or mineral fillers enhances strength and dimensional stability. Discover additional benefits in Nylon Composite Materials: 6 Main Types, Advantages, and Applications.

7. Sustainability and Recycling: The Future of Nylon

As sustainability becomes a priority across industries, nylon production and recycling are also evolving.Modern approaches emphasize reducing waste, lowering emissions, and using renewable sources:

- Recycling Innovations: Chemical recycling converts nylon waste back into high-quality raw material.

- Environmental Benefits: Conserves energy, reduces emissions, and supports circular economy goals.

- Bio-Based Solutions: Options like PA11 from castor oil reduce reliance on fossil fuels

For more on how recycling is transforming the industry, visit our article Recycled Nylon: Turning Waste into Value.

Key Takeaways & How to Get Started

The diversity of PA types makes it possible to meet performance needs across a wide range of industries.By understanding each type’s properties and applications, businesses can make smarter material choices:

- PA6 & PA66 → Versatile, widely used for automotive and mechanical parts.

- PA11 & PA12 → Excellent for tubing, connectors, and chemical-resistant applications.

- PA610/612 & PA1010 → Ideal for precision engineering and outdoor conditions.

- PA46 → The go-to choice for extreme heat and mechanical stress.

Why Experience Matters in Choosing PA Types

These real-world case studies show that the right PA selection directly impacts product reliability, cost efficiency, and sustainability. From automotive to electronics, making informed decisions ensures long-term success.

Ready to choose the best PA type for your application? Contact us at info@aaccl.com to explore tailored nylon compounds and advanced polyamide solutions.