Plastics are among the most versatile materials in modern industry. From packaging to high-performance automotive components, they offer a wide range of properties to suit different needs. At All Around Compounding (All Around Polymer Co., Ltd.), we help customers make informed decisions by understanding how plastic raw materials are categorized based on structure, origin, performance, processing method, and end use.

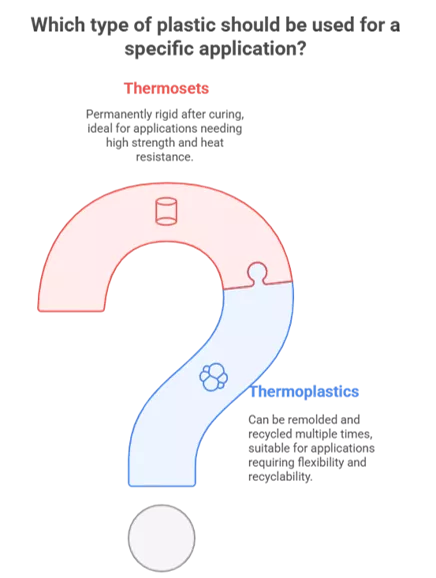

1. Classification by Polymer Structure: Thermoplastics vs Thermosets

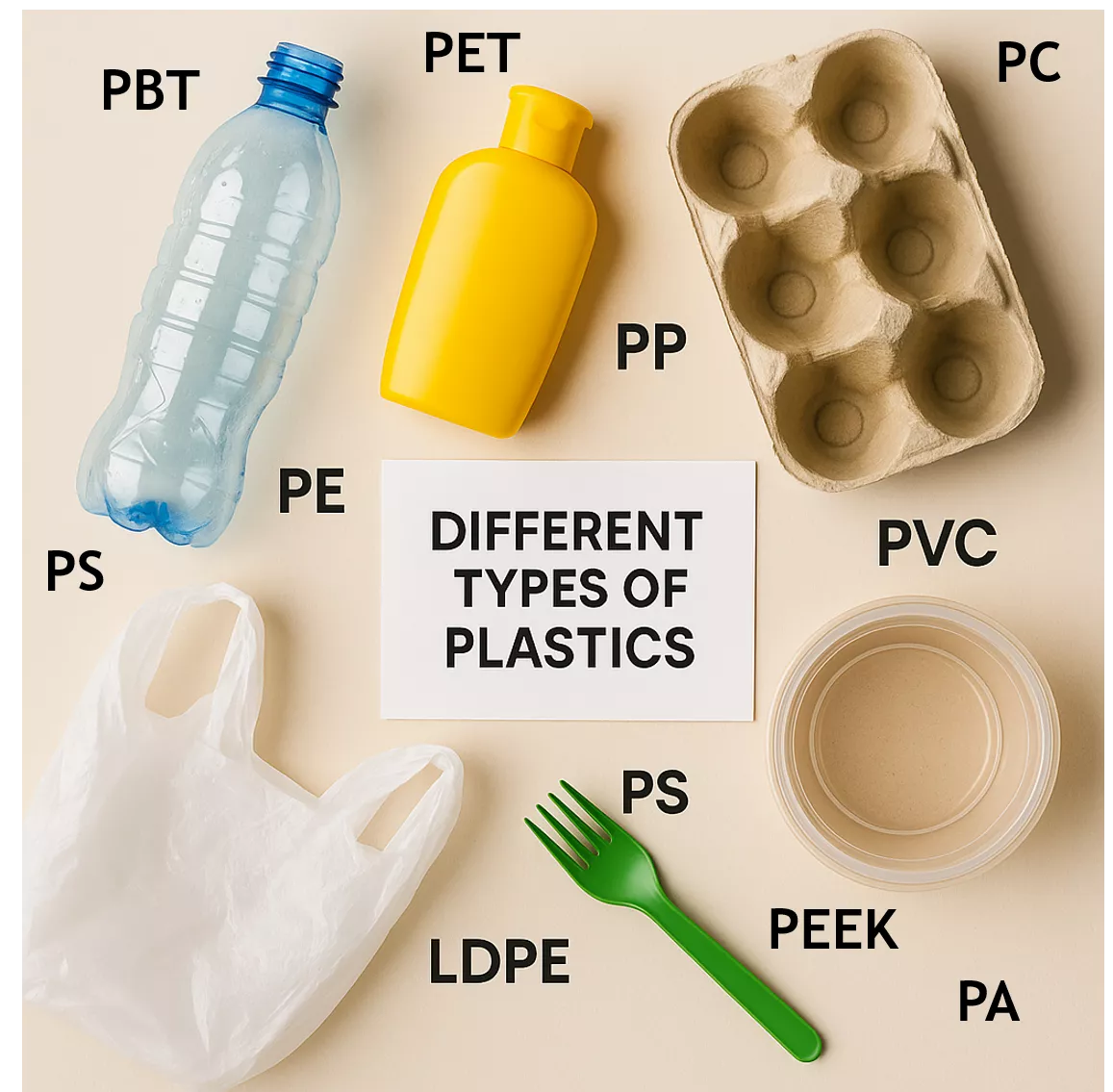

Thermoplastics soften when heated and harden when cooled. This allows them to be remolded and recycled multiple times. Common thermoplastics include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyamide (PA)

- Polycarbonate (PC)

- Polybutylene Terephthalate (PBT)

- Polyethylene Terephthalate (PET)

Thermosets, on the other hand, undergo a chemical curing process that makes them permanently rigid. Once set, they cannot be melted again. Examples include:

- Epoxy resins

- Phenolic resins

- Unsaturated polyesters

- Rubber

Thermosets are often used when heat resistance and dimensional stability are essential.

Quick Comparison: Thermoplastics vs Thermosets

|

Properties |

Thermoplastics | Thermosets |

| Remoldability | ✅ Re-meltable and re-shapeable | ❌ Cannot be re-melted after curing |

| Recyclability | ♻️ Easy to recycle | 🚫 Difficult or impossible to recycle |

| Processing Temp | Moderate (e.g., 200–300°C) | Often higher; requires curing |

| Mechanical Properties | Moderate; modifiable with additives | High strength and dimensional stability |

| Initial Cost | Generally lower | Higher, but more stable over time |

| Typical Applications | Packaging, automotive, electronics housings | Circuit boards, adhesives, high-heat parts |

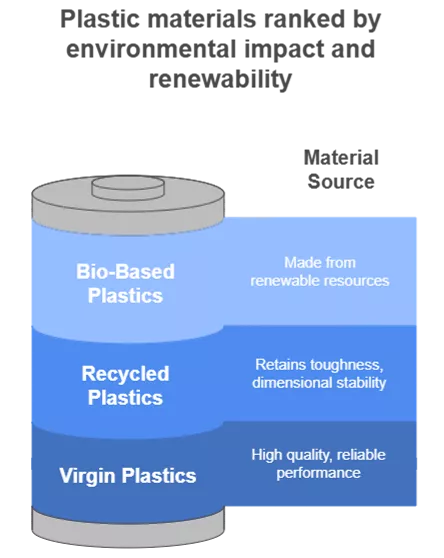

2. By Source: Virgin, Recycled, and Bio-Based Plastics

Virgin (Prime) Materials: These are produced from petrochemical feedstocks and provide consistent, high-quality performance—ideal for applications where reliability is essential.

Recycled Plastics: Post-consumer and post-industrial recycled plastics are increasingly used due to their environmental benefits. At All Around, our recycled PA6 and PA66 compounds retain excellent toughness and dimensional stability.

Bio-Based Plastics: Made from renewable resources like corn or sugarcane, these materials—such as PLA and bio-PE—are gaining traction under stricter sustainability regulations.

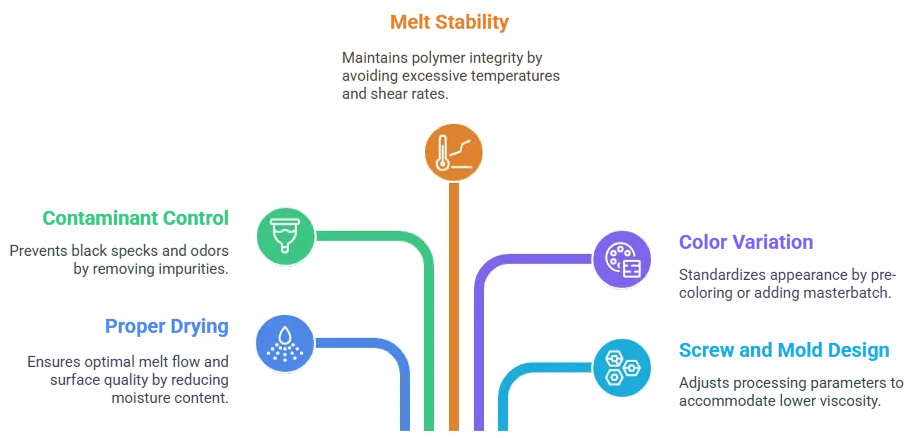

Processing Considerations for Recycled Plastic Compounds

While recycled plastics such as PCR (Post-Consumer Recycled) and PIR (Post-Industrial Recycled) materials offer sustainability and cost advantages, they also require additional care during processing to ensure consistent quality.

Key factors to consider when working with recycled compounds like recycled PA6 or PA66 include:

- Proper Drying: Moisture content can significantly affect melt flow and surface quality. Recycled nylons should be dried to ≤0.1% moisture before processing to prevent voids or hydrolysis.

- Contaminant Control: Impurities from mixed polymer streams or additives (such as PVC, PET, or metal traces) can cause black specks, odors, or degraded mechanical properties.

- Melt Stability: Recycled materials often have lower molecular weight and reduced thermal stability. Avoid excessive barrel temperatures and shear rates that could further degrade the polymer.

- Color Variation: Natural-color recycled plastics may show slight color inconsistencies. Consider pre-coloring or adding a masterbatch to standardize the appearance.

- Screw and Mold Design: Adjust back pressure and screw speed to accommodate lower viscosity. Hot runner systems should be carefully tuned to prevent material degradation.

At All Around Compounding (All Around Polymer Co., Ltd.), we address these challenges by thoroughly controlling input quality and tailoring each recycled compound to meet specific processing requirements. Our recycled nylon grades are optimized for injection molding, extrusion, and secondary processing needs.

Learn more about Recycled Nylon: Turning Waste into Value

3. By Performance Characteristics

Plastics can be customized with additives to enhance specific properties:

- Glass Fiber or Mineral Fillers for added stiffness and reduced shrinkage.

- Impact Modifiers for improved toughness and durability.

- Flame Retardants to meet safety standards in electronics and automotive.

- UV Stabilizers for outdoor applications exposed to sunlight.

These performance enhancements give plastics the versatility to meet demanding industry standards—whether the goal is improved rigidity, durability, or environmental resistance.

In the following section, we take a closer look at two of the most widely used modification strategies in engineering plastics: glass fiber reinforcement and impact modification. While both are designed to enhance mechanical performance, they differ significantly in purpose, effect, and application. Selecting the appropriate modification is essential for optimal performance and cost-efficiency.

At All Around Compounding (All Around Polymer Co., Ltd.), we offer a full range of customized formulations, including:

These materials are designed to meet specific performance targets across automotive, consumer, and industrial applications.

Comparison of Glass Fiber-Reinforced vs. Impact-Modified Nylon Materials

| Feature | Glass Fiber Reinforced | Impact Modified |

| Primary Purpose | Increases stiffness and structural strength | Enhances toughness and impact resistance |

| Typical Additive Content | 10–50% glass fiber | 5–15% elastomer (e.g., POE, TPE) |

| Tensile/Flexural Strength | High | Moderate |

| Impact Resistance | Lower, more brittle | Excellent, especially in low temperatures |

| Surface Appearance | Rougher, visible fiber texture | Smoother surface |

| Dimensional Stability | Excellent, low shrinkage | Moderate; shrinkage needs to be managed |

| Common Applications | Brackets, engine covers, structural parts | Tool housings, clips, consumer device enclosures |

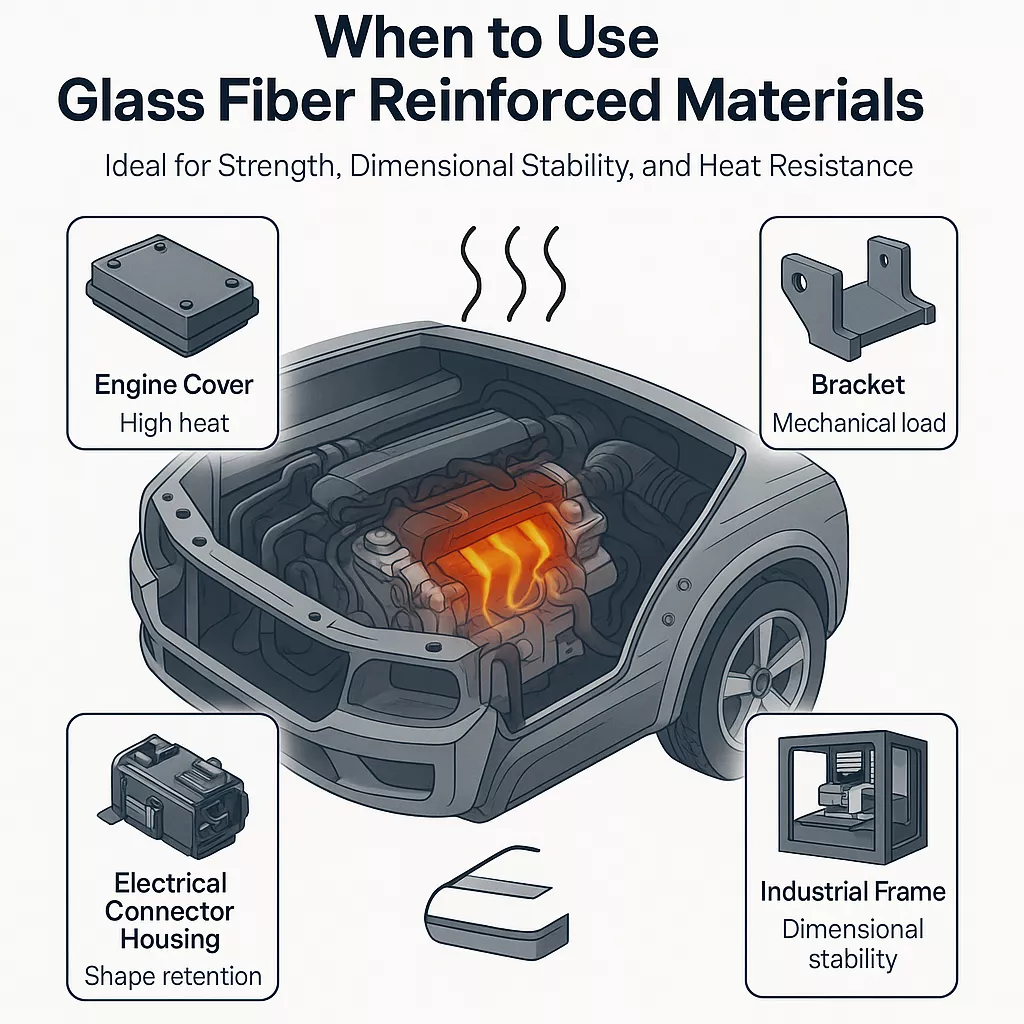

Application Guidance A: When to Use Glass Fiber Reinforced Materials

If your product requires high rigidity, dimensional stability, and structural strength, glass fiber reinforced materials like PA66 GF30 are ideal. These are commonly used in:

- Engine covers and under-hood components

- Brackets and mounting structures

- Electrical connector housings

- Industrial equipment frames

These parts must retain shape and strength under heat or load, where the stiffness of glass fiber provides a clear advantage.

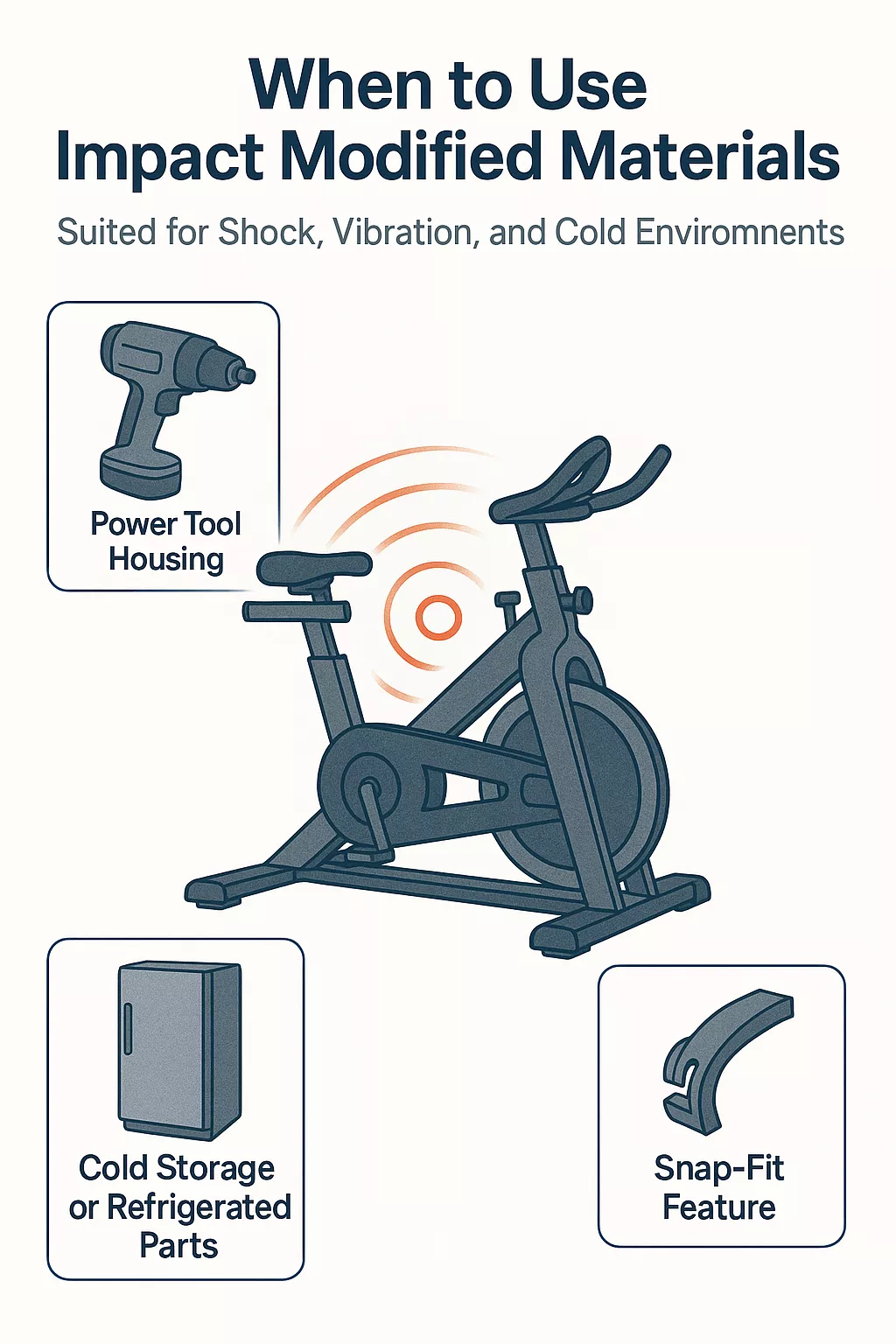

Application Guidance B: When to Use Impact Modified Materials

If your application is exposed to shock, vibration, or repetitive mechanical stress, especially in cold environments, consider using impact modified plastics such as POE-toughened PA6. Typical use cases include:

- Power tool housings

- Outdoor gear and equipment

- Cold storage or refrigerated parts

- Snap-fit features or flexible mounting clips

These products benefit from high ductility and crack resistance, and would be prone to brittle failure if made with stiff GF-reinforced materials.

4. By Processing Method

Different plastic materials are designed for specific manufacturing technologies:

- Injection Molding

- Extrusion

- Blow Molding

- Rotational Molding

- 3D Printing (Filament or Resin)

Each method requires unique flow characteristics, temperature resistance, and shrinkage control. For instance, impact-modified nylon for injection molding is engineered to provide superior toughness and dimensional stability in molded parts—making it ideal for components that must withstand repeated stress or low-temperature impact.

5. By Application Area

Plastic materials are often selected and engineered according to their end-use applications:

- Automotive: PA66 GF30, PBT, PP blends for engine covers, brackets, and interiors.

Learn more in our Automotive Nylon Applications

- Electrical & Electronics: Flame-retardant PC, PBT, and PA compounds.

- Consumer Goods: Lightweight, colorful, and cost-efficient plastics such as PC, PP, or ABS are commonly used in casings and enclosures. They are also used in specific automotive applications—like headlight materials—where clarity, impact strength, and thermal resistance are critical.

- Industrial Packaging: Durable PE, recycled PP, MAgPE or MAgPP-based composites.

Maleic Anhydride Grafted Polymers Granules

Frequently Asked Questions

Q1: What are the main types of plastic raw materials?

A: Plastics are categorized into thermoplastics, thermosets, virgin, recycled, and bio-based materials based on structure and source.

Q2: Why are thermoplastics widely used?

A: They can be reprocessed multiple times, making them ideal for recyclable and high-volume applications.

Q3: What is the difference between virgin and recycled plastics?

A: Virgin plastics are made from new petrochemicals, while recycled plastics are made from reused plastic waste—offering lower costs and environmental benefits.

Q4: What plastics are used in automotive components?

A: PA66 GF30, PBT, and modified PP are widely used for their durability and heat resistance.

Q5: How are plastic materials selected for processing methods?

A: Material properties like melt flow index, thermal stability, and shrinkage are matched to the requirements of molding or extrusion methods.

Partner With a Trusted Compounder

At All Around Compounding (All Around Polymer Co., Ltd.), we don't just sell plastic materials — we solve material challenges. From virgin engineering plastics to recycled and specialty blends, we work with clients all around the world to customize materials for injection molding, extrusion, and more.

Contact us today to explore our wide product range and get expert support for your next project.