As the automotive industry evolves, every component significantly impacts a vehicle's performance and aesthetics. Car headlights, often overlooked, are crucial for both structural integrity and visual appeal. This article focuses on the section where the light bulbs are seated and explores the key considerations in choosing the right material for car headlight brackets and similar components.

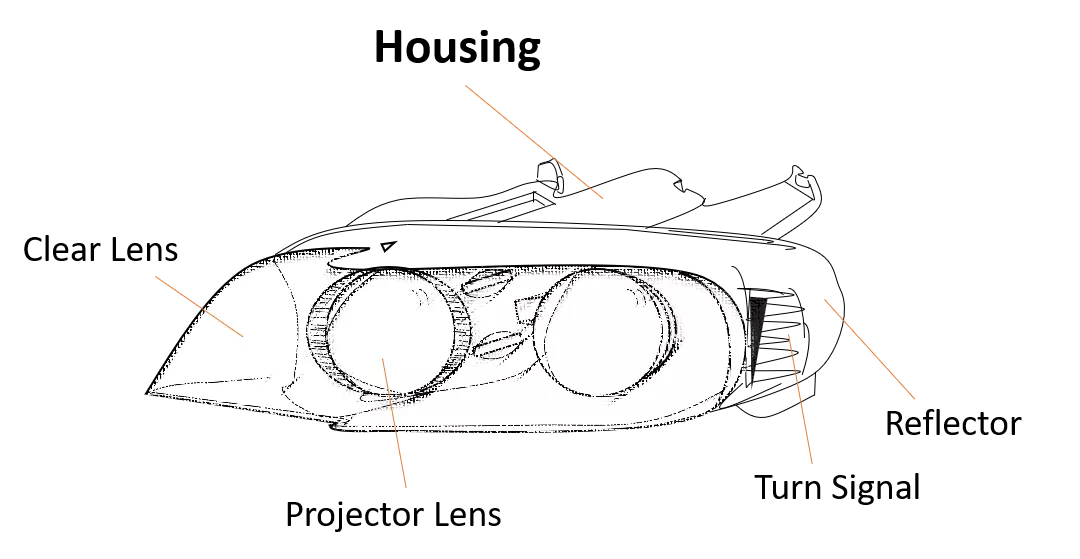

Automotive Headlight Housings

Choosing the right materials is vital for reducing manufacturing defects, optimizing injection molding cycles, enhancing moldability, extending tool life, and reducing weight for better fuel efficiency. These factors collectively influence both the quality and economics of production.

Fundamental Considerations

Before diving into specific materials, let's examine the fundamental considerations in selecting materials for car headlight bases.

- Structural Integrity

- Thermal and Electrical Properties

- Chemical Resistance

Injection Molding Dynamics

The injection molding process deserves special attention. Car headlight housings often have complex shapes, requiring materials with high fluidity to ensure seamless filling of intricate mold cavities. This characteristic is crucial to avoid surface defects and complications during subsequent processes like electroplating.

Aesthetics and Surface Finishes

Aesthetic considerations are essential in the automotive industry. Visible components like car headlight housings benefit from materials compatible with electroplating, achieving a polished, uniform surface finish that enhances overall appearance and provides corrosion resistance.

- Surface Uniformity

- Electroplating Compatibility

Headlight housing BEFORE and AFTER electroplating

Material Recommendations

1. Nylon + Mineral Filler (MF)

- High Fluidity

- Structural Benefits

- Heat Deflection Temperature (HDT)

2. Polybutylene terephthalate (PBT)

- High Fluidity and Dimensional Stability

- Glossy Surface

- Heat Deflection Temperature (HDT)

3. Nylon-6 Nanocomposite

- Electroplatable without coating

- Cost Efficient and Eco-Friendly

- Superior properties

Conclusion

Selecting materials for car headlight bases involves considering structural integrity, injection molding dynamics, and aesthetic priorities. Nylon and polybutylene terephthalate (PBT) are recommended for their high fluidity, structural integrity, and electroplating compatibility. By considering these materials, manufacturers can create headlight bases that seamlessly combine form and function.

At All Around Polymer Co., we specialize in providing cutting-edge materials for automotive applications. With over 30 years of industry experience, we offer a range of materials, including Nylon with Mineral Filler, polybutylene terephthalate (PBT), and Nylon-6 Nanocomposite, catering to diverse industry needs. Our focus on innovation, quality, and sustainability drives us to deliver materials that exceed expectations and drive success for our customers.

Partner with us to unlock the full potential of advanced materials and elevate your automotive components to new heights of performance and durability. Contact us at info@allaroundpolymer.com or download our catalog for comprehensive information.