Overview: PA and POM at a Glance

Choosing between PA (polyamide/nylon) and POM (polyoxymethylene/acetal) isn't always straightforward. These two high-performance thermoplastics each offer unique benefits in strength, wear resistance, moisture stability, and dimensional accuracy—key traits in automotive, electronics, and industrial products.

In this guide, we break down the differences between PA6, PA66, and POM to help engineers and designers select the best material for their specific needs.

What Is PA (Polyamide, Nylon)?

PA, commonly known as nylon (e.g., PA6, PA66, PA12), is a strong, flexible thermoplastic with excellent fatigue resistance and toughness, especially with additives (impact modifiers) to modify the impact resistance. It's widely used in automotive parts, gears, housings, and textiles.

Common PA grades:

✅ Best for: Strength, toughness, temperature resistance

⚠️ Watch for: High moisture absorption, potential warpage

📌 For projects that need tailored performance, PA supports compounding with additives to achieve application-specific improvements.

What Is POM (Polyoxymethylene, Acetal)?

POM, often called acetal or Delrin®, is a rigid, low-friction engineering plastic known for excellent dimensional stability, low moisture absorption, and wear resistance.

✅ Best for: Precision gears, moving mechanical parts, sliding applications

⚠️ Watch for: Lower heat resistance vs. PA66; limited bonding without special treatments

Before we dive into performance comparisons, it's helpful to understand the chemical structure and classification of each material.

Chemical Structure & Material Types

PA (Polyamide) is a semi-crystalline polymer made from diamines and dicarboxylic acids (e.g., PA66) or amino acids (e.g., PA6). POM (Polyoxymethylene), on the other hand, can be found as a homopolymer (Delrin®) or copolymer, offering better thermal and hydrolytic stability.

Both materials belong to the family of engineering thermoplastics and are commonly referred to as nylon (PA) and acetal (POM).

📌 Check out more engineering plastics by reading our comprehensive guide.

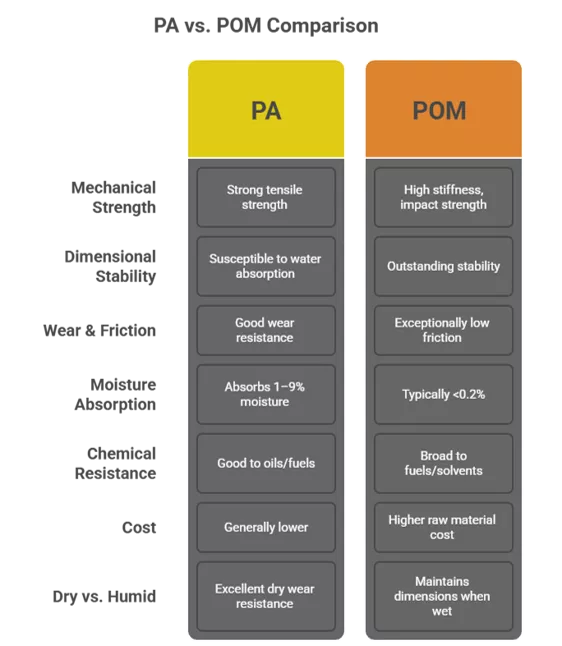

PA vs POM: Key Differences

1) Mechanical Strength

- PA: Strong tensile & flexural strength, especially when reinforced (e.g., PA66 GF30).

- POM: High stiffness and impact strength; maintains shape under stress.

👉 Verdict: PA excels in tensile strength; POM wins in rigidity and creep resistance.

2) Dimensional Stability

- PA: Susceptible to dimensional changes due to water absorption.

- POM: Outstanding dimensional stability—ideal for tight tolerances.

👉 Verdict: POM is superior for precision applications.

3) Wear & Friction

- PA: Good wear resistance; improves with additives.

- POM: Exceptionally low friction and self-lubricating behavior.

👉 Verdict: POM is the go-to for sliding parts and bearings.

4) Moisture Absorption

- PA: Can absorb 1–9% moisture, affecting strength & dimensions.

- POM: Typically <0.2%—very stable.

👉 Verdict: POM is better in humid or underwater environments.

📌 PA12 is the type of nylon that bearly absorbs moisture, learn the deep comparison and difference of PA6 vs PA12.

5) Chemical Resistance

- PA: Good resistance to oils and fuels but affected by acids and bases.

- POM: Broad resistance to fuels and many solvents.

👉 Verdict: Both perform well; POM has a slight edge in harsh environments.

6) Cost

- PA: Generally lower cost, especially in glass-filled or recycled forms.

- POM: Higher raw material cost; machining costs may vary.

👉 Verdict: PA offers better cost-performance in high-volume production.

📌 Check out the pros and cons of recycled nylon.

7) Dry vs. Humid Conditions

- PA: Excellent dry wear resistance; performance can degrade in humid environments due to moisture uptake (swelling, dimensional drift).

- POM: Consistently low friction and wear, with very low moisture absorption—maintains dimensions and tolerances even when wet.

👉 Verdict: For humid/underwater or moisture-variable conditions, choose POM; use PA in dry environments or when low-moisture grades/conditioning/additives are employed.

Material Property Comparison Table: PA66 vs POM

| Property | PA66 (Nylon 66) | POM (Acetal/Delrin®) |

| Tensile Strength (MPa) | 80–90 | 60–70 |

| Elongation at Break (%) | 50–150 | 20–40 |

| Flexural Modulus (MPa) | 2,800–3,000 | 2,500–3,200 |

| Water Absorption (%) | 1.5–9.0 | <0.2 |

| Coefficient of Friction | 0.3–0.4 | 0.2–0.3 |

| Continuous Use Temp (°C) | 100–120 | 90–100 |

| Melting Point (°C) | 265 | ~175–180 |

| Density (g/cm³) | 1.14 | 1.41 |

📌 Discover the Different Types of Nylon for choosing the right material.

Application-Based Material Selection Guide

| Requirement | Choose PA (Nylon) | Choose POM (Acetal) |

| High tensile load | ✅ Structural brackets, engine covers | ⚠️ Moderate load only |

| Dimensional precision | ⚠️ May swell in humid environments | ✅ Best for tight-tolerance parts |

| Humid or underwater environment | ⚠️ Water absorption may impact performance | ✅ Excellent stability in wet conditions |

| Sliding or rotating parts | ✅ With additives or oil-filled grades | ✅ Natural low friction & wear resistance |

| Cost-sensitive, high-volume | ✅ Glass-filled or recycled grades available | ⚠️ Higher raw material cost |

| Shock resistance / impact damping | ✅ Superior toughness & energy absorption | ⚠️ Can be brittle under sudden impact |

Which One Should You Choose? (At a Glance)

| Feature | PA (Nylon) | POM (Acetal) |

| Strength | ✅ High | ✅ Moderate–High |

| Stiffness | ✅ Moderate | ✅ High |

| Water Absorption | ❌ High | ✅ Low |

| Friction & Wear | ✅ Good | ✅ Excellent |

| Dimensional Stability | ❌ Lower | ✅ Excellent |

| Cost | ✅ Lower | ❌ Higher |

✅ Choose PA for: High strength, impact resistance, cost-effectiveness

✅ Choose POM for: Precision, sliding wear parts, dimensional accuracy

PA vs POM – Frequently Asked Questions

Is POM stronger than nylon?

POM is stiffer and offers better dimensional stability, but PA is generally stronger in tensile performance.

Can POM replace nylon?

In some cases, yes—especially where moisture stability or low friction is key, such as gears. Nylon remains better for high-load applications.

Is nylon or acetal better for gears?

POM is preferred for precision and low-friction gears; PA is better for higher strength and shock loading.

Which material is more water-resistant?

POM absorbs significantly less moisture than nylon and is more water-resistant.

Which one is cheaper, PA or POM?

PA is typically more economical, especially when using filled or recycled grades.

📌 If you're also evaluating polymers as metal substitutes, see our guide to top plastics for metal replacement for strength-to-weight and cost trade-offs.

Conclusion

Both PA and POM are valuable engineering thermoplastics with distinct strengths. If your project demands tight tolerances and low friction, POM is the better fit. If you're prioritizing strength and cost efficiency—especially with reinforcement—PA is often the smarter choice.

Not sure whether PA66 GF30 or POM copolymer suits your application? At All Around Compounding, we offer tailored material solutions backed by technical expertise and real-world performance data.

Need Help Choosing?

Contact us today for a material consultation and get the most out of your application design.