Ardlon® MAgPP - ENP

An excellent bridging agent material

Applicable to various kinds of plastic materials

Polypropylene (PP) is a non-polar polymer, which results in poor surface adhesion with glass fibers, leading to ineffective manifestation of its properties. However, ENP (Maleic Anhydride-Grafted PP, also known as MAgPP) produced by AAP Corp. can effectively address this issue.

ENP is a modified polypropylene used as a bridging agent between polypropylene and glass fibers. By adding ENP in the appropriate proportions, the adhesion between polypropylene and glass fibers can be significantly improved. This enhanced bonding helps further enhance the mechanical properties of the material, such as rigidity, elongation, surface gloss, and processability.

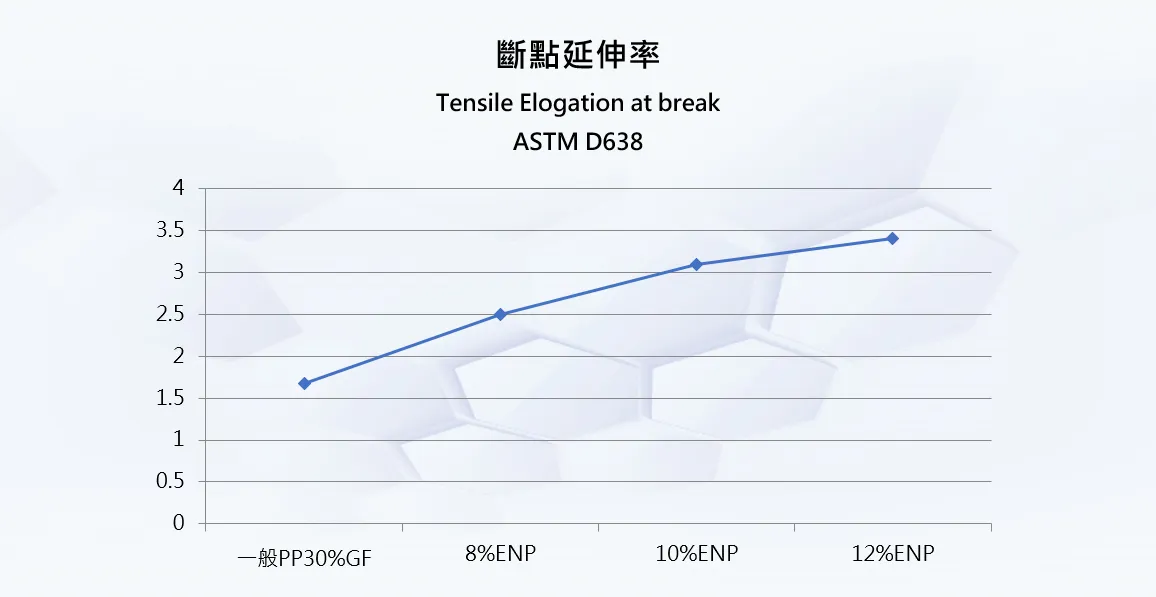

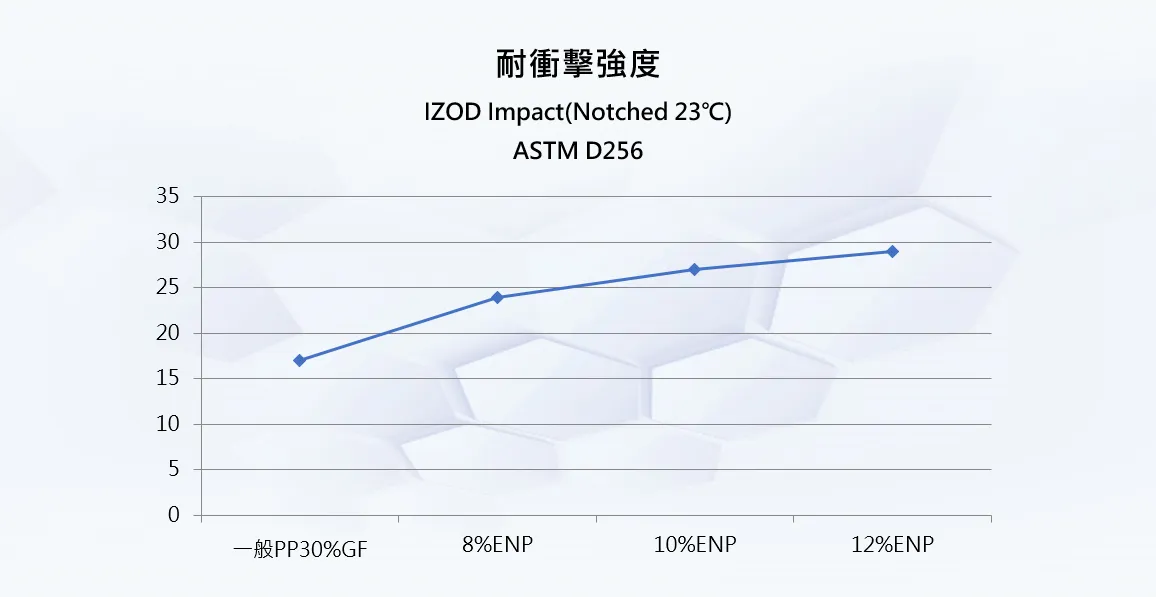

By adding approximately 10% of ENP, not only can the tensile strength be increased by 50%, but the tensile elongation at break rate and IZOD can also be effectively improved by 10%-20%. Additionally, due to its high melting index, the surface glossiness and smoothness of PP+GF materials can be significantly improved, helping to mitigate the issue of floating fiber.

ENP serves as an excellent bridging agent material, providing an important solution for enhancing the performance of polymer materials. By incorporating ENP, we can overcome the adhesion issues between polypropylene and glass fibers, thereby elevating the overall performance and quality of the materials.

An excellent bridging agent material for PP and glass fiber

Enhancing the mechanical properties of the material

High Compatibility

Excellent compatibility and polarity with various polyolefins

Easy To Process

Excellent flow properties achieve good packing capacity

Other Features

Warm touch and elasticity, high optical properties, high heat sealability and transparency

Recommendations

Adding 8% to 12% ENP to the composite material can increase the tensile strength by 50% to 100%, while the elongation can be increased by 30% to 50%, and the impact strength can be increased by 30% to 50%.

The results of adding ENP in different proportions to PP+30%GF