Recycled nylon has become a popular choice for manufacturers seeking more sustainable solutions — it helps not only the environment but also represents the responsibility to society. While recycled PA6 and PA66 offer environmental and cost advantages, one of the biggest concerns among engineers is reduced impact resistance compared to virgin-grade materials.

So, how can we overcome this challenge without compromising recyclability? Let's explore practical strategies to enhance impact strength in recycled nylon compounds.

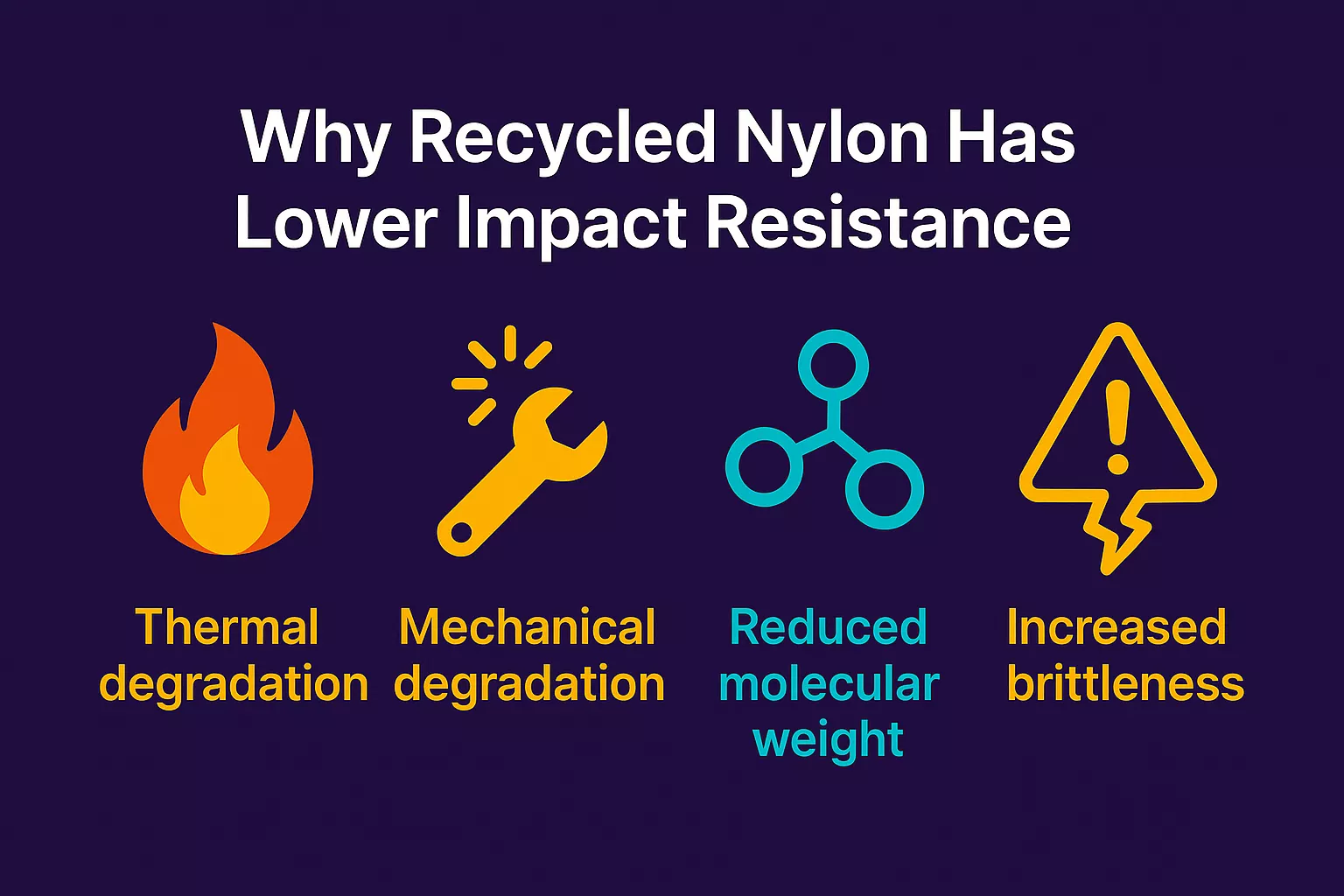

Why Recycled Nylon Has Lower Impact Resistance

During the recycling process, nylon undergoes thermal and mechanical degradation. This leads to:

- Reduced molecular weight

- Increased brittleness

- Greater susceptibility to micro-cracks under stress

Numerically speaking, impact-modified PA6 can reach over 100 kJ/m² in Notched Izod impact strength, while unreinforced virgin grade PA6 averages around 13 kJ/m², and recycled grades may drop below 5 kJ/m².

Additionally, contamination from other polymers, fillers, or moisture can worsen performance — especially in demanding applications like housings, gears, or structural parts.

Why Recycled Nylon Has Lower Impact Resistance

1. Use Rubber Modifiers to Toughen Recycled Nylon

The most common and effective method is to blend recycled nylon with impact modifiers such as:

- EPDM-g-MA (ethylene-propylene-diene rubber grafted with maleic anhydride)

- POE-g-MA (polyolefin elastomer grafted with maleic anhydride)

These elastomeric additives increase the material's ability to absorb energy without cracking. Recommended dosage is around 10–30%, depending on the base resin and target application. Anhydride grafting enhances compatibility between the nylon matrix and rubber phase, resulting in better dispersion and consistent toughness.

POE-g-MA (polyolefin elastomer grafted with maleic anhydride)

2. Mix Virgin Nylon to Improve Impact and Flow

If your application allows, blending recycled nylon with a percentage of virgin nylon can improve:

- Impact resistance

- Flowability

- Consistency

A 70/30 or 80/20 (recycled/virgin) blend is commonly used to strike a balance between performance and cost.

Virgin Nylon can help Improve Impact and Flow of Recycled Nylon

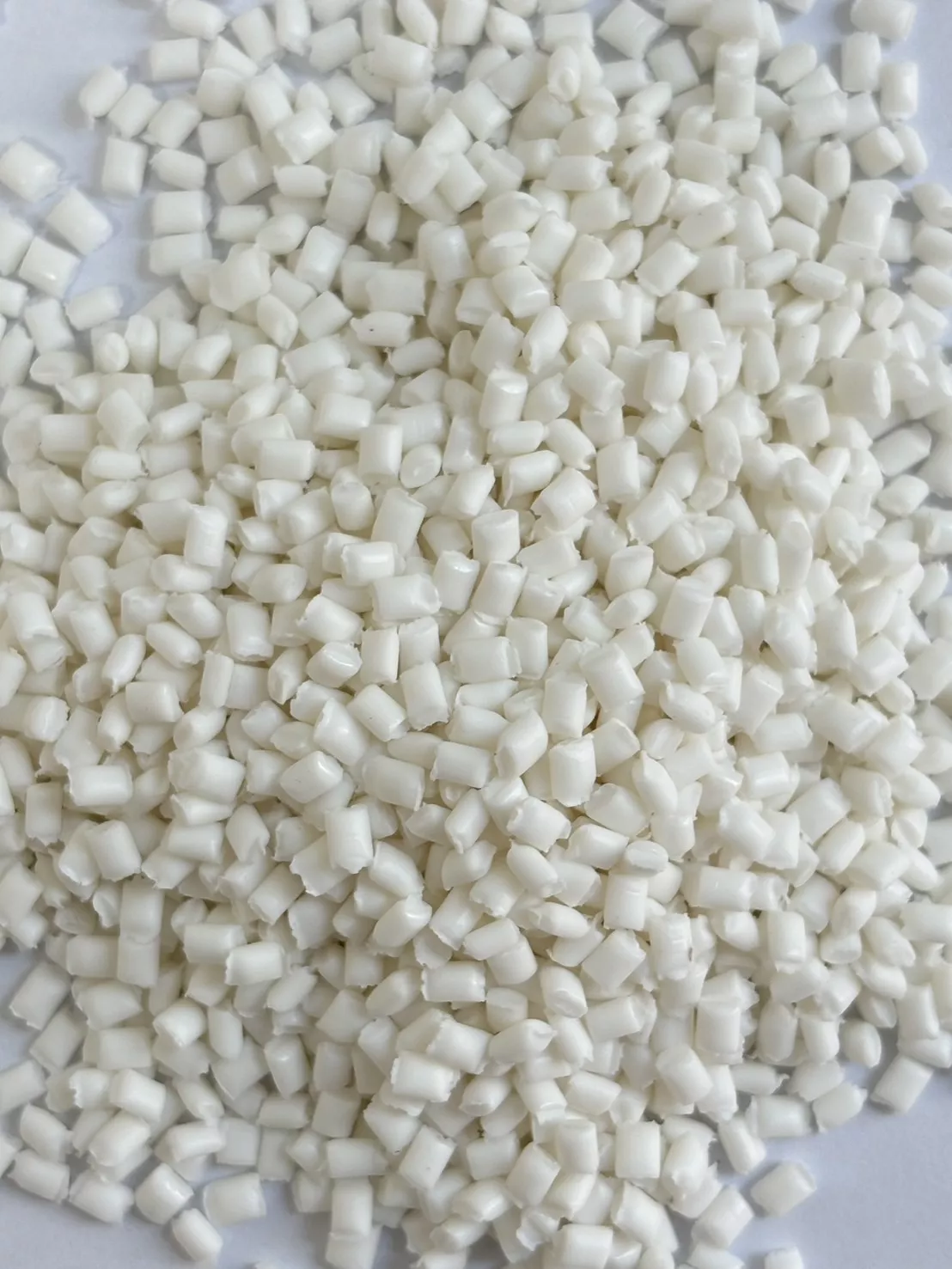

3. Pre-Mixed Toughened Nylon Blends: A Shortcut

Another effective approach is to blend recycled nylon with impact-modified nylon compounds. These are typically pre-formulated PA6 or PA66 materials that already contain rubber modifiers like POE-g-MA or EPDM-g-MA.

This method offers:

- Improved toughness and ductility

- Consistent impact performance

- Simplified processing, since the modifier is already compounded

Example: A 25% blend of impact-modified PA6 into recycled PA6 can significantly raise the Izod impact strength — sometimes from below 5 kJ/m² up to 25–40 kJ/m², depending on the formulation.

This approach is especially helpful when:

- You want to avoid compounding from scratch

- You need a more predictable mechanical profile

- You're working with limited compounding facilitie

Impact Modified Nylon Pellets

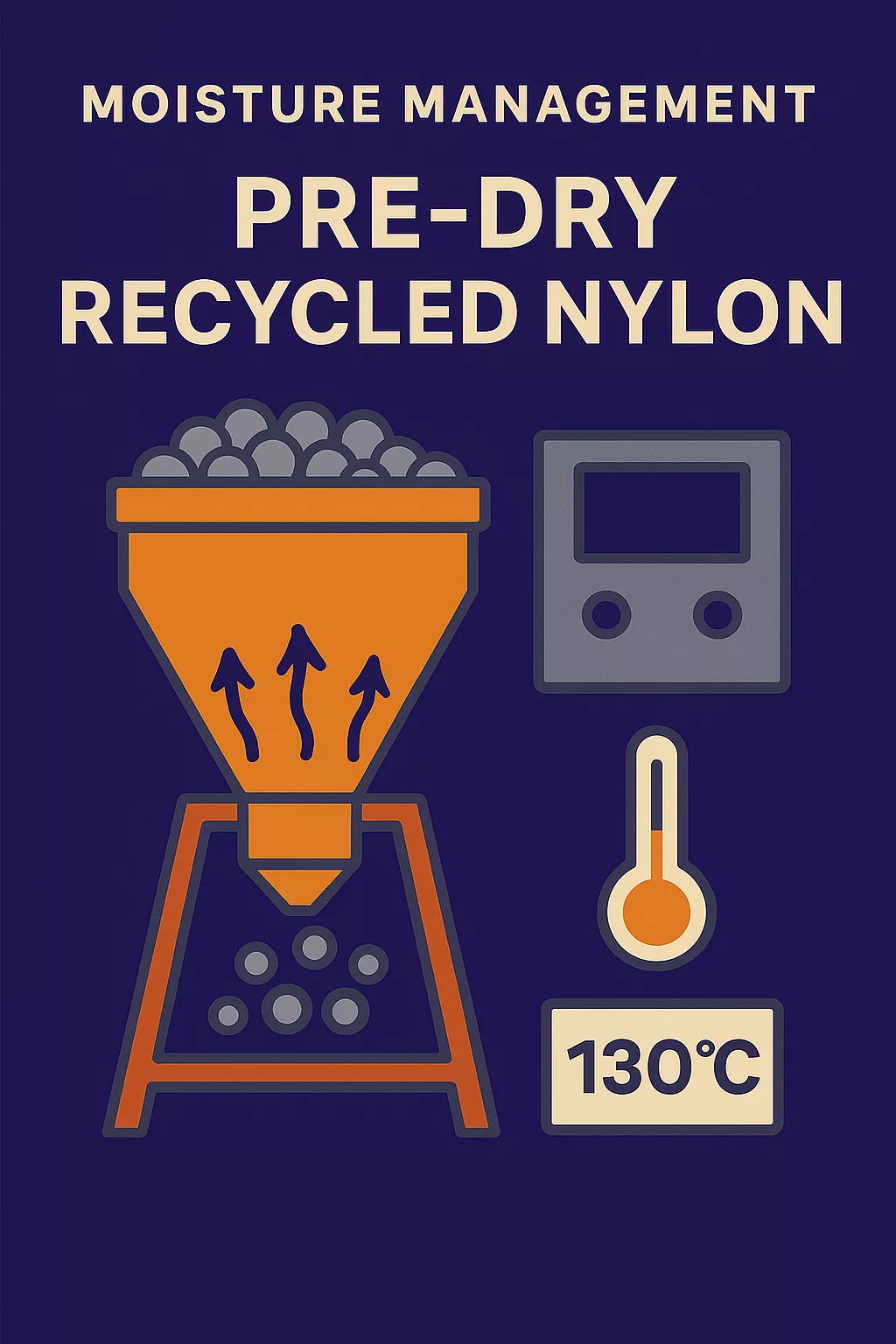

4. Moisture Management: Key to Prevent Brittleness

Recycled nylon is highly hygroscopic. Moisture during processing or in the final product can:

- Lower molecular weight

- Introduce voids or weak spots

Solution: Always pre-dry recycled nylon before molding. We would suggest drying the materials at 130°C for 4–6 hours). Moisture content should be <0.2-0.3% before processing.

Why does pre-dry matter to nylon materials? Discover What is nylon?

Moisture Management – Pre-Dry Recycled Nylon to Prevent Brittleness

5. Compatibilizers for Tougher Polymer Blends

If blending recycled nylon with other polymers (e.g., PP, PET), compatibilizers like maleic anhydride grafted polymers (e.g., MAgPP, MAgPE) can:

- Improve interfacial adhesion

- Prevent phase separation

- Enhance impact resistance

However, these compatibilizers can significantly affect other mechanical properties, such as tensile and flexural strength. Therefore, it is critical to consider the final application requirements before incorporating them.

Maleic Anhydride Grafted Polymers Granules

Real-World Example of Improvement:

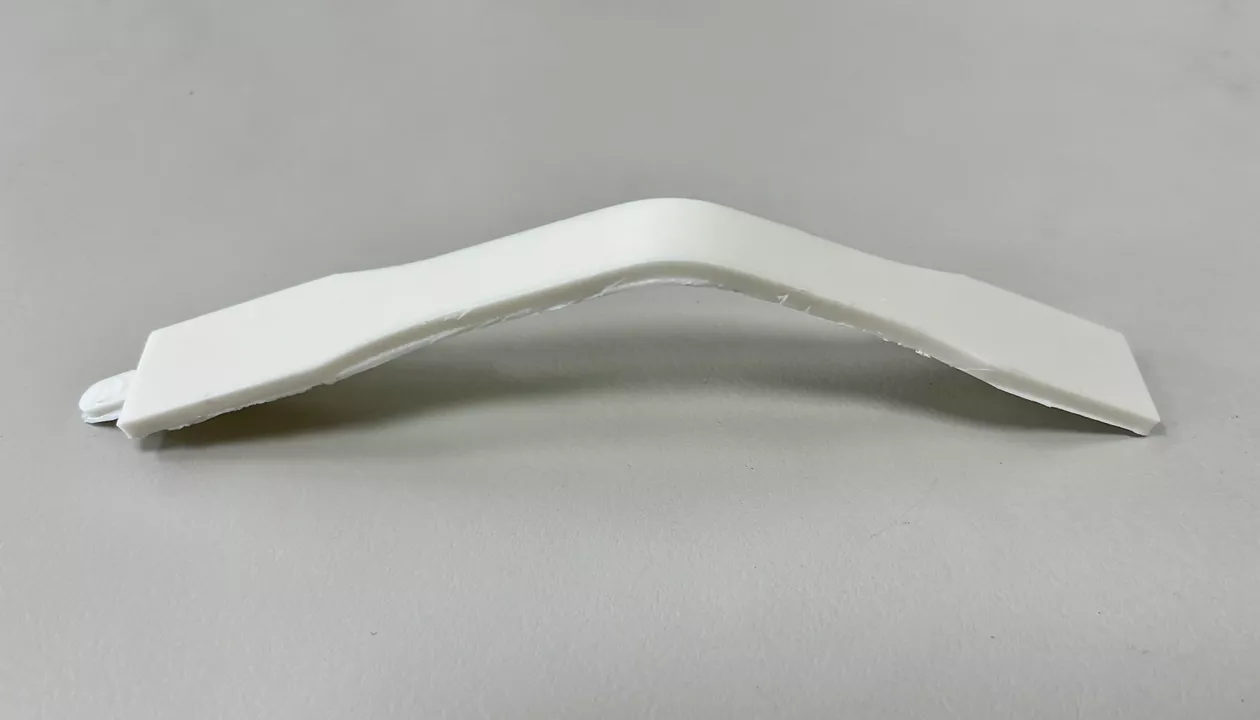

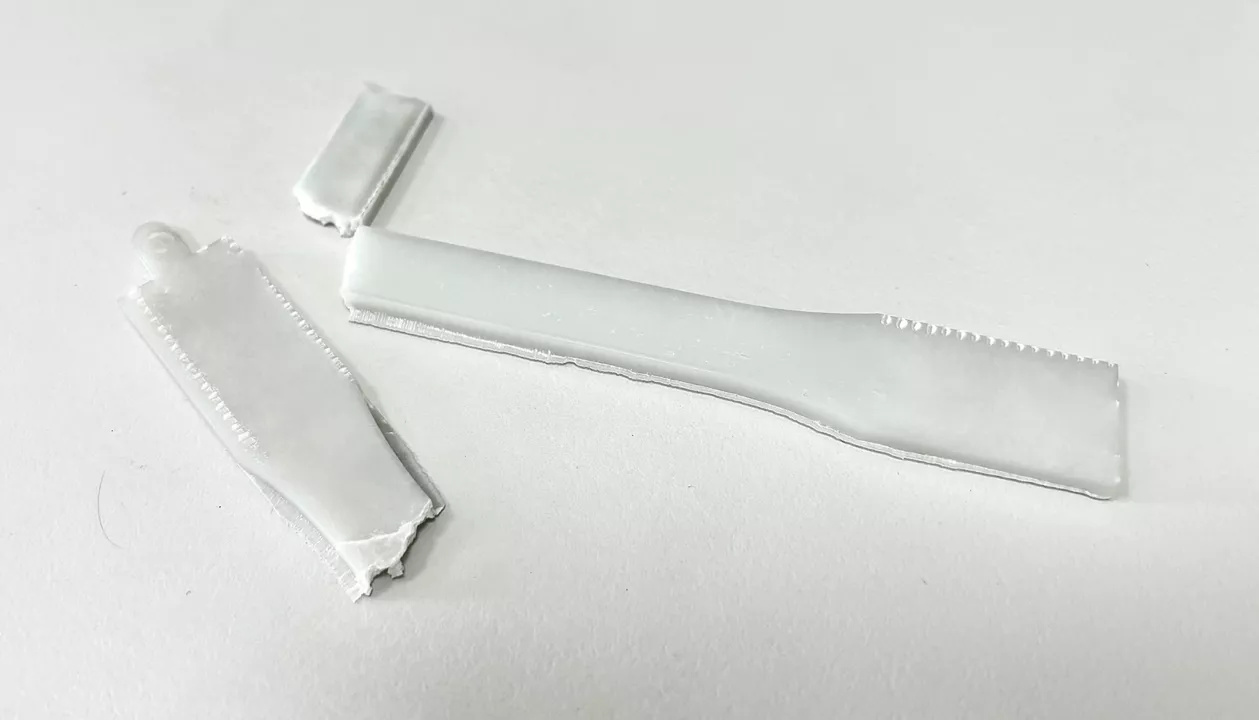

At All Around Compounding (All Around Polymer Co., Ltd.), we helped a customer replace virgin nylon with a recycled PA6 + Impact Modifier blend for power tool housings and drain cleaning tool.

The results are:

✔️ Impact strength improved by 2.5 times

✔️ No visual surface defects

✔️ Passed drop and fatigue tests under real-use conditions

Flexible Drain Cleaning Tools – Hair Clog Remover

Final Thoughts

Improving impact resistance in recycled nylon compounds is not a one-size-fits-all task. It requires a smart combination of:

- Rubber modifiers

- Proper drying techniques

- Filler and blend optimization

- Compatibilization when needed

By understanding the material's limitations and leveraging the right additives, recycled nylon can also reach the expected properties.

Improving Impact Resistance in Recycled Nylon Compounds

Ready to Customize a Toughened Recycled Nylon Compound?

At All Around Compounding (All Around Polymer Co., Ltd.), we specialize in customizing recycled nylon solutions with enhanced mechanical properties — including impact-resistant, glass fiber, and mineral-reinforced grades.

Let's create a solution tailored to your needs.

👉 Contact us today to request a trial sample or technical consultation.