In industrial manufacturing, choosing the right material is critical to ensuring long-term reliability, reducing maintenance costs, and improving efficiency. Among engineering plastics, glass fiber reinforced Nylon 12 (PA12 GF)—especially PA12 GF30 (30% glass fiber reinforced)—has become one of the most trusted solutions for industrial components thanks to its extremely low moisture absorption, excellent dimensional stability, and superior chemical resistance.

This article explains the key advantages and limitations of PA12 GF30, compares it with PA12 GF15, PA12 GF40, PA6 GF30, and PA66 GF30, and highlights real-world applications to help engineers and procurement teams make the best material selection for harsh industrial environments.

📌 If you haven't read about PA12, check out our article What Is PA12 (Nylon 12)? Properties, Benefits, and Key Industrial Applications.

📌 If you would like to know further about the comparison of PA12 and other nylon, please read: PA6 vs PA12 or PA66 vs PA12.

What Is Nylon PA12 GF30? Key Properties and Industrial Applications

Nylon PA12 GF30 is a glass fiber reinforced version of Polyamide 12 (PA12)—a semi-crystalline thermoplastic engineered for toughness, flexibility, and resistance to chemicals and environmental stress. The addition of 30% glass fiber reinforcement significantly enhances its mechanical performance, giving it a balance of rigidity, impact resistance, and dimensional precision that pure PA12 alone cannot achieve.

👉 For technical data and formulation options, visit our PA12 GF30 Product Page.

Material Characteristics

PA12 itself is distinguished from other nylons (such as PA6 and PA66) by its longer aliphatic chain structure, which results in lower moisture absorption (<0.25%), improved weatherability, and greater flexibility. When reinforced with glass fiber, these advantages combine with higher stiffness and strength, making PA12 GF30 ideal for complex, precision-molded industrial components.

📌 If you'd like a deeper understanding of nylon types and classifications, see our guide on Types of Nylon (Polyamide): Everything You Need to Know About PA6, PA66, and Beyond.

PA12 GF30 Mechanical and Thermal Profile

- Tensile strength: 110 MPa

- Elongation at break: 5%

- Heat deflection temperature (HDT @1.8 MPa): up to 170 °C

- Notched Charpy impact: 21 kJ/m² or higher

These values reflect a material capable of withstanding both mechanical stress and temperature fluctuations without significant deformation or cracking.

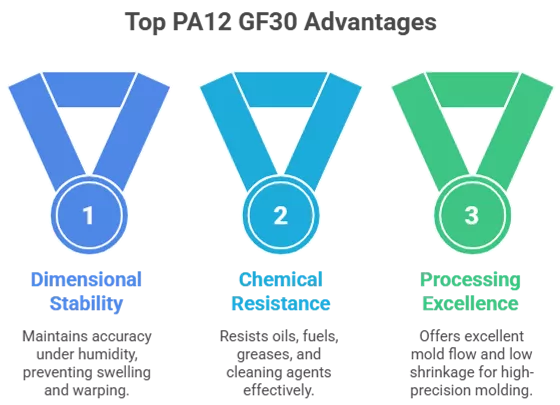

Why Engineers Choose PA12 GF30

Compared with PA6 GF30 and PA66 GF30, PA12 GF30 maintains dimensional accuracy even under humidity, allowing for stable performance in environments where other nylons would swell or warp. It also resists oils, fuels, greases, and cleaning agents—making it a preferred choice in automation systems, fluid handling modules, and outdoor control housings.

From a processing standpoint, PA12 GF30 offers excellent mold flow and low shrinkage, enabling high-precision injection molding with complex designs, thin walls, and integrated inserts. Its smooth surface finish and semi-transparent black appearance also make it suitable for sensor covers and optical housings.

📌 Learn more about how we enhance nylon's properties through customization in PA Compounds, Additives & Customization.

PA12 GF Grades: GF15 vs GF30 vs GF40

| Grade | Mechanical Behavior | Recommended Applications |

|---|---|---|

| PA12 GF15 | Moderate stiffness, retains high flexibility | Portable housings, light-duty brackets, parts requiring resilience |

| PA12 GF30 | Balanced strength, rigidity, and flowability | Mid-size enclosures, sensor bases, wire harness covers, valve components |

| PA12 GF40 | High rigidity and heat resistance | Precision gears, heavy-duty brackets, outdoor housings |

PA12 GF30 is the most versatile grade, widely adopted in industrial automation, outdoor control boxes, and sensor systems. For a deeper dive into fiber reinforcement and dimensional balance, visit PA GF & MD: Glass Fiber and Mineral Filled Nylon.

Advantages and Disadvantages of PA12 GF30

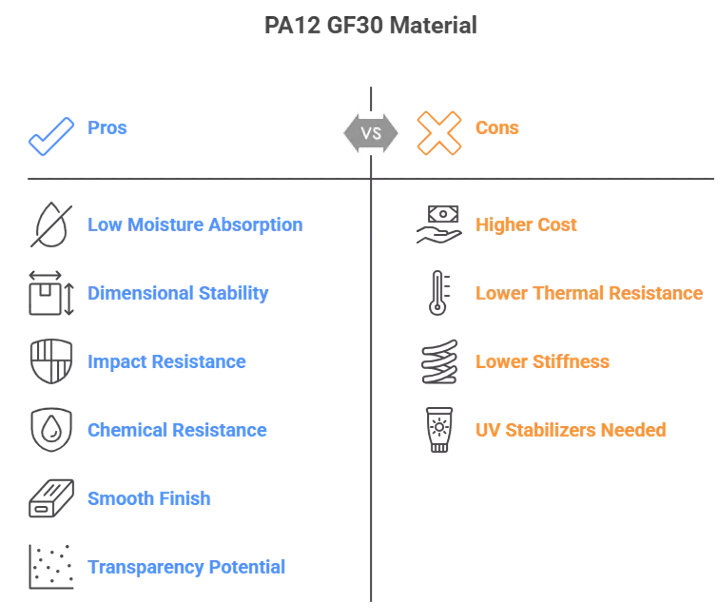

Advantages

- Ultra-Low Moisture Absorption – Reduces warpage and property loss over time, perfect for humid environments.

- Excellent Dimensional Stability – Maintains tight tolerances in precision parts.

- High Impact Resistance – Retains toughness despite reinforcement.

- Superior Chemical Resistance – Resists oils, fuels, and solvents.

- Smooth Surface Finish – Ideal for coloring and clean surfaces.

- Excellent Processability – Great for complex geometries and thin walls.

- Transparency Potential – Semi-transparent black appearance for sensor windows.

📌 Please explore the detailed mechanical data and color-matched grades in our Ardlon® LSG6 – PA12 GF30 Product Page.

Disadvantages

- Higher Material Cost – More expensive than PA6/PA66.

- Lower Thermal Resistance (vs. PA66 GF)

- Lower Stiffness – PA66 GF40+ may outperform in rigidity.

- Requires UV Stabilizers – For long-term outdoor use.

Comparison: PA12 GF30 vs PA6 GF30 vs PA66 GF30

| Property | PA12 GF30 | PA6 GF30 | PA66 GF30 |

|---|---|---|---|

| Water Absorption | ⭐ Extremely low (<0.25%) | ❌ High (~1.5%) | Moderate (~1.2%) |

| Dimensional Stability | ⭐ Excellent | Moderate | ✅Good |

| Toughness | ⭐ High flexibility even with GF | ⭐ High | Less flexibility |

| Cost | ❗ Higher (but better TCO overall) | ✅ Economical | Moderate |

📌 For broader comparisons, explore our Glass Fiber Reinforced Nylon Guide.

Real-World Case Studies: PA12 GF30 in Action

Case 1: Infrared Sensor Housing

Challenge: Conventional PA6 GF housings deformed due to moisture absorption.

Solution: Ardlon® LSG6-PA12 GF30 provided a semi-transparent black finish and retained shape.

Result: Reduced misalignment failures by 75%, lowered maintenance by 40%.

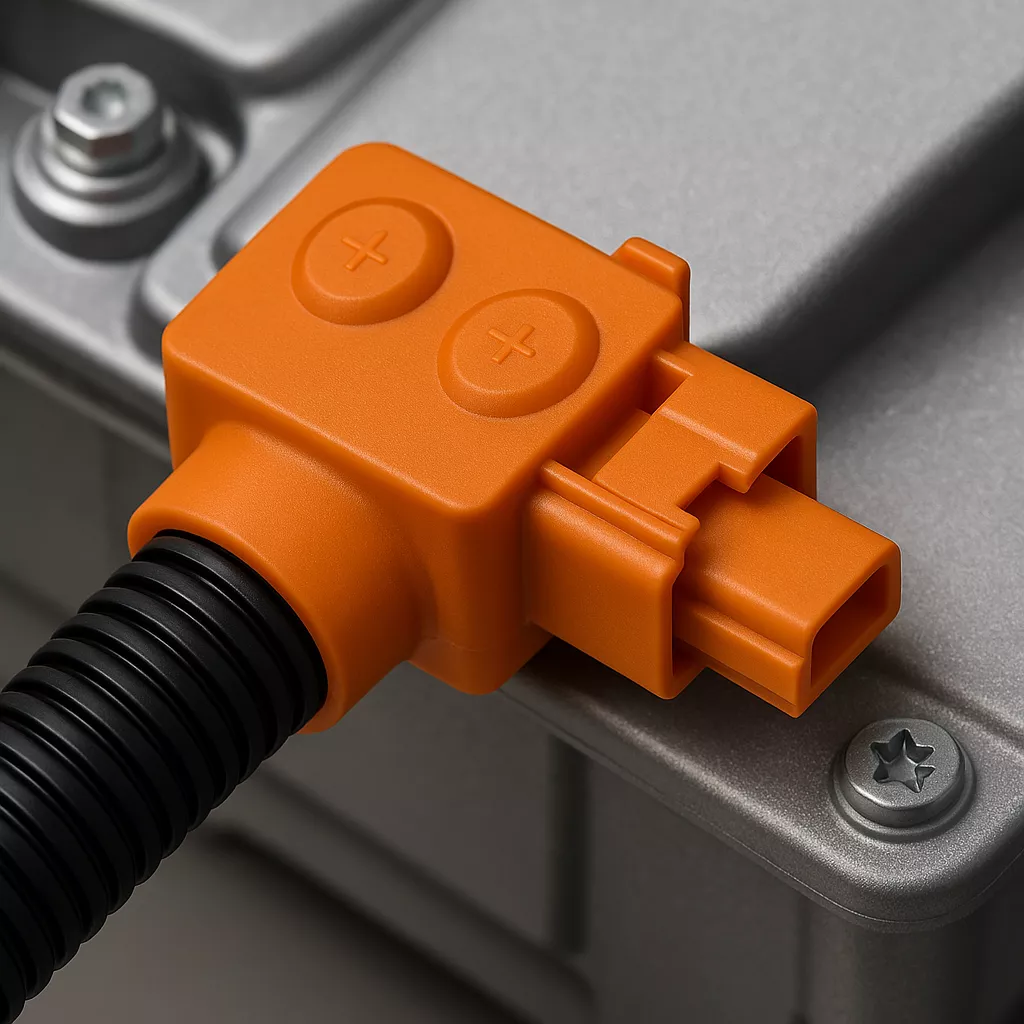

Case 2: Cable Harness Protection Cover (HV Module)

Requirement: Needed to resist oil/chemical exposure and tolerate high temperatures.

Why PA12 GF30: Stable under 120 °C continuous use with reliable snap-fit performance.

Outcome: Became the customer's standard for HV module wire harness covers.

Technical Data Snapshot (Ardlon® LSG6 – PA12 GF30)

| Property | Typical Values (Reference) |

|---|---|

| Density | 1.28 g/cm³ |

| Tensile Strength (ISO 527) | 110 MPa |

| Notched Charpy Impact | 21 kJ/m² |

| HDT @1.8 MPa | 170 °C |

| Saturated Water Absorption | <0.25% |

| Shrinkage (Flow Direction) | 0.3–0.5% |

📌 Full technical data sheet (TDS) and certifications are available on the PA12 GF30 Product Page.

Key Industrial Applications of PA12 GF

- Automation: Sensor housings, vision module brackets, servo motor covers

- Electrical Control: Cable management covers, battery insulation parts, terminal housings

- Fluid Systems: Pneumatic fittings, quick-connect joints, valve bodies

- Outdoor Electronics: Wireless device enclosures, smart streetlight parts

- Measurement Equipment: Portable scanners, laser positioning supports

Frequently Asked Questions (FAQ)

Q1: How much heat can PA12 GF30 withstand?

HDT values exceed 170 °C; recommended continuous use 120–140 °C.

Q2: What does “semi-transparent black” mean?

PA12 maintains a dark semi-translucent look, allowing IR or LED light to pass through for sensors.

Q3: Can PA12 GF30 replace aluminum?

Yes—for moderate structural loads, it can reduce weight and simplify assembly.

Q4: Is it easy to process?

Yes—excellent flowability, low warpage, and easy mold release even in thin-wall parts.

Looking for a PA12 GF30 Supplier?

Our flagship product Ardlon® LSG6 – PA12 GF30 is tailored for industrial-grade performance, offering:

- ✅ Low moisture absorption and high dimensional stability

- ✅ Excellent balance of stiffness and impact strength

- ✅ Semi-transparent black option for optical sensor applications

- ✅ Customizable formulas (UV resistance, color matching, GF tuning)

📞 Contact us today to request TDS, material samples, or a quotation.

Learn more about our commercial grades and download datasheets directly from the PA12 GF30 Product Page.